Disegni Costruttivi

Guest

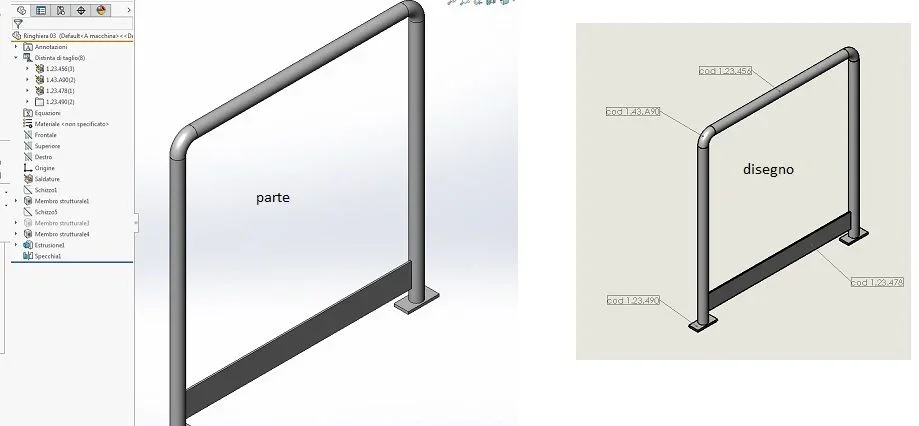

Hello, use tekla structures for 7 years. I would like to ask what is the production process of programs similar to solidworks?

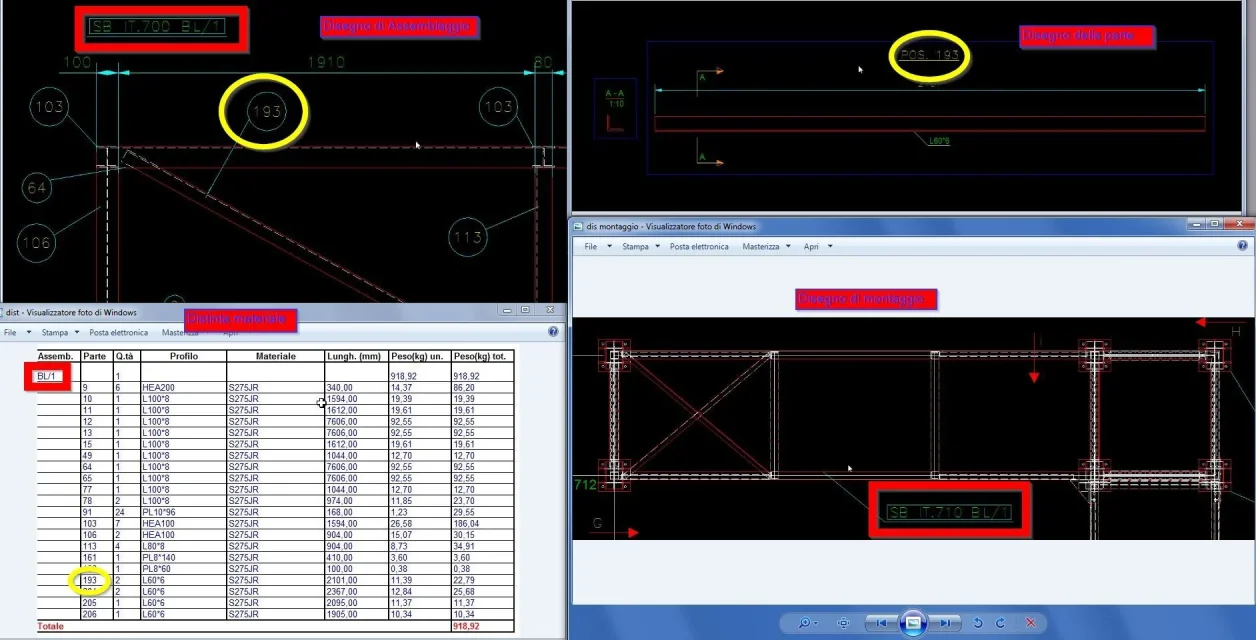

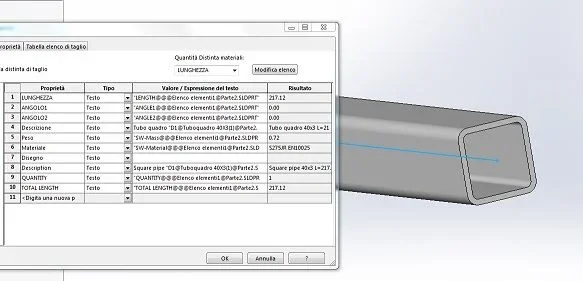

I understand better, I know that with tekla its production process is: modeling of the whole structure, marking, development of drawings of the individual parts, drawings of the welded assemblies, drawings of assembly, drawings of parts with brands and weights both of the parts and of the bolts, supplying files for numerical control machines. I am passionate about tools such as solidworks, but I can't understand its production process, that is, after modeling how I can give the customer that material that allows the final operator to build the molded pieces, I speak drawings of single parts, distinct, etc. I don't think it is able to do it, maybe it exports files that can be inserted into numerical control machines? So I wonder from the model how can I create what I modeled? Thank you.

I understand better, I know that with tekla its production process is: modeling of the whole structure, marking, development of drawings of the individual parts, drawings of the welded assemblies, drawings of assembly, drawings of parts with brands and weights both of the parts and of the bolts, supplying files for numerical control machines. I am passionate about tools such as solidworks, but I can't understand its production process, that is, after modeling how I can give the customer that material that allows the final operator to build the molded pieces, I speak drawings of single parts, distinct, etc. I don't think it is able to do it, maybe it exports files that can be inserted into numerical control machines? So I wonder from the model how can I create what I modeled? Thank you.