Eurosoft srl is based in Tuscany, Italy and is a specialist in the development of sheet metal design and manufacturing software for HVAC manufacturing companies. Eurosoft has over 30 years of experience in this area and their focus is on supplying software and systems that simplify the manufacturing process for HVAC ducting projects. Their solutions ensure that customers can fully utilize the capabilities of their existing machinery and efficiently manufacture high-quality sheet metal products.

Eurosoft’s knowledge of production systems, design features, customer operational preferences, and the way in which options are made available to the end-user is fundamental to their customer’s success. Using this knowledge Eurosoft has developed proprietary sheet-metal design and manufacturing software that can handle many industry-specific constraints.

Eurosoft bases Sync3D on Solid Edge OEM

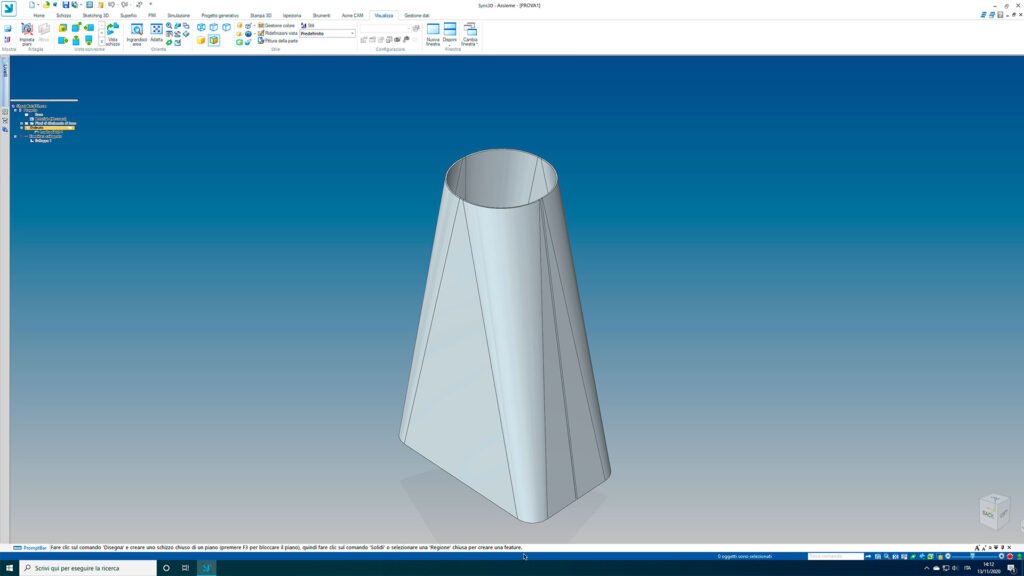

Eurosoft has applied their experience and know-how of sheet metal design and manufacturing techniques to the development of Sync3D. Sync3D is built on a proven mechanical CAD solution from Siemens Digital Industries Software, Solid Edge OEM. This is a very robust and programmable mechanical CAD environment that provides comprehensive capabilities for part and assembly modeling, and 2D engineering drawing creation. Of particular value to Eurosoft and their manufacturing customers, Solid Edge has a comprehensive sheet metal design environment that is integrated closely with the core mechanical part, assembly and drawing creation capabilities.

Eurosoft has used the Solid Edge API to integrate their own sheet metal design and manufacturing capabilities with the comprehensive sheet metal design environment that is an integral part of Solid Edge. This provides an excellent solution for manufacturers of sheet metal components with a specific emphasis on HVAC ducting components and installations. Sync3D is seamlessly integrated into Eurosoft’s CutExpert CAD/CAM suite, to provide a complete design-through-manufacturing solution for these manufacturers.

A specific benefit to end-users of a Sync3D is that it provides a high degree of interoperability with other software solutions. Many sheet metal manufacturers are contractors and work with a wide variety of customers. Their customers may supply them with design data in a wide variety of CAD data formats. The direct modeling mode of Solid Edge (synchronous technology) makes it possible for the manufacturer using Sync3D to modify these models directly to adapt them for specific manufacturing requirements.

Avoiding issues that impact existing HVAC design software

Eurosoft recognizes that there are existing software solutions available for the design of HVAC ducting. indeed, Eurosoft has developed converters to translate CAD data from these systems into manufacturing instructions. However, these software solutions can have errors due to many factors. This includes the incomplete definition of 3D models in the CAD software, and a lack of understanding of how parts will be manufactured.

Further examples of incompleteness with existing HVAC design software can include incomplete definition of the materials used, the type of joints used, and the identification codes of the parts. As a result, the use of these systems and their integration with manufacturing is often far from satisfactory. These solutions require a verification phase that in addition to being time-consuming, does not ensure zero error levels. In contrast, Sync3D software recognizes the specific constraints for the design and manufacturing of sheet metal components.

You can contact Eurosoft directly or download a PDF guide to find out more about Sync3D and Eurosoft’s other solutions for the design and manufacturing of sheet metal components. You can also contact Siemens to find out how you can create unique, industry-specific software applications based on our mechanical CAD base using our Solid Edge OEM development toolkit.