Matteo.R

Guest

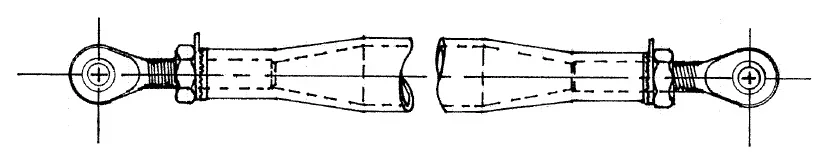

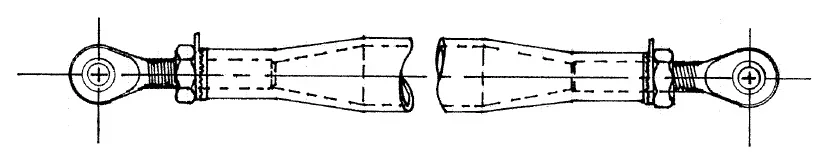

Good morning to all, this is my first discussion, I am a master student of aeronautical engineering and I would have a doubt regarding the design of an auction that I have to do for a school project. the rod in question is an aviation duty rod and is loaded with normal effort. to the extremes two terminals with male thread whose nominal diameter is known, as in the exemplifying figure that I attach: my question is: how to proceed in the check on the cross section of the auction that houses the terminal?

my question is: how to proceed in the check on the cross section of the auction that houses the terminal?

if you would like to check a generic central section (where the rod is not threaded, by the way) I would write:

♪[ \frac{N_Z}{A}\leq\ \frac{S_y}{CS} \]where nz is the normal effort acting on the auction, \[ A=\pi \frac{D_1^2-d_1^2}{4} \] is the area of the section (d1,d1 are the external and internal diameters), sy is the yielding voltage of the material and cs is the safety coefficient used. regarding a section in which the internal thread for the housing of the terminal is present, how can I proceed?

my question is: how to proceed in the check on the cross section of the auction that houses the terminal?

my question is: how to proceed in the check on the cross section of the auction that houses the terminal?if you would like to check a generic central section (where the rod is not threaded, by the way) I would write:

♪[ \frac{N_Z}{A}\leq\ \frac{S_y}{CS} \]where nz is the normal effort acting on the auction, \[ A=\pi \frac{D_1^2-d_1^2}{4} \] is the area of the section (d1,d1 are the external and internal diameters), sy is the yielding voltage of the material and cs is the safety coefficient used. regarding a section in which the internal thread for the housing of the terminal is present, how can I proceed?