Alecian!

Guest

Good morning.

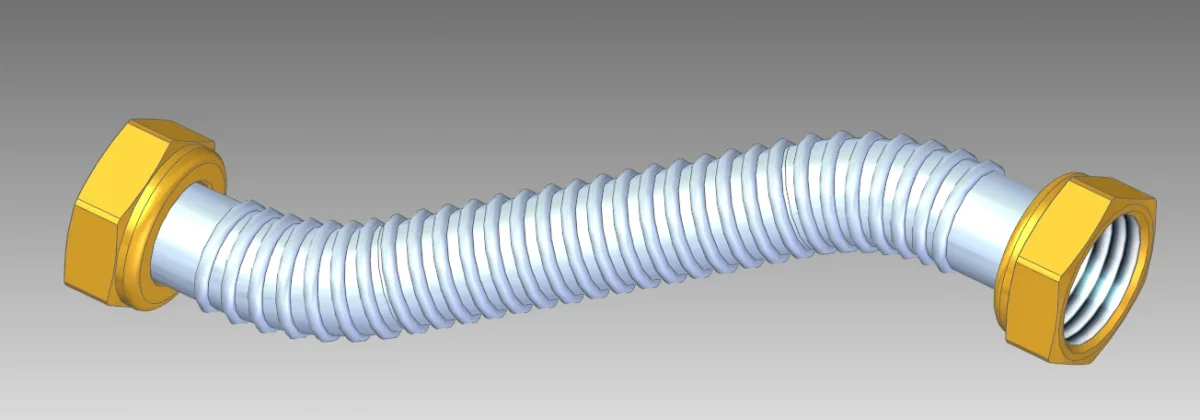

I have to represent in 3d a corrugated tube. after some research I managed to find a good solution:

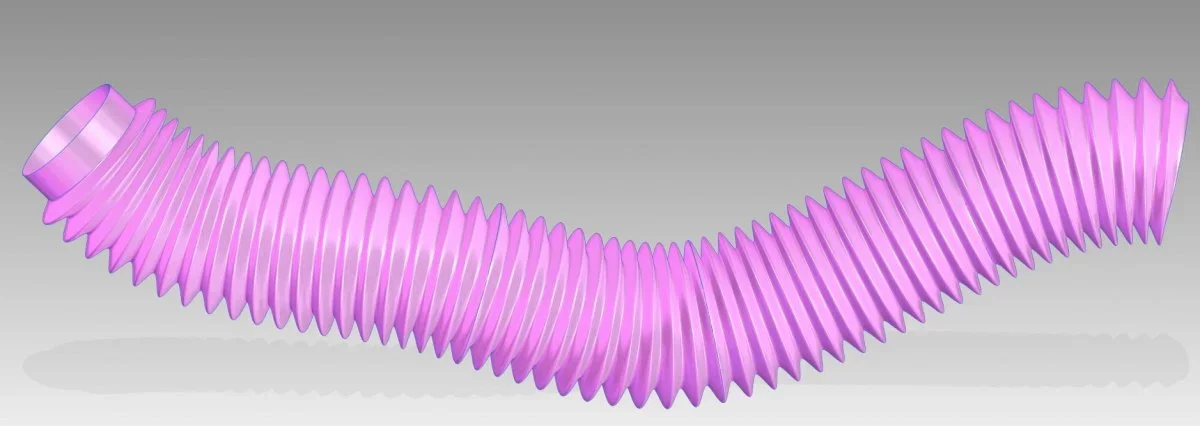

same thing with the command "add thickness".

