giusy_v

Guest

Good morning, everyone, I'm jusy and I have a little problem and I hope you can help me.

for a few years I have dealt with chains of tolerances, receiving the necessary inputs to execute the calculation.

Now I'd like to try to set geometric tolerances, but I'm not sure what I'm doing and I hope I can help.

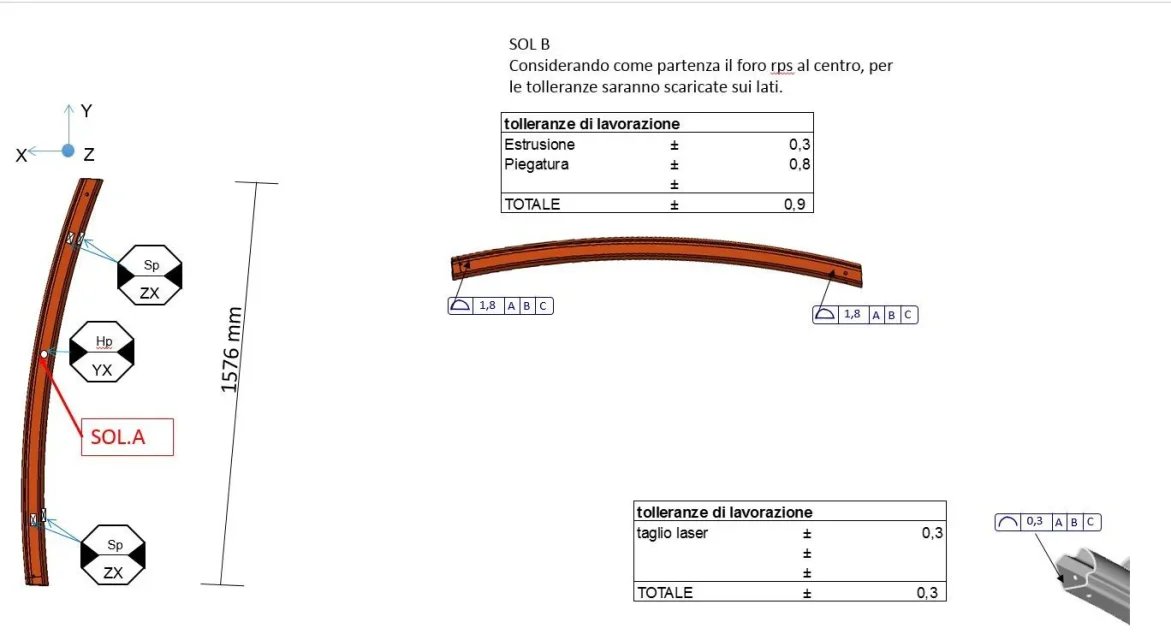

I have a steel tubular as in the attached View attachment estruso.pdf.

I thought about starting from work and considering:

Extrusion

bending

definitive cut

I neglected the others.

the extusion of a steel piece has a tolerance of +/-0.5 each m, but in this way I am not considering dimensional tolerances?

There must be something that escapes me,

thank you for anyone who can help me

Good evening

for a few years I have dealt with chains of tolerances, receiving the necessary inputs to execute the calculation.

Now I'd like to try to set geometric tolerances, but I'm not sure what I'm doing and I hope I can help.

I have a steel tubular as in the attached View attachment estruso.pdf.

I thought about starting from work and considering:

Extrusion

bending

definitive cut

I neglected the others.

the extusion of a steel piece has a tolerance of +/-0.5 each m, but in this way I am not considering dimensional tolerances?

There must be something that escapes me,

thank you for anyone who can help me

Good evening