New Rider

Guest

Good evening,

I've been working on large axioms lately, or rather assimilate with different components installed.

I would like to know if there are tricks/consistencies to create these types of assemblies.

Specifically, to better understand, you have to make a machine long hypothetically 10 meters. these 10 meters of automation divided them by type of processing (e.g. material input, processing 1 , processing 2, processing 3 and finally expulsion of the piece ).

instinctively I will create many assemblies " macro " how many processing (in the case just described are 5 ) that my stain will have to go to perform. of course every " macro" assembly will have all the necessary components for its "mansion". I wanted to understand how to proceed. Is it better to work by inserting in the macro each part or I should be able to escape even more by inserting in the "macro" set of the sub-axis?

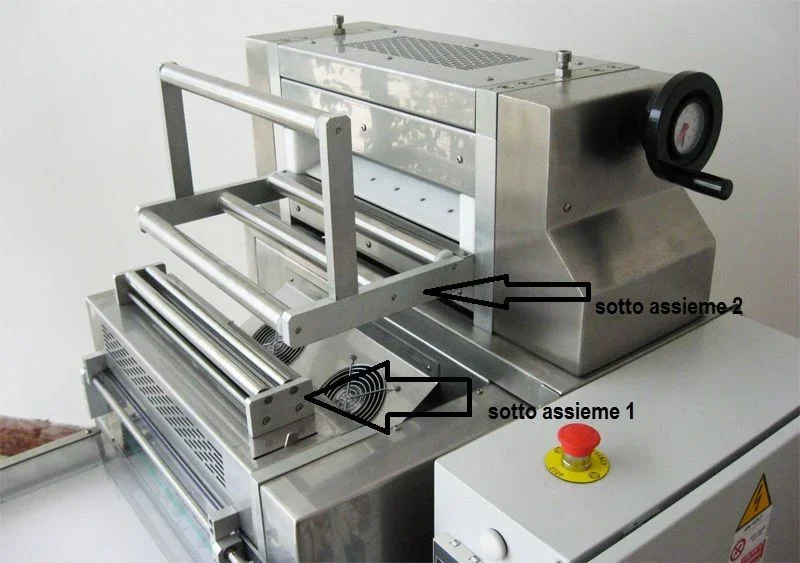

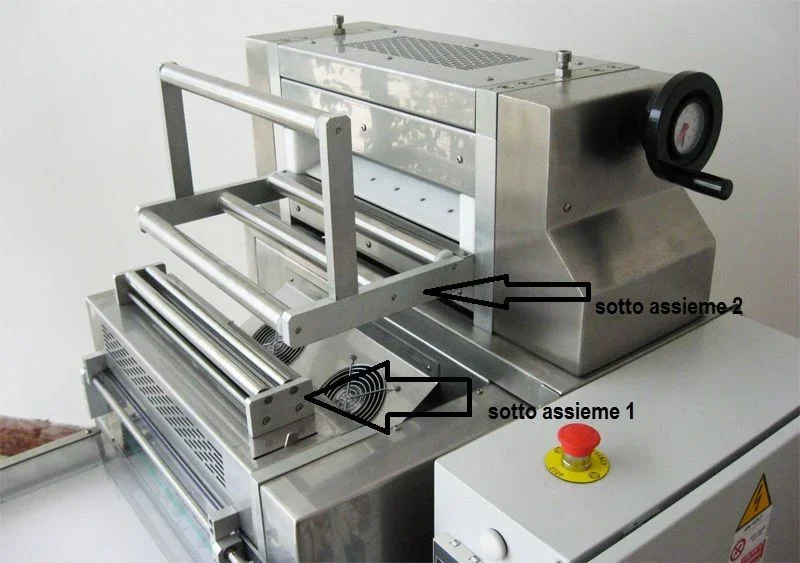

example as from photo attached : I have all this machine that will be connected to another machine for continuous machining of the piece. to divide (as already explained before.. ) I will create macro assemblies.

I have all this machine that will be connected to another machine for continuous machining of the piece. to divide (as already explained before.. ) I will create macro assemblies.

to create axiemi macro it is better to insert, I repeat every single part (rolls,cuscinetti,segger,viteria etc.) or to create sub assemblies also of some components as pictured? what advantages/disadvantages would bring me this type of work?

I hope I've been clear.

cordially.

I've been working on large axioms lately, or rather assimilate with different components installed.

I would like to know if there are tricks/consistencies to create these types of assemblies.

Specifically, to better understand, you have to make a machine long hypothetically 10 meters. these 10 meters of automation divided them by type of processing (e.g. material input, processing 1 , processing 2, processing 3 and finally expulsion of the piece ).

instinctively I will create many assemblies " macro " how many processing (in the case just described are 5 ) that my stain will have to go to perform. of course every " macro" assembly will have all the necessary components for its "mansion". I wanted to understand how to proceed. Is it better to work by inserting in the macro each part or I should be able to escape even more by inserting in the "macro" set of the sub-axis?

example as from photo attached :

I have all this machine that will be connected to another machine for continuous machining of the piece. to divide (as already explained before.. ) I will create macro assemblies.

I have all this machine that will be connected to another machine for continuous machining of the piece. to divide (as already explained before.. ) I will create macro assemblies.to create axiemi macro it is better to insert, I repeat every single part (rolls,cuscinetti,segger,viteria etc.) or to create sub assemblies also of some components as pictured? what advantages/disadvantages would bring me this type of work?

I hope I've been clear.

cordially.