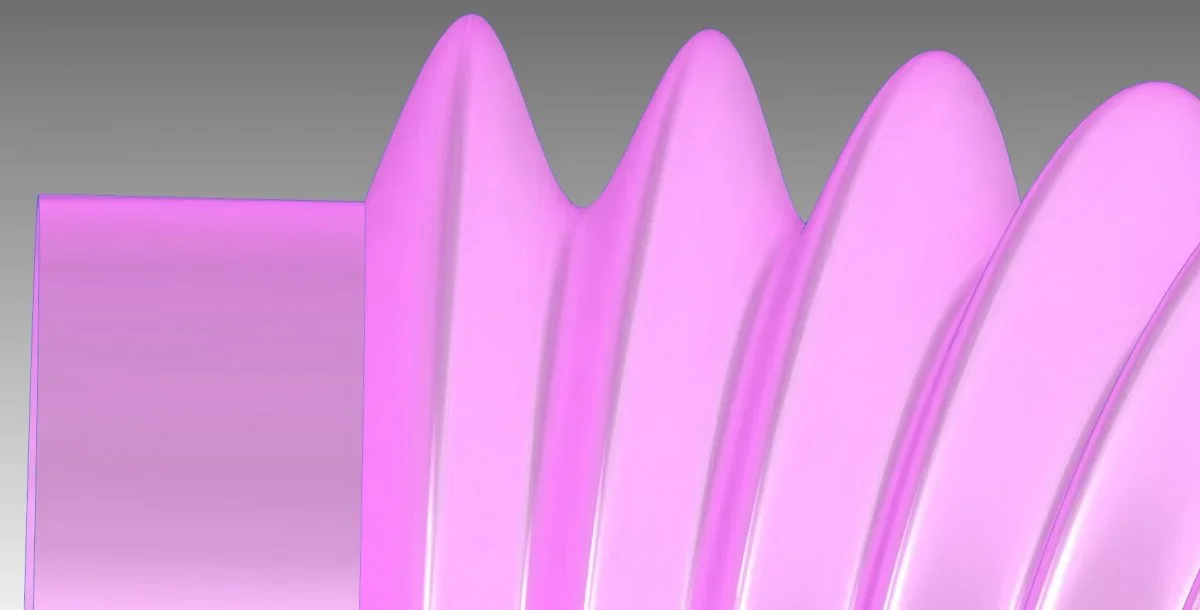

I come to mind while writing that to solve the problem I could build another surface covering the above but with the increased diameters equal to the thickness of the material. I am not convinced, however, as it would be more uncomfortable to change in the future.

Do you have any idea how to end the 3d? or even better, other roads leading to the realization of corrugated tubes that are visible bent or on the floor.

thanks in advance

I have to represent in 3d a corrugated tube. after some research I managed to find a good solution:

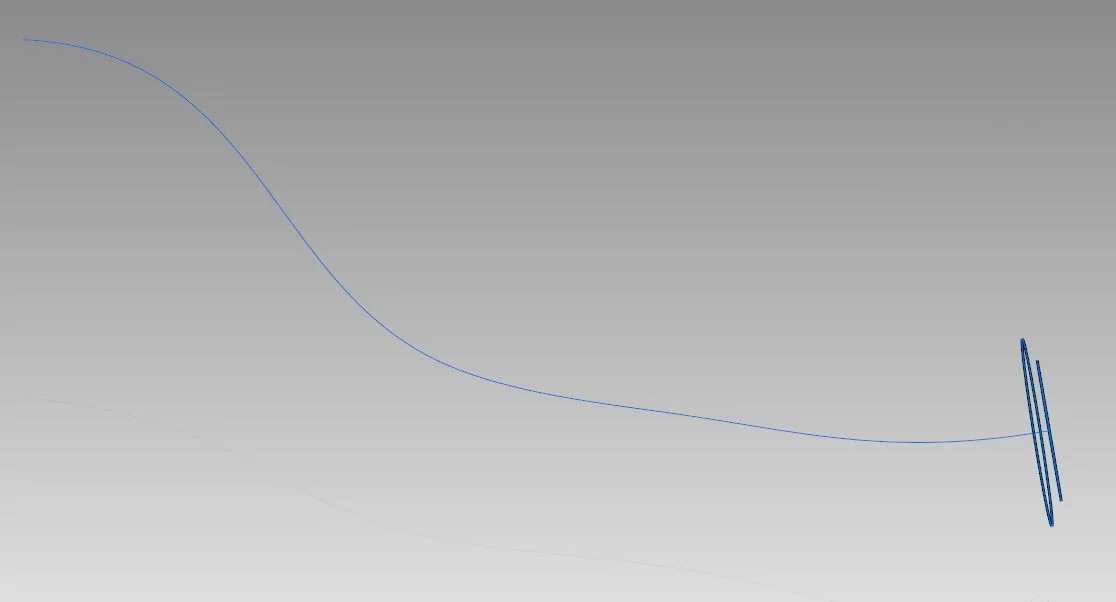

- I started from a path made as 3d sketch or as a curve for points on a single floor.

