Trumpf Inc. is expected to introduce the latest, enhanced version of its TruPrint 2000 3D printer in the United States at this year’s Lab Day Chicago. Hosted by LMT Communications Inc., Lab Day Chicago is the largest gathering of the dental laboratory community in North America and will take place on 22-24 February.

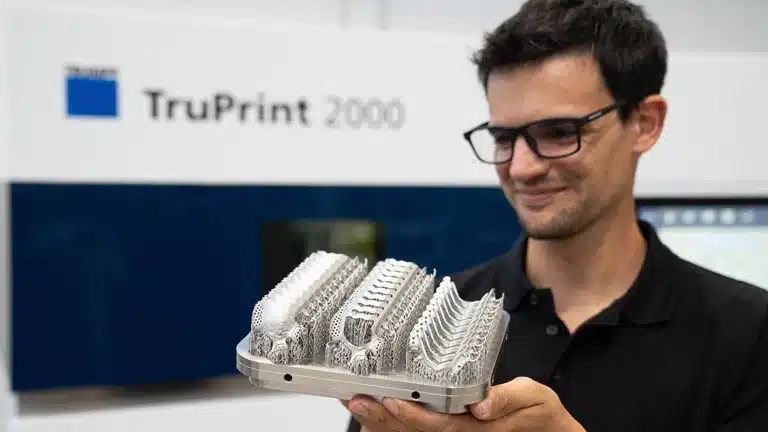

The new TruPrint 2000 3D features a square build plate and a 500-watt integrated fiber laser, with the basic configuration having a 300-watt laser. According to Trumpf, thanks to the square build plate, dental technology companies can print up to 36% more removable partial dentures than they could on a comparable round build plate.

“The updated TruPrint 2000 is further optimized for mass production. Users from all industries benefit from the machine’s high productivity,” said Miguel Verdejo, Additive Manufacturing Product and Project Manager at Trumpf’s Laser Technology Center, in Michigan. “In addition to the upgrades of the TruPrint 2000, the machine has the process monitoring and calibration features found in all TruPrint machines. Ensuring repeatable and high-quality parts is the top priority for Trumpf 3D printing, especially in critical areas such as medical and dental technology.”

Each of the TruPrint 2000’s two lasers can reportedly process the entire build plate simultaneously. Medical technology manufacturers use the 3D printer to produce skull plates, spine cages, and knee joints made of titanium.

Recently, TRUMPF provided 3D printing technology to Airbus Helicopters, who used metal 3D printing to produce components for the electric-powered CityAirbus, the experimental high-speed Racer helicopter, and the Airbus A350 and A320 passenger aircraft, among others.