egdo

Guest

Bye.

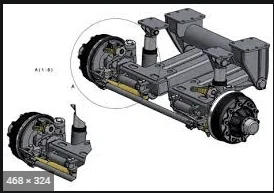

I wanted to ask for an opinion on hydraulic suspensions mounted on work machines such as semovent or tractor mixers.

according to you what is the best position of the cylinder for there front suspension? with stem at the bottom or at the top? and possibly for the back one.

I look forward to some advice on how they are correct according to you.

Thank you.

I wanted to ask for an opinion on hydraulic suspensions mounted on work machines such as semovent or tractor mixers.

according to you what is the best position of the cylinder for there front suspension? with stem at the bottom or at the top? and possibly for the back one.

I look forward to some advice on how they are correct according to you.

Thank you.