crozza

Guest

Hello

I would like to expose you a doubt/problem

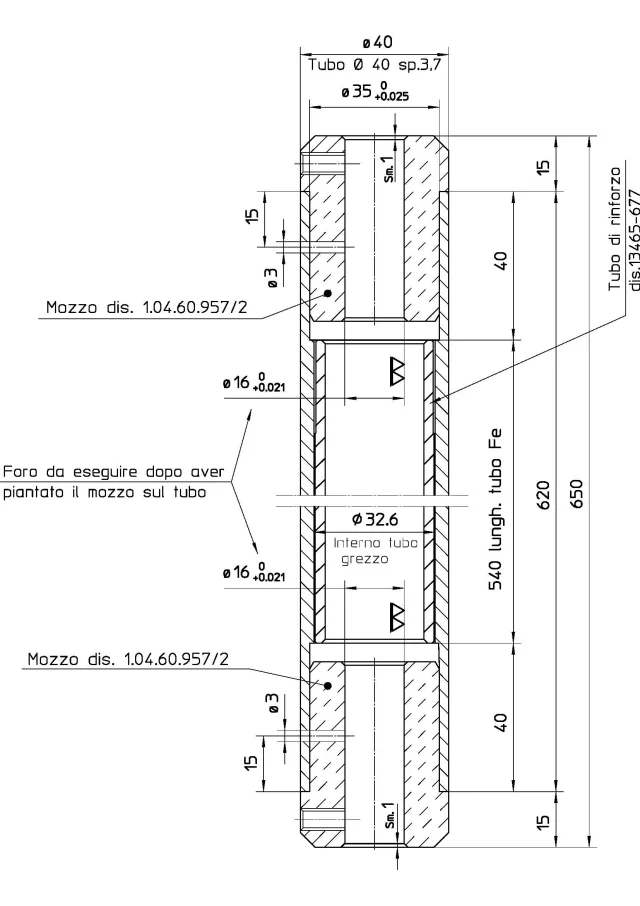

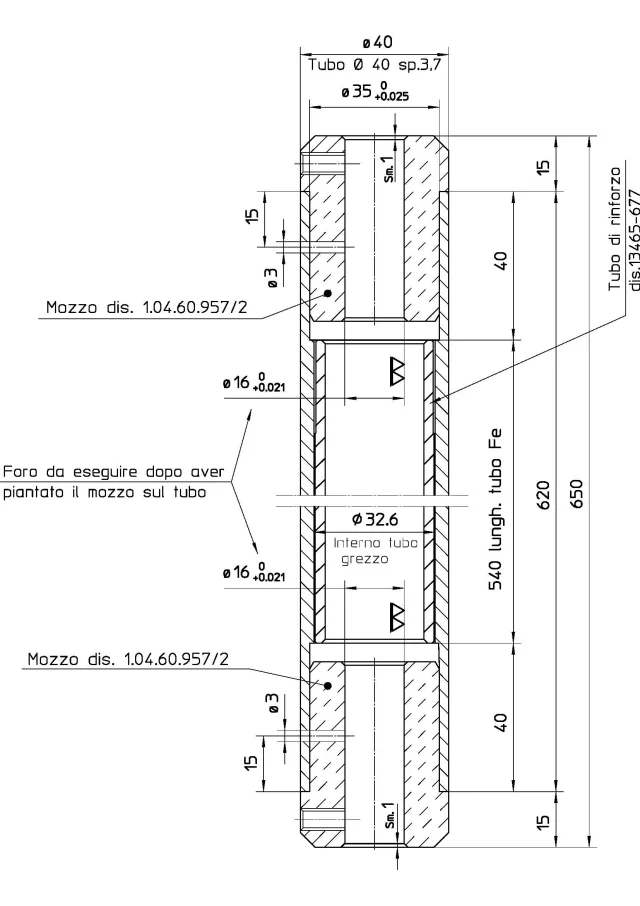

I have a roller made up of a metal core and a plastic sleeve:

