Osammot

Guest

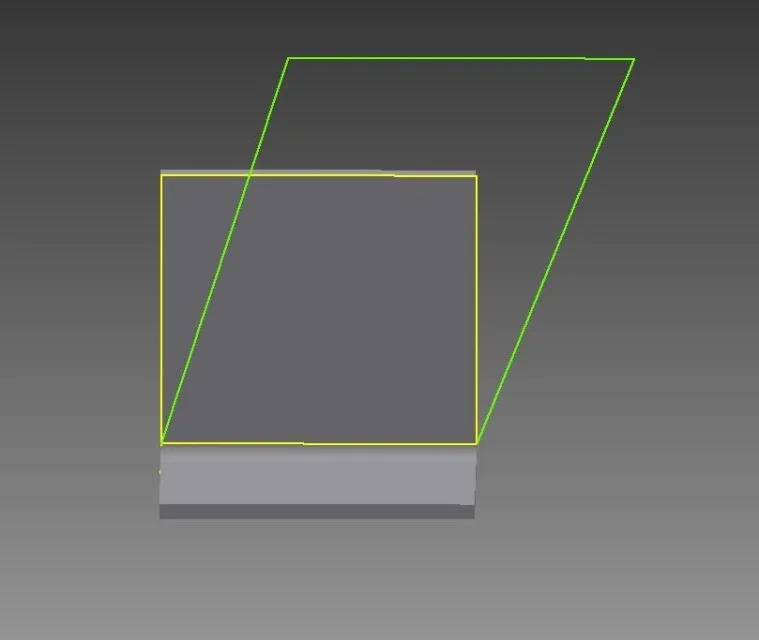

Greetings to all. These days I have seen the sheet environment of the inventor program. Having arrived at the fold command (fold) I got a question.

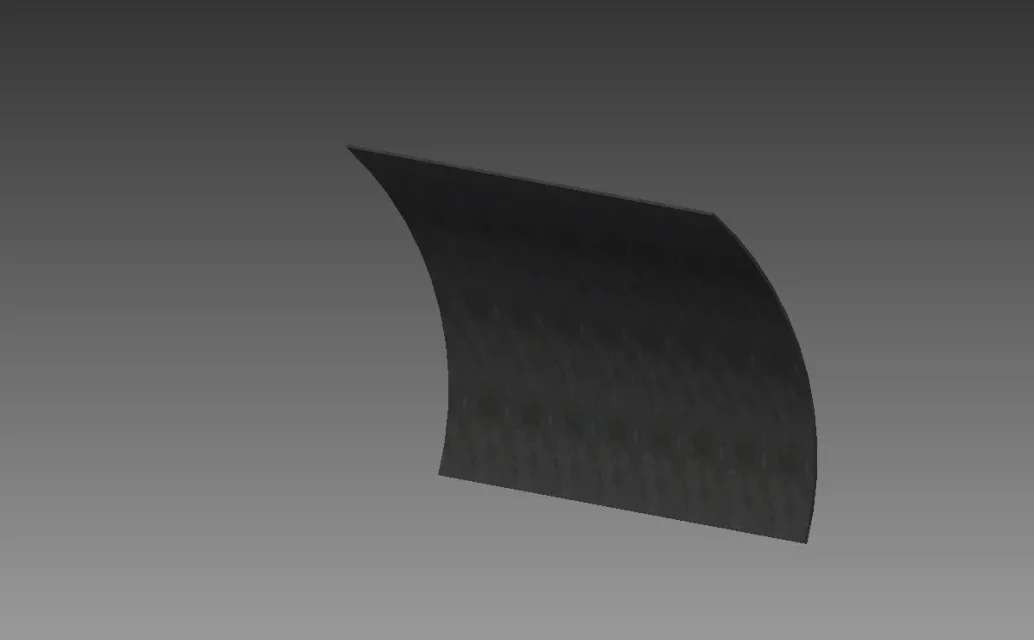

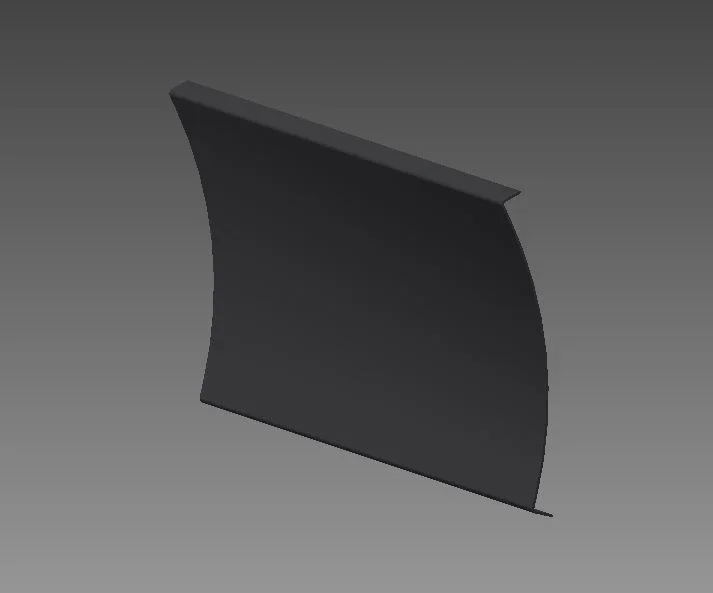

why starting from a normal sketch rectangle and adding folds along sketch lines the piece is not adapted to the size that should have adding folds? in practice, at the end when I use the command "go on a flat model" simply extends the piece, but it is as long as the initial sketch (does not take into account the added folds). is not really developed.

with the command "flangia", instead I can get the same piece (with the same folds) with the real development. because with the command "piega (fold)" does not happen the same thing?

I imagine they have different purposes that I still have not deepened, but if I add folds (in one way or another) the piece should not have the initial dimensions anymore. I imagine, however, that the programme does not become an autonomous change in the size of the initial sketch. how can you then have the real development of the piece using the command "piega (fold)" and not "flangia"?

Thank you.

why starting from a normal sketch rectangle and adding folds along sketch lines the piece is not adapted to the size that should have adding folds? in practice, at the end when I use the command "go on a flat model" simply extends the piece, but it is as long as the initial sketch (does not take into account the added folds). is not really developed.

with the command "flangia", instead I can get the same piece (with the same folds) with the real development. because with the command "piega (fold)" does not happen the same thing?

I imagine they have different purposes that I still have not deepened, but if I add folds (in one way or another) the piece should not have the initial dimensions anymore. I imagine, however, that the programme does not become an autonomous change in the size of the initial sketch. how can you then have the real development of the piece using the command "piega (fold)" and not "flangia"?

Thank you.