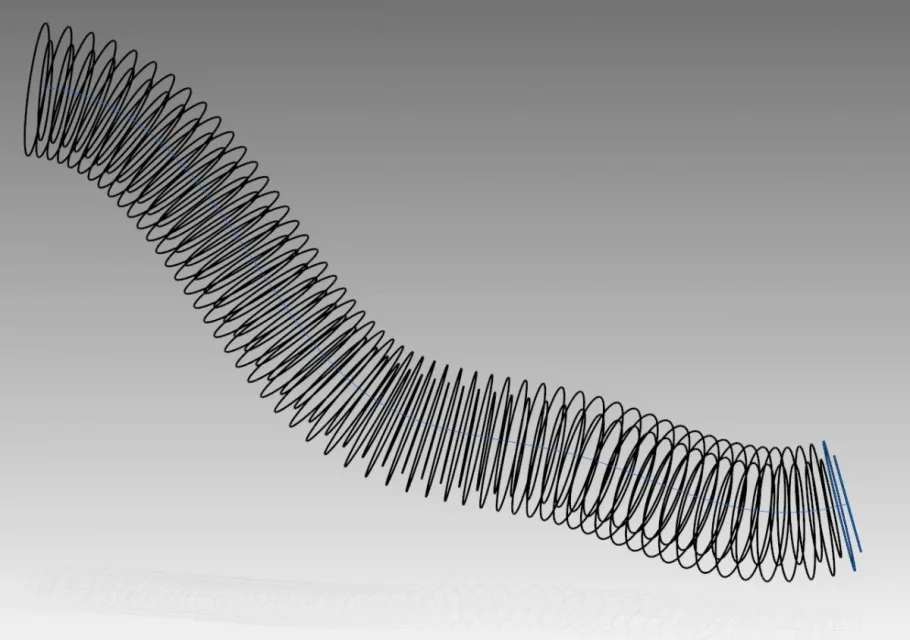

- at its end I performed a normal sketch at the curve to create the first section of the corrugated. 3mm away from this plane I then repeated this last step for the realization of a second section with a larger diameter.

- I created a derived curve by selecting both circumferences.

- I created a sampling along the path through the "long curve" command.

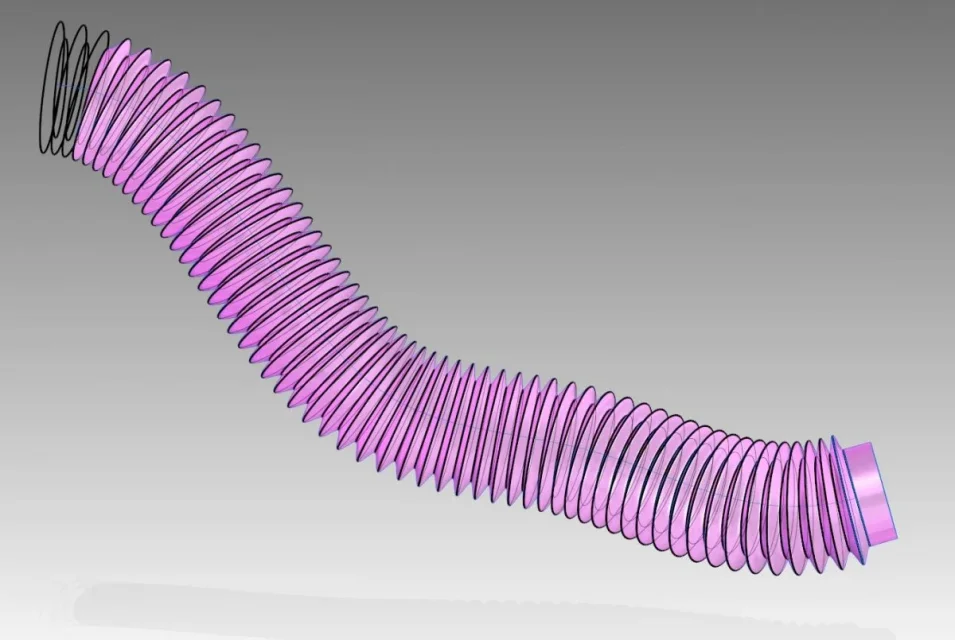

- with the command "bluesurf" I joined the various sections.

same thing with the command "add thickness".

I come to mind while writing that to solve the problem I could build another surface covering the above but with the increased diameters equal to the thickness of the material. I am not convinced, however, as it would be more uncomfortable to change in the future.

Do you have any idea how to end the 3d? or even better, other roads leading to the realization of corrugated tubes that are visible bent or on the floor.

thanks in advance