alessandro0898

Guest

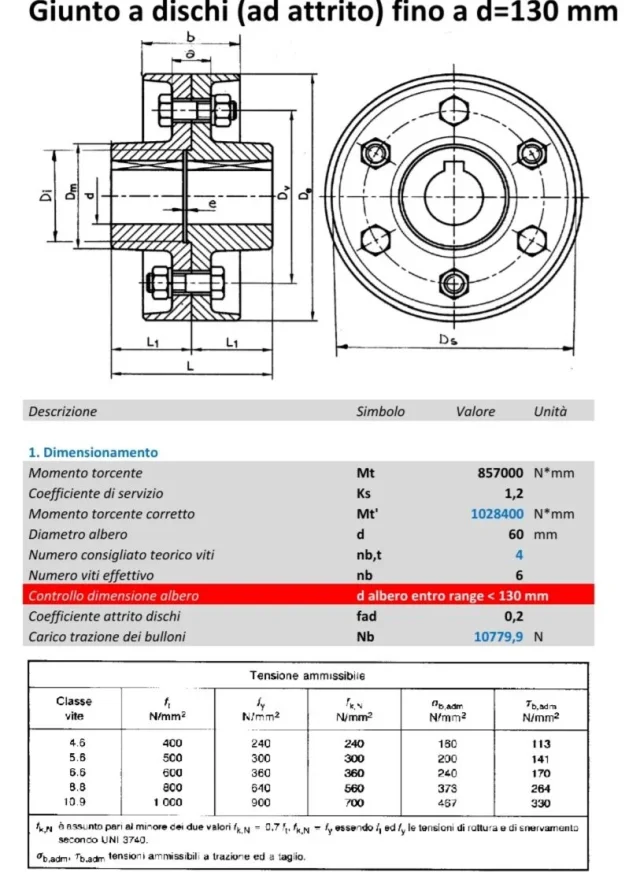

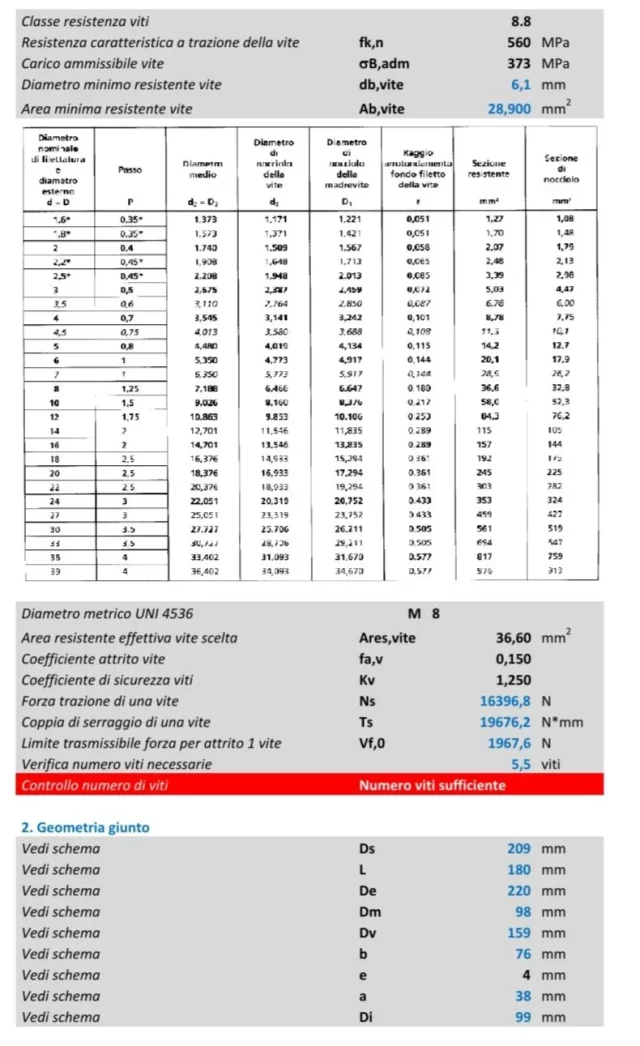

Good evening, I'd need help with a mechanical technology project. In practice I have to design a hard joint with disks, precisely one flange, knowing the power (about 155 kw) that must deliver the motor to which I have to connect it. I assumed an electric motor with two pairs of poles, so that it turns to 1500rpm, do you think it is right as an idea? Second, I had doubts about the material to make the joint by supposing using a c40 steel for the tree. I was undecided between a c45 steel and a stainless steel as they are those I found on the internet. Can you give me more information about this?

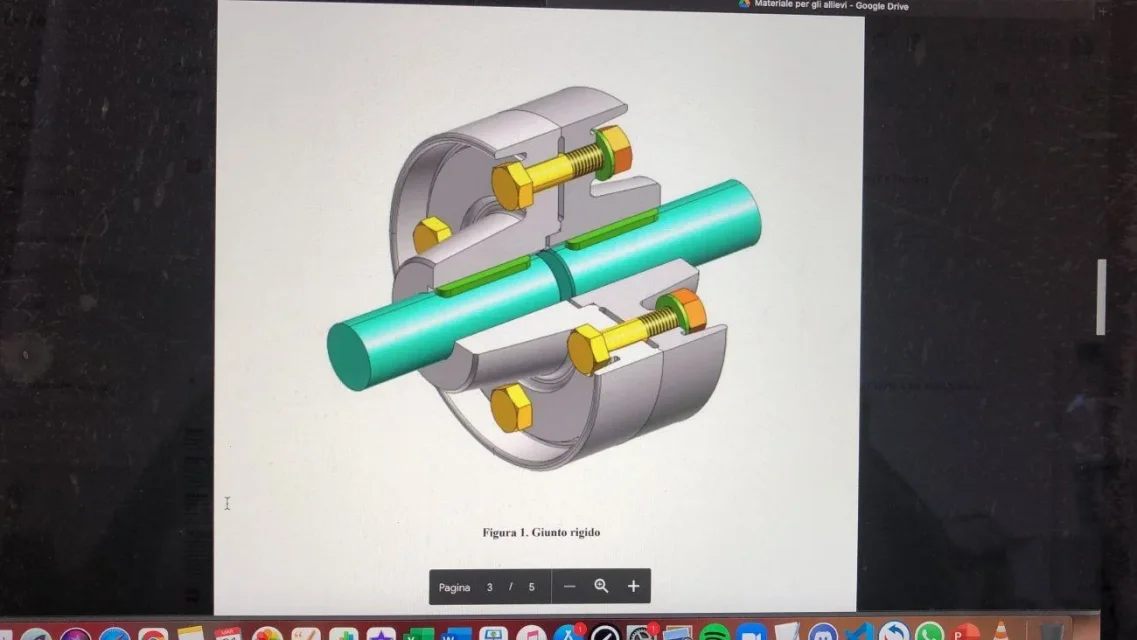

I attach the photo of the joint to be realized

I attach the photo of the joint to be realized