Momy985

Guest

I have always used thindesign in which development fits:

I did some tests and noticed that:

if I extrude the profile and then the development by inserting the desired k factor the development coincides with that of thinkdesign, if instead I extrude the development and then the piego I find some mm differences on the folds different from 90°.

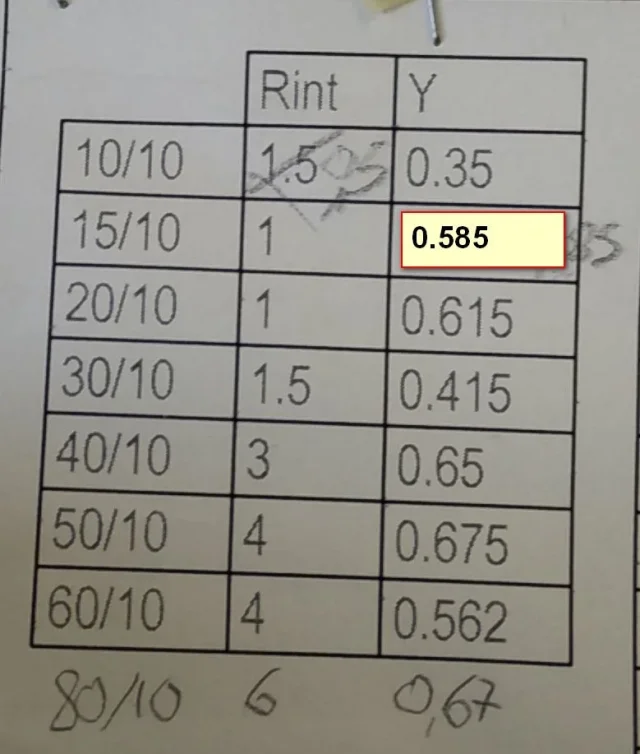

this is the table for calculating the position of the neutral axis and as a result of the k factor I use for thikdesign:

sheet thickness 0÷2.5 with internal radius equal to thickness --> living edge only on folds of 90° for different angles is considered 1/3 of the psessor.

sheet thickness 3÷6 with internal radius equal to the thickness --> 1/3 of the thickness.

sheet thickness 7÷12 with internal radius equal to thickness --> 0.4 of thickness.

sheet thickness >12 with internal radius equal to thickness --> 0.5 of thickness.

sheet thickness any with internal radius equal to or greater than double thickness 1/2 of the thickness.

Can you explain to me what I have to set up on proe because it gives me the same values?

Thank you.

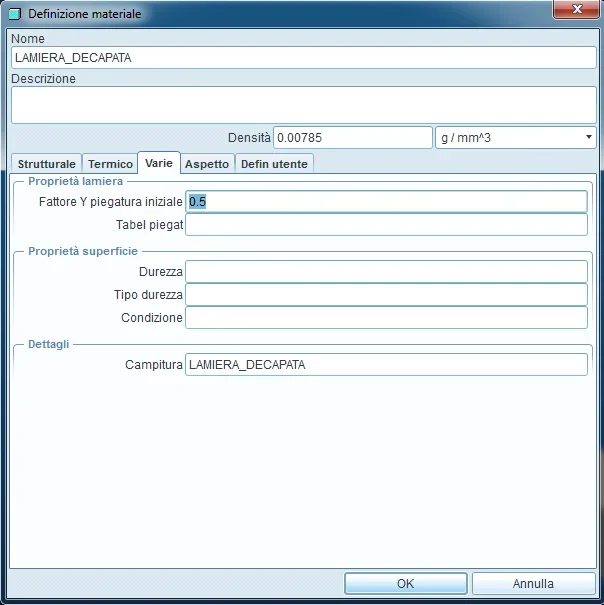

- factor k (depending on thickness)

- sheet metal

- Internal radius

- bending threshold (double thickness)

I did some tests and noticed that:

if I extrude the profile and then the development by inserting the desired k factor the development coincides with that of thinkdesign, if instead I extrude the development and then the piego I find some mm differences on the folds different from 90°.

this is the table for calculating the position of the neutral axis and as a result of the k factor I use for thikdesign:

sheet thickness 0÷2.5 with internal radius equal to thickness --> living edge only on folds of 90° for different angles is considered 1/3 of the psessor.

sheet thickness 3÷6 with internal radius equal to the thickness --> 1/3 of the thickness.

sheet thickness 7÷12 with internal radius equal to thickness --> 0.4 of thickness.

sheet thickness >12 with internal radius equal to thickness --> 0.5 of thickness.

sheet thickness any with internal radius equal to or greater than double thickness 1/2 of the thickness.

Can you explain to me what I have to set up on proe because it gives me the same values?

Thank you.