antonio s

Guest

Hello.

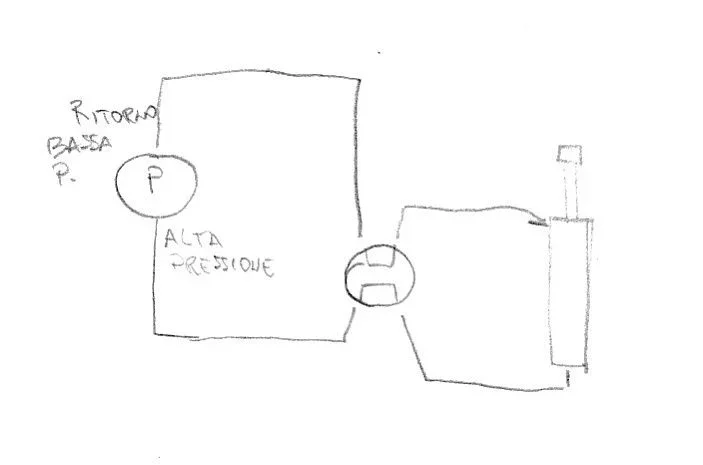

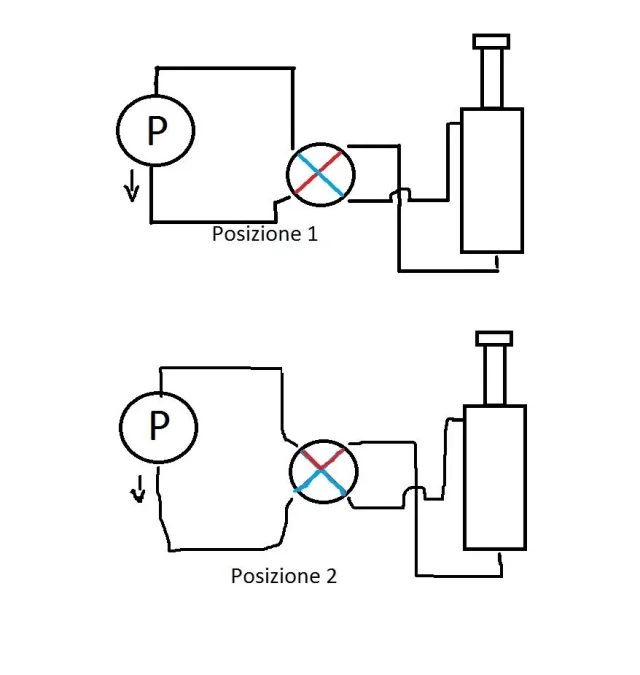

I'm new and I'm looking for someone who understands dynamic oleum to ask for information, I have a hydraulic piston, which was loaded with oil and nitrogen at about 70bar.

Now it is unloaded, so the idea is to repeat what others have done, i.e., connect a hydroguided pump of car and inject pressure oil to raise the stem, the plunger, then reverse the polarity of the hydroguide pump to bring down the stem.

I hope I could explain.

Don't massacre me, please, but if you please explain to me whether it's feasible or not.

I'm new and I'm looking for someone who understands dynamic oleum to ask for information, I have a hydraulic piston, which was loaded with oil and nitrogen at about 70bar.

Now it is unloaded, so the idea is to repeat what others have done, i.e., connect a hydroguided pump of car and inject pressure oil to raise the stem, the plunger, then reverse the polarity of the hydroguide pump to bring down the stem.

I hope I could explain.

Don't massacre me, please, but if you please explain to me whether it's feasible or not.