abj79

Guest

Good morning to all,

This is my first post! I have problems interpreting a design about the presence of tolerance on both line and surface profiles.

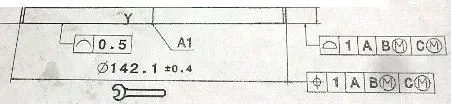

I have a design of a hollow tube (rect cylinder) rested on the floor for the basic circumference. on the line that defines the circumference in the side prospectus (the side prospect of a cylinder is a rectangle, so the basic circumference is the lower side of this rectangle, measure: φ142.0+/-0.4mm) I simultaneously have the tolerance on the line profile (0.5mm) and the surface profile (0.8mm). who helps me understand how to interpret them and how to measure this piece? Why is one of the two indications of tolerance not enough? Thank you all, hello!

This is my first post! I have problems interpreting a design about the presence of tolerance on both line and surface profiles.

I have a design of a hollow tube (rect cylinder) rested on the floor for the basic circumference. on the line that defines the circumference in the side prospectus (the side prospect of a cylinder is a rectangle, so the basic circumference is the lower side of this rectangle, measure: φ142.0+/-0.4mm) I simultaneously have the tolerance on the line profile (0.5mm) and the surface profile (0.8mm). who helps me understand how to interpret them and how to measure this piece? Why is one of the two indications of tolerance not enough? Thank you all, hello!