DarkAngel

Guest

Hello.

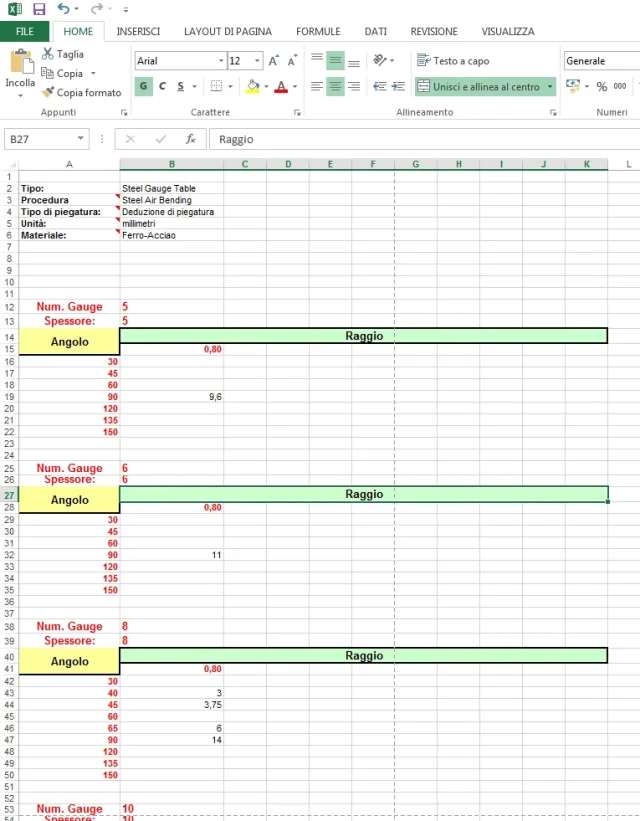

after various tests, measures, etc. I finally settled (for angles of 90°) all the fold tables (with deduction of bd fold) for each quarry.

so I have a folder with inside a file of excel for each folding quarry (10,12,16,20,22,25,35,50,80) repeated to divide the stainless tables from those of iron. all with radius 0.8 fold (I know that the rule is not that... bla bla r= thickness of the material... blah blah) I'm not the boss, we only have knives r=0.8 so we do or nothing, unfortunately)

question 1: Now every time I go to draw a piece that then will have to be folded select the table, the thickness and are in place, there is way to join the tables in a single file (or even 2, 1 for stainless steel and one for iron) so that from the model takes automatically material and thickness and I just have to decide the quarry?

question 2: Importing customer steps always happens that the fold radius is equal to the thickness, and solidworks warns me that it is not possible to change the radius of pre-built folds. so to overcome the problem I added various rays to the tables (0.5, 1, 2, 3, 4... etc.) all with the same bd factor; so even if the step file has different rays the development is always right according to the caves and knives we have., the problem arises when in the same step there are folds with different rays and for the radius that select I calculate the correct development, while for the folds that have a different radius apply the k factor and therefore wrong the development, even if the radius is present in the table. Is there any way to overcome this?

question 3: The calculation with the bending deduction does not develop the "piega and crush" how do I make him take a value that I decide?

Obviously I write here because after having called for 4 times the assistance (newmacut in case you were interested) the answers varied from: "I don't know" to "bhe obviously do not work well the tables, different factuals, arranged"

after various tests, measures, etc. I finally settled (for angles of 90°) all the fold tables (with deduction of bd fold) for each quarry.

so I have a folder with inside a file of excel for each folding quarry (10,12,16,20,22,25,35,50,80) repeated to divide the stainless tables from those of iron. all with radius 0.8 fold (I know that the rule is not that... bla bla r= thickness of the material... blah blah) I'm not the boss, we only have knives r=0.8 so we do or nothing, unfortunately)

question 1: Now every time I go to draw a piece that then will have to be folded select the table, the thickness and are in place, there is way to join the tables in a single file (or even 2, 1 for stainless steel and one for iron) so that from the model takes automatically material and thickness and I just have to decide the quarry?

question 2: Importing customer steps always happens that the fold radius is equal to the thickness, and solidworks warns me that it is not possible to change the radius of pre-built folds. so to overcome the problem I added various rays to the tables (0.5, 1, 2, 3, 4... etc.) all with the same bd factor; so even if the step file has different rays the development is always right according to the caves and knives we have., the problem arises when in the same step there are folds with different rays and for the radius that select I calculate the correct development, while for the folds that have a different radius apply the k factor and therefore wrong the development, even if the radius is present in the table. Is there any way to overcome this?

question 3: The calculation with the bending deduction does not develop the "piega and crush" how do I make him take a value that I decide?

Obviously I write here because after having called for 4 times the assistance (newmacut in case you were interested) the answers varied from: "I don't know" to "bhe obviously do not work well the tables, different factuals, arranged"