Sisina

Guest

Hello everyone, I just signed up.

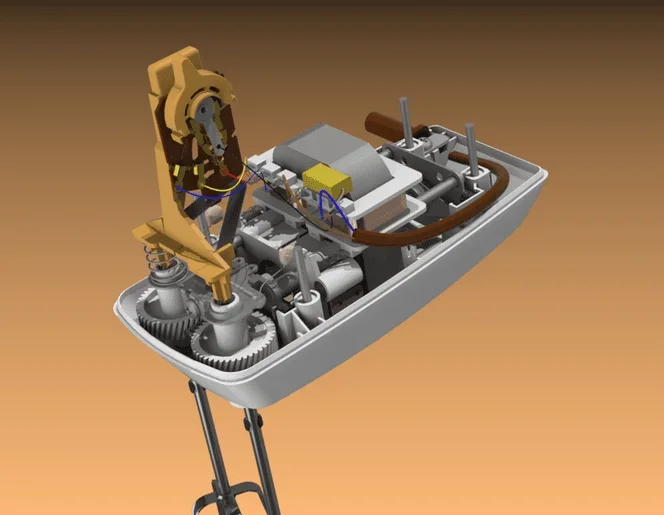

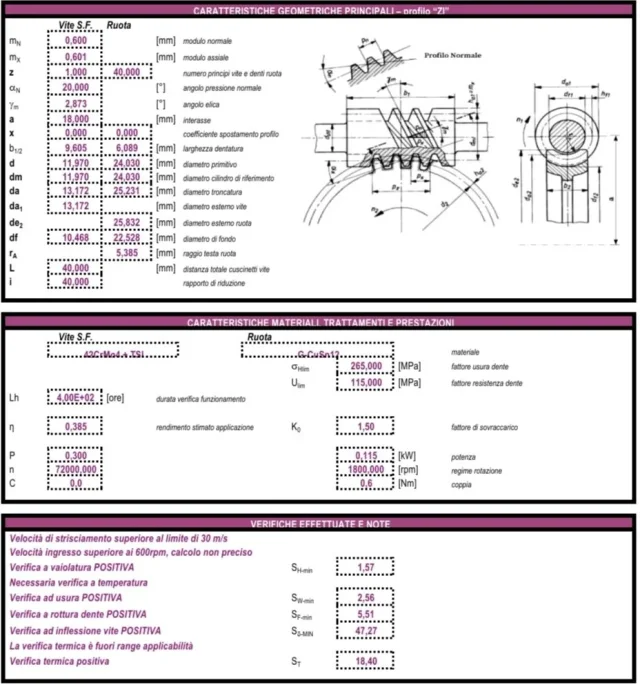

I'm a student at the master of mechanical engineering. I'm designing an electric shocker and I have to do the maximum calculations but I don't know where to start. I chose a brushless motor and a transmission with endless screw and wheel. the only since I have is the speed of the whips then of the wheel that reaches up to 2000 rpm. I have assumed a number of teeth of the wheel of 40 and the number of principles of the screw pairs to 1, through the transmission ratio I found speed of the screw and therefore of the motor of 750o s^-1 = 72000 turns/min. I think it's very big as value because the power of this kind of appliances is about 400w, you think it's okay or I'm wrong somewhere?

while for the design of the endless screw can I proceed as for normal rotisms? that is through a iterative calculation then calculation mt, sigma adm, transversal module with formula of the helical wheels, ray of the screw, peripheral speed of the screw and remake everything until I find values of the module close to the unified one.

I don't know if I've asked too much or different topics? I hope it's okay

I'm a student at the master of mechanical engineering. I'm designing an electric shocker and I have to do the maximum calculations but I don't know where to start. I chose a brushless motor and a transmission with endless screw and wheel. the only since I have is the speed of the whips then of the wheel that reaches up to 2000 rpm. I have assumed a number of teeth of the wheel of 40 and the number of principles of the screw pairs to 1, through the transmission ratio I found speed of the screw and therefore of the motor of 750o s^-1 = 72000 turns/min. I think it's very big as value because the power of this kind of appliances is about 400w, you think it's okay or I'm wrong somewhere?

while for the design of the endless screw can I proceed as for normal rotisms? that is through a iterative calculation then calculation mt, sigma adm, transversal module with formula of the helical wheels, ray of the screw, peripheral speed of the screw and remake everything until I find values of the module close to the unified one.

I don't know if I've asked too much or different topics? I hope it's okay