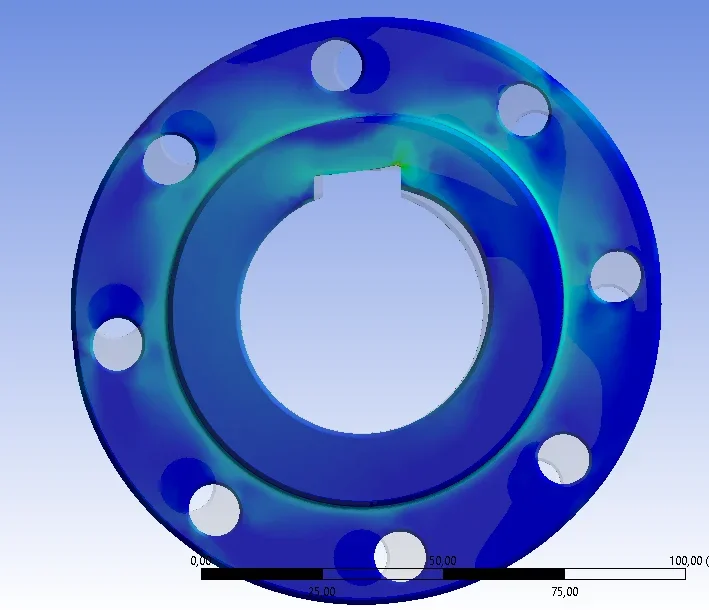

with lower level fem systems, which would not be your case, if you create surfaces around the holes, equal to the size of the washer or the nut of support you can put a force equal to the axial load of the screw itself.

I use solidworks that has all the possibilities of application, including screws etc. But I still put my forces on hand. I often use freecad with calculix, free program with the fem module with few constraints, so you have to act forcefully with the surfaces.

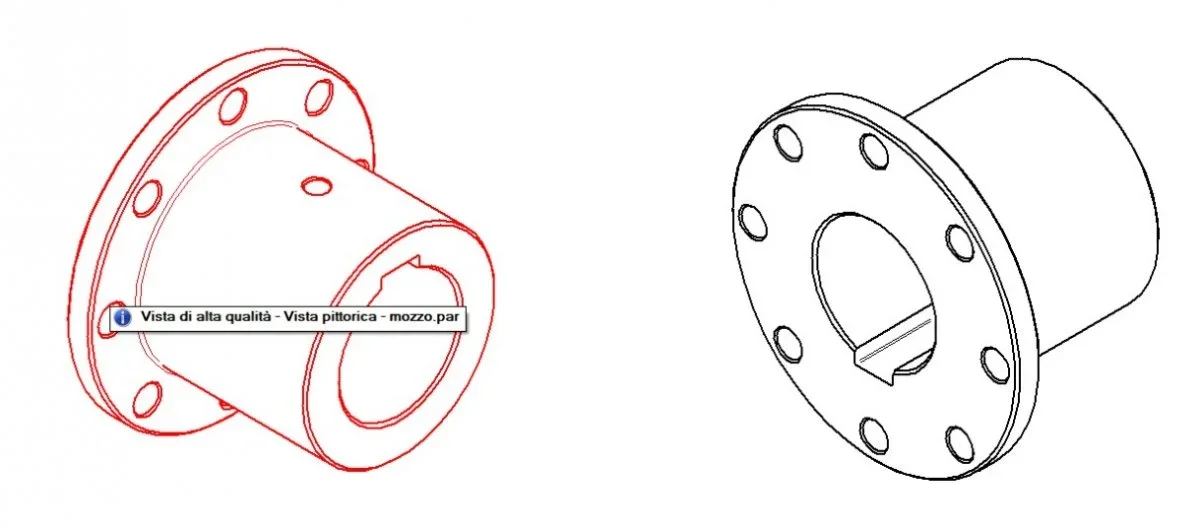

As for constraints, you have to apply a force along the side of the tabbed and a flange bond blocked as a reaction to the generated pair. evaluate whether to react to cut the screws or not.

think about exchange actions and you will see that it is not difficult.