petrelli9

Guest

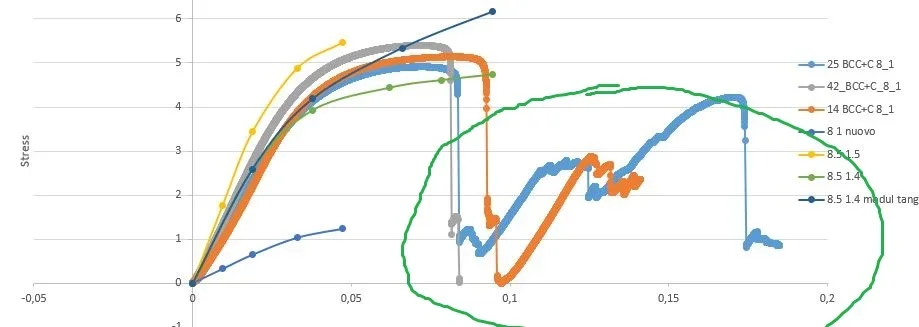

Hello, guys, would anyone tell me how to make ansys the phenomenon of "densification"? in practice it is a test in "lattice" structure subjected to a simple compression test. I managed to get to the plastic section (dark blue curve), but I can't make the piece "break" and then have a trend like what I looked for in green in the image. advice?