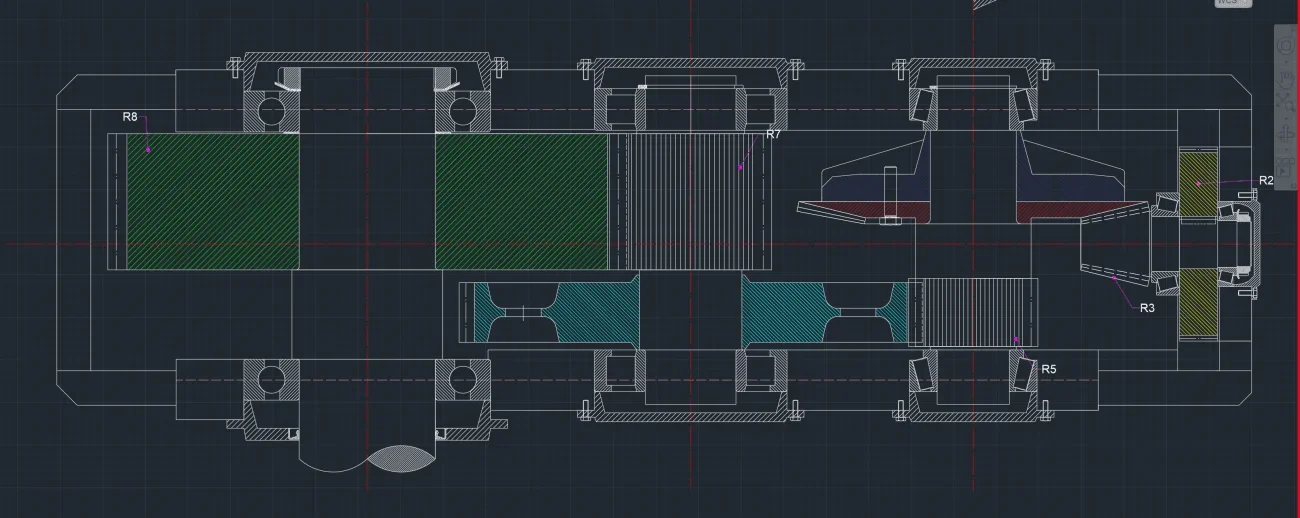

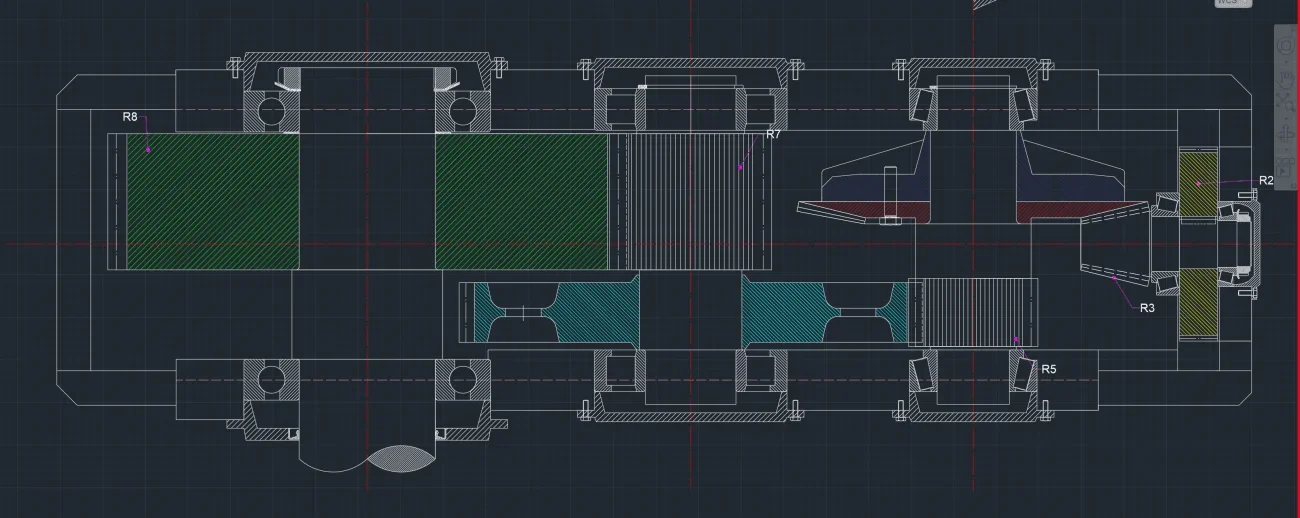

I have the impression that they lack sampling; It is not clear where the carcass of the reducer ends and where there is the vacuum. it is difficult to understand the installation.

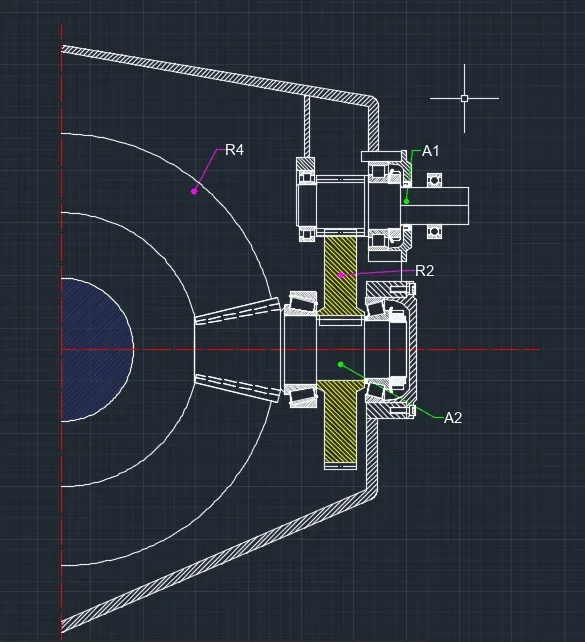

I would also remove the teeth of the central and right gears that weigh the design, do not serve anything and make the transmission uncomplicated; to have a common language I would point out the main elements, as you really do in drawings, discussion (shaft a, bearing a1 and a2...) so as to avoid long descriptions to indicate what you are talking about (the upper bearing of the tree to the left = a2).

various comments:

fange does not need to do inclined internal digging while also reducing contact with the outer ring of bearings. look in the manuals of the skf the minimum and maximum size of support.

left tree lacking lines on the definition of the wreath

left shaft the diameter of the wheel should have a diameter greater than that of the bearing for not having to mount to interference a section not necessary

lower shaft flange on the left, the seal is not blocked

lower central shaft wheel can move upward