piff91

Guest

Good morning to all,

premise, I am a novello of solidwork but I like the mechanical design and I like to complicate my life. only amateur use.

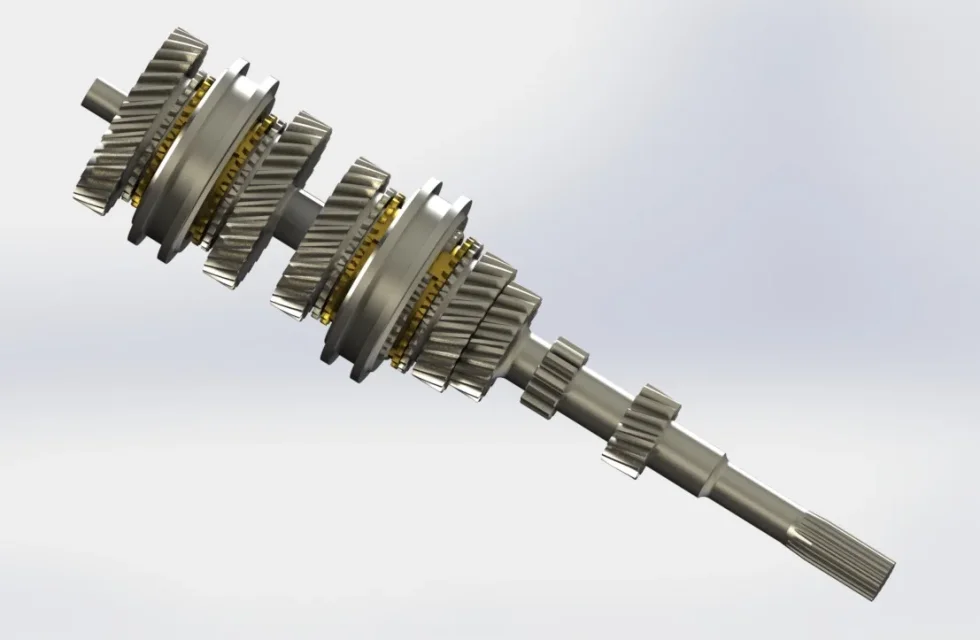

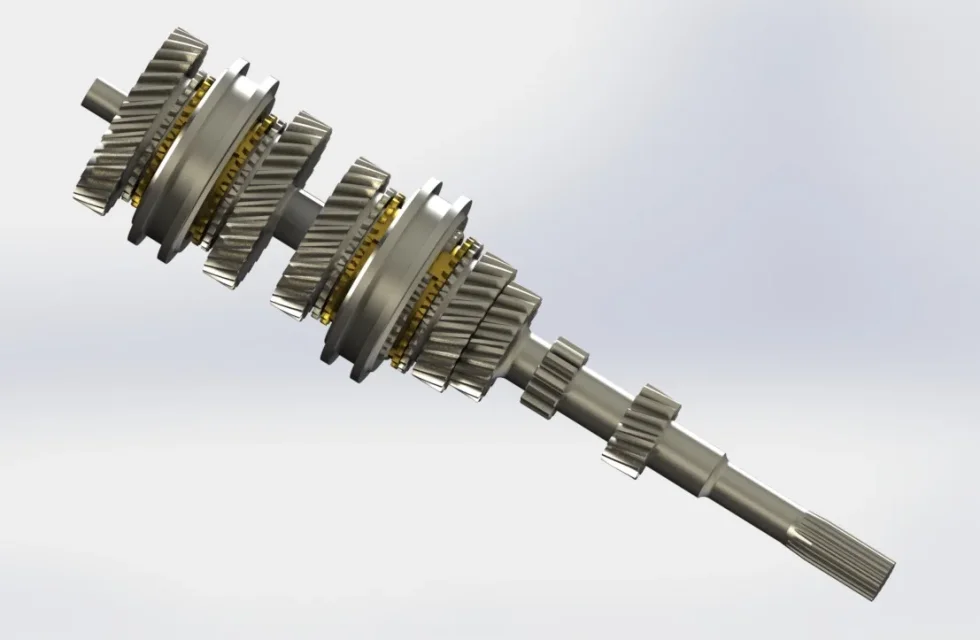

after finding measurements on the internet or measuring some spare parts, I managed to draw the primary tree, the crazy gears, the synchronizers and the sliding sleeve.

my question is how do I couple and make the whole complex functional?

the sliding sleeve moves moving the synchronizing ring that in turn, through conical coupling, goes to brake the crazy gear and then I don't know how, the teeth mate.

solidwork allows you to do this?

I leave some photos/image attached.

I leave some photos/image attached.

premise, I am a novello of solidwork but I like the mechanical design and I like to complicate my life. only amateur use.

after finding measurements on the internet or measuring some spare parts, I managed to draw the primary tree, the crazy gears, the synchronizers and the sliding sleeve.

my question is how do I couple and make the whole complex functional?

the sliding sleeve moves moving the synchronizing ring that in turn, through conical coupling, goes to brake the crazy gear and then I don't know how, the teeth mate.

solidwork allows you to do this?

I leave some photos/image attached.

I leave some photos/image attached.