mrdrum94

Guest

Hello everyone,

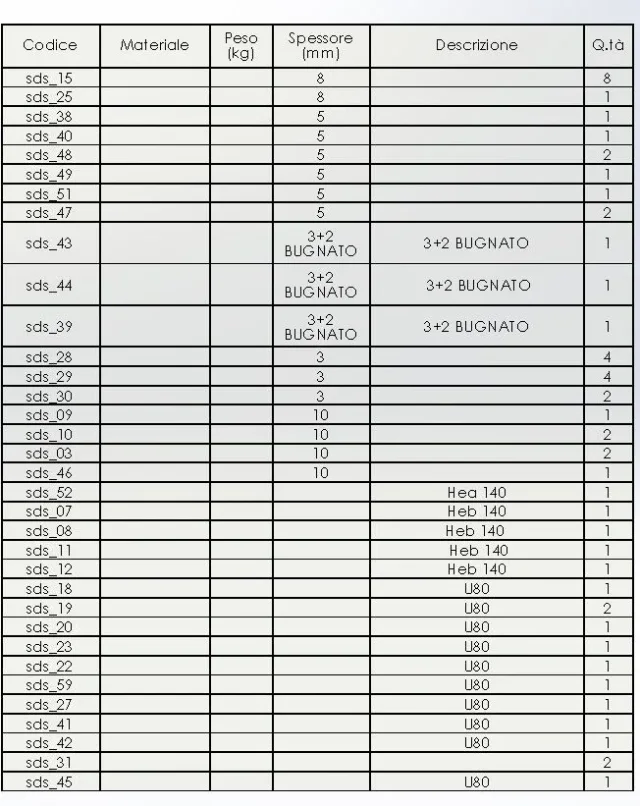

work in a metal carpentry company and it is customary to use assemblies consisting of commercial profiles and molded plate. to date the insertion of the profile description in the separate materials has been manual. I would like to know if there is an automatic way to enter the profile type directly in the table "different materials" without resorting to separate cutting and distinct materials with recesses.

Thank you.

work in a metal carpentry company and it is customary to use assemblies consisting of commercial profiles and molded plate. to date the insertion of the profile description in the separate materials has been manual. I would like to know if there is an automatic way to enter the profile type directly in the table "different materials" without resorting to separate cutting and distinct materials with recesses.

Thank you.