MF21

Guest

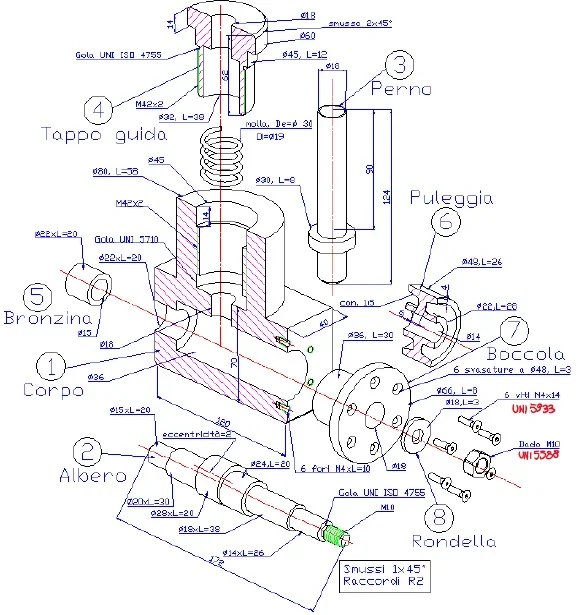

Hi, I'm a spacecraft engineering student and I'm new on the forum. I am preparing the industrial technical drawing exam and if possible I would need help on an exercise, which I attached in the post. Attached I also entered as for now I am carrying out the exercise, performing the first 4 extrapolated pieces. My doubts are as follows:

* in the track of the exercise asks to insert the tolerances in the drawing, but how should these be calculated? a my thought was that, taking for example the connection between the number 1 and the shaft 2, to subtract to the maximum width of the circumference of the piece (diameter 36) to that of the larger cylinder of the shaft (diameter 28 with eccentricity of two) getting a maximum dissection of 2 mm. is it right as reasoning or is it completely wrong as a road?

* in the drawing there are quotations of gorges and threaded pieces. for threaded pieces I found a table on the book which for example, for m42 x 2 tells me that the drilling diameter is 40 mm, but from the theory I know that it is 42 refers to the nominal diameter and 2 the step, what is the measure I have to adopt on the drawing? As for the throat, I did not find any connection to the drawing that helps me find the size of the throat, how should I proceed? also, in the design as listed compartment? with the norm or size in mm?

* the specific track to extract unified details, among these should I draw only pieces ranging from 1 to 8 or even pieces like spring, screws and bolts?

* in the track of the exercise asks to insert the tolerances in the drawing, but how should these be calculated? a my thought was that, taking for example the connection between the number 1 and the shaft 2, to subtract to the maximum width of the circumference of the piece (diameter 36) to that of the larger cylinder of the shaft (diameter 28 with eccentricity of two) getting a maximum dissection of 2 mm. is it right as reasoning or is it completely wrong as a road?

* in the drawing there are quotations of gorges and threaded pieces. for threaded pieces I found a table on the book which for example, for m42 x 2 tells me that the drilling diameter is 40 mm, but from the theory I know that it is 42 refers to the nominal diameter and 2 the step, what is the measure I have to adopt on the drawing? As for the throat, I did not find any connection to the drawing that helps me find the size of the throat, how should I proceed? also, in the design as listed compartment? with the norm or size in mm?

* the specific track to extract unified details, among these should I draw only pieces ranging from 1 to 8 or even pieces like spring, screws and bolts?