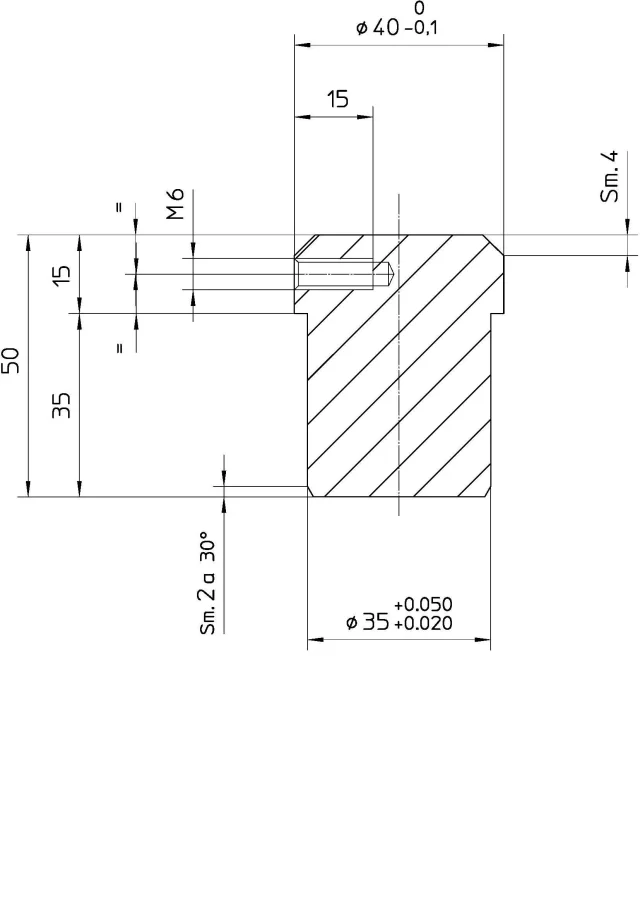

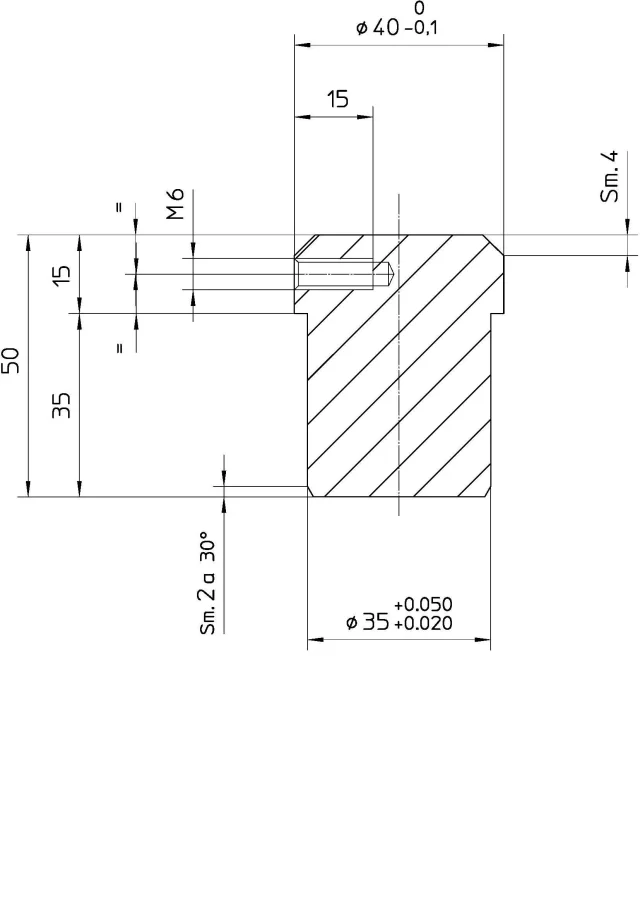

the sleeve consists of two hubs, a metallic reinforcement and a plastic sleeve/tube

the hubs have a pre-finition (dis. 1.04.60.957/2) and after they are assembled they will be subjected to other processing (s. 1.34.65.602)

How do you manage this situation?

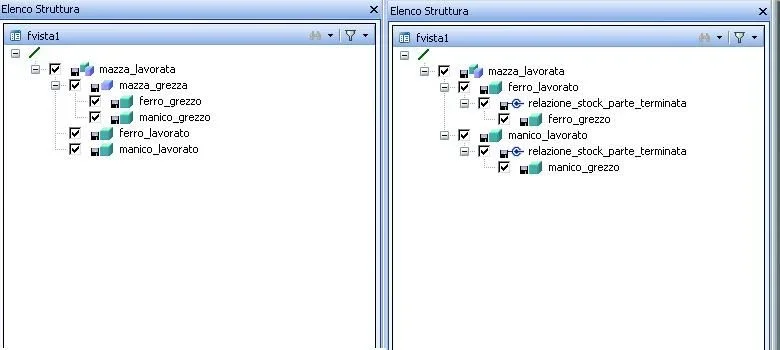

Is there a way to give the same design/code two different "views"? I better explain, that I can choose whether to see it worked or raw, and when I put it on the table I can choose whether to put it raw or worked (as I did in the 2d drafting)

I now create the particular so:

together called a composed of:

soul (not designed in examples) bplastic handle c composed of: worked hubs d + metal reinforcement e + tube fbut the hub will exist also not worked called gBut d e g They will never be bound together.

I hope I explained.

I would like to expose you a doubt/problem

I have a roller made up of a metal core and a plastic sleeve:

the sleeve consists of two hubs, a metallic reinforcement and a plastic sleeve/tube

the hubs have a pre-finition (dis. 1.04.60.957/2) and after they are assembled they will be subjected to other processing (s. 1.34.65.602)

How do you manage this situation?

Is there a way to give the same design/code two different "views"? I better explain, that I can choose whether to see it worked or raw, and when I put it on the table I can choose whether to put it raw or worked (as I did in the 2d drafting)

I now create the particular so:

together called a composed of:

soul (not designed in examples) bplastic handle c composed of: worked hubs d + metal reinforcement e + tube fbut the hub will exist also not worked called gBut d e g They will never be bound together.

I hope I explained.