campotino

Guest

Good morning.

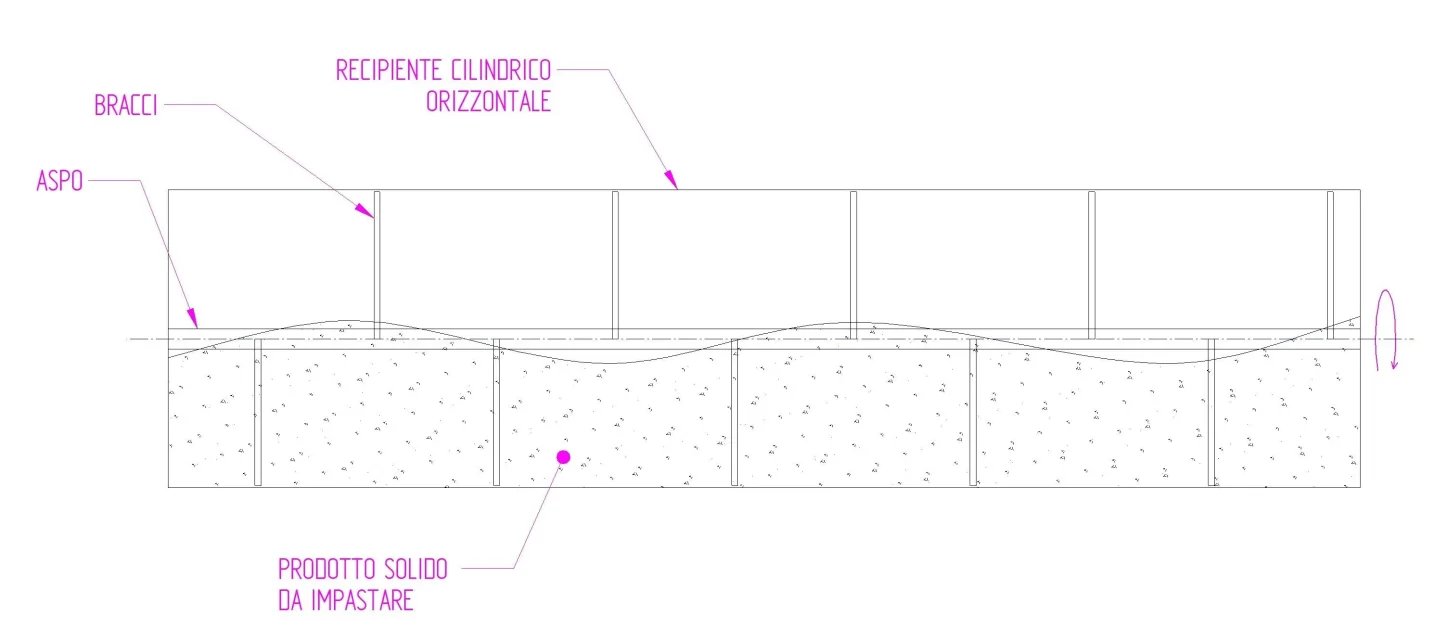

I have a horizontal cylinder with a rotating axle in the center having arms (reds).

the cylinder is filled in half and the aspo must take care of turning the mass.

for a similar problem, is there any example in literature to estimate the necessary torque to rotation?

Thank you.

I have a horizontal cylinder with a rotating axle in the center having arms (reds).

the cylinder is filled in half and the aspo must take care of turning the mass.

for a similar problem, is there any example in literature to estimate the necessary torque to rotation?

Thank you.