CristianT

Guest

Good evening to all,

I would have a doubt that I couldn't find answers.

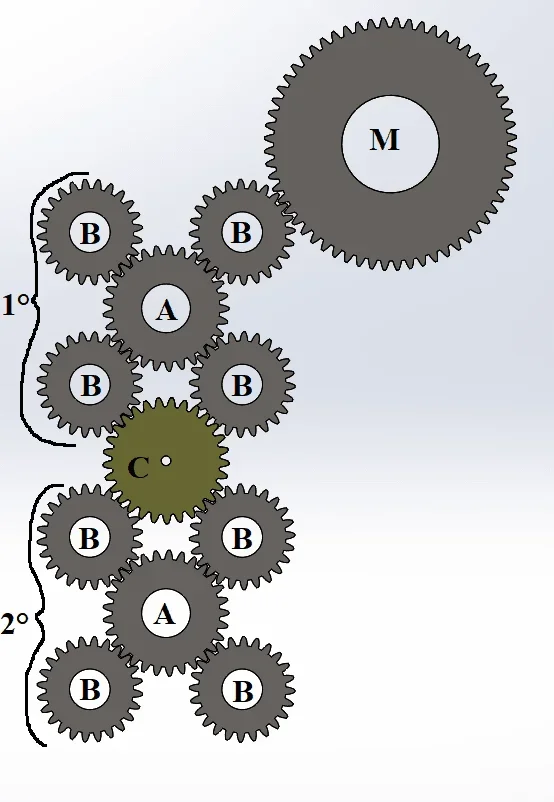

with a 2.5 module, we have:

- a moving wheel m

- toothed wheel b (z=24)

- toothed wheel (z=29)

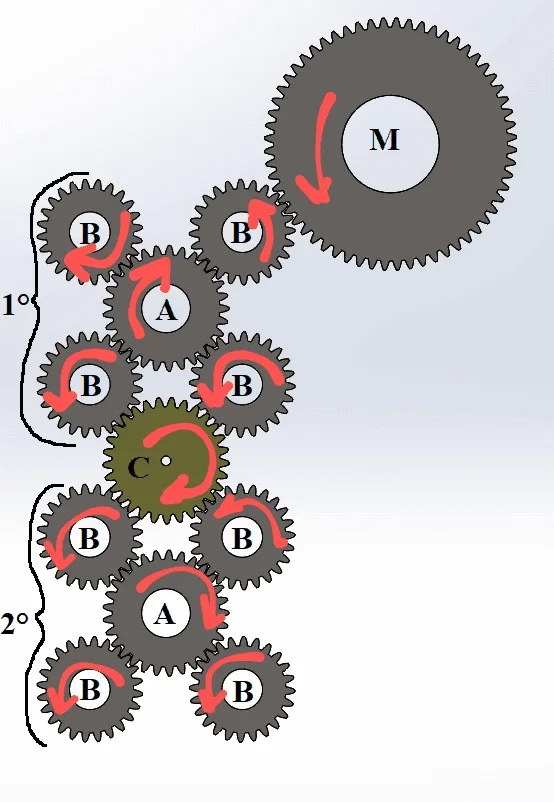

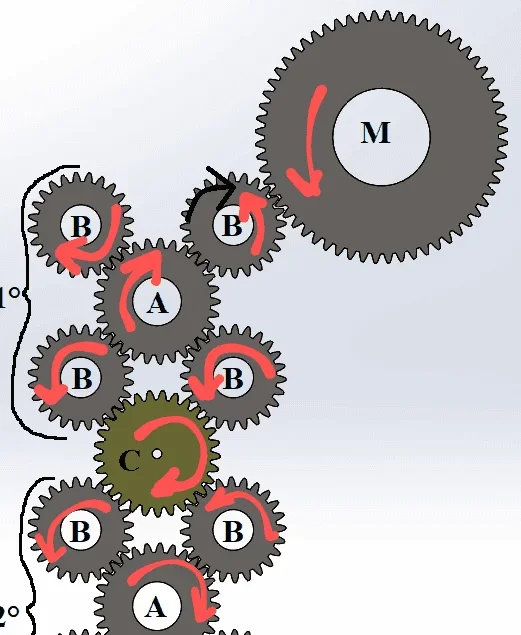

imagining to connect the 1st block with the 2nd as in figure, I have special conditions for the toothed wheel c?

i.e., in addition to having the same module and tangent primitive diameters, for the engraving of this closed circuit, do I have any condition to respect on the number of teeth of the wheel c or on the positioning or anything else that escapes me?

thanks to everyone in advance.

cristian.

I would have a doubt that I couldn't find answers.

with a 2.5 module, we have:

- a moving wheel m

- toothed wheel b (z=24)

- toothed wheel (z=29)

imagining to connect the 1st block with the 2nd as in figure, I have special conditions for the toothed wheel c?

i.e., in addition to having the same module and tangent primitive diameters, for the engraving of this closed circuit, do I have any condition to respect on the number of teeth of the wheel c or on the positioning or anything else that escapes me?

thanks to everyone in advance.

cristian.