Effectively managing product information across parts, assemblies, and products is critical for any organization. But this is a tall order if you’re working with a disjointed tech stack. So how can you make sure everything works together to support operations while also getting products to market on time? By using Windchill as your PLM solution for bill of materials (BOM) management.

Quick Review

What Is Windchill PLM?

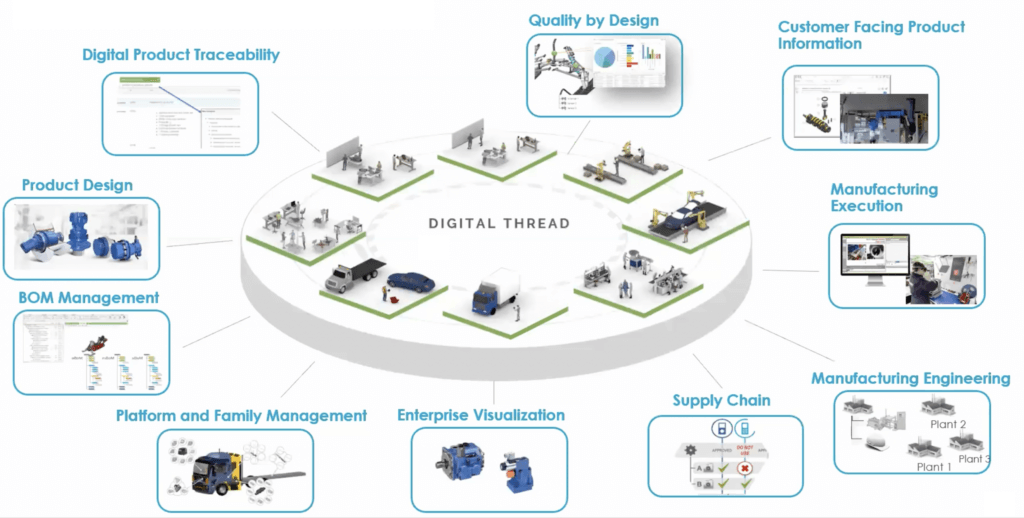

Windchill PLM is a product lifecycle management solution from PTC. Windchill organizes all your digital product information, keeping track of the data for parts, assemblies, and products throughout design, development, maintenance, quality control, and end of life. All this information is created, maintained, and analyzed within Windchill to give your entire organization a single source of truth for improved collaboration.

Using a PLM solution like Windchill makes it easy to generate and support an organizational digital thread.

What Is a Bill of Materials (BOM)?

A bill of materials, also known as a BOM or product structure, is a comprehensive list of the raw materials, components, assemblies, and supporting documentation needed to manufacture a single product. It’s essentially a recipe for how to create a product that can be easily shared between team members and partners to communicate more effectively.

Windchill PLM comes with all the tools you need to create a BOM for any of your products. Ensuring each BOM is up to date is a huge challenge in manufacturing operations. However, Windchill’s part-centric approach ensures manufacturing runs smoothly, with features that allow your team to track their modifications, offer substitutions, and more.

A bill of materials (BOM) is essentially a recipe for creating any product.

What Does Part-Centric Mean?

A BOM is made up of the parts that create assemblies, which ultimately create products. In the physical world, a part is made up of lots of information:

- Materials

- Documentation

- Form, fit, function

- Lead time

- Cost

- Shop floor routing

- Supplies

- Regulatory compliance

- FMEA

- Inventory

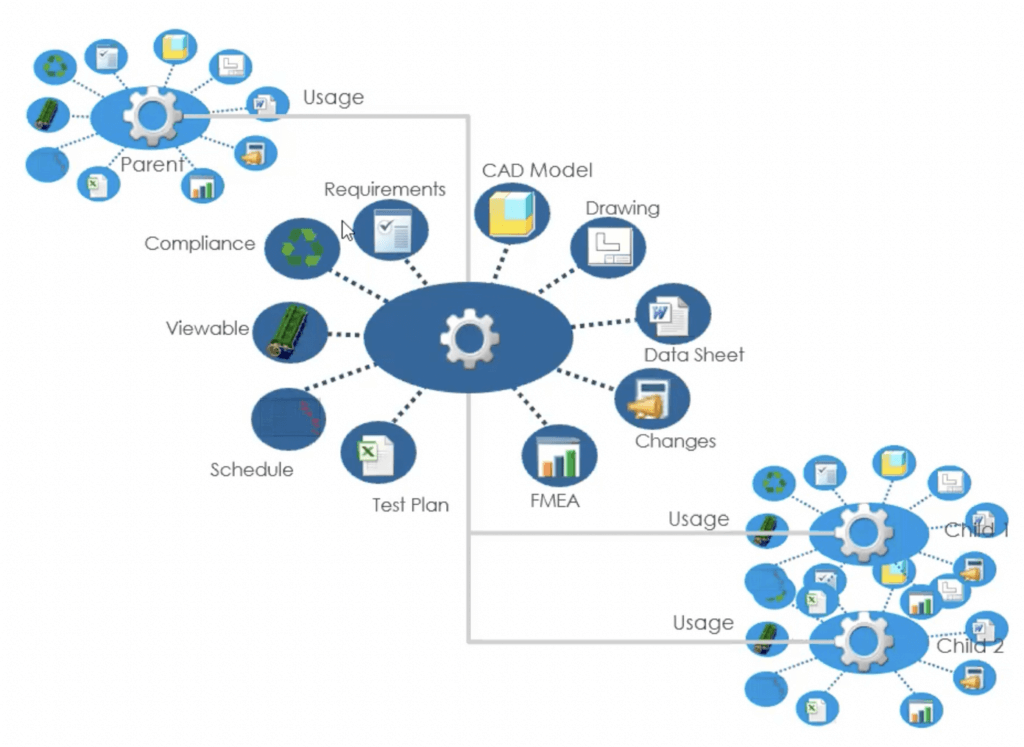

Within Windchill PLM, a Windchill Part represents a component or an assembly. In the digital world, a part is described by:

- Number or name

- Lifecycle state

- Additional attributes like weight and material type

- Relationships to other parts

Windchill takes a part-centric approach to BOM management. Organizing your data in this way makes it easy to link each part to all the information that describes it and also link it to other Windchill parts.

Windchill BOM Management

Components of a BOM

The Windchill interface contains a complete set of data for all your parts, ensuring every member of your team has access to the info they need. There are specific tabs for:

- Structure, which includes the current BOM, plus the BOMs of other parts. This has all the documentation and CAD files that are associated with any assemblies. Within this tab, part replacements and substitutions can be defined.

- Related objects, including other assemblies that are part of a larger project, and the various iterations of each part.

- History, which has detailed documentation of everything that has been changed on the part, including who did it, when they did it, and any comments they included.

- Documents that are assigned and created for this assembly, such as work instructions, CAD files, etc.

The entire Windchill interface is customizable, and there are add-on modules specifically for AML/AVL parts.

Tutorial: Creating a Part for BOM Management

- Start in the browsing menu

- Select product

- Create new part

- Define the part, including part type (customizable based on your Windchill installation)

- Fill out the required part attributes

- Number (can be auto-generated or put in manually if using a specific numbering structure)

- Assembly mode

- Source

- Description

- Part number

- Drawing number

- Materials

- And more—attributes can be customized during Windchill installation

- (Optional) Create CAD document, which creates a placeholder CAD file to be updated later (it is also possible to create CAD files separately and link them later)

- Open part

- Navigate to structure tab to build BOM

- Create new part and add to BOM or insert existing part (which automatically includes all subcomponents)

- Repeat until BOM is complete

Other Windchill Features

Now, you may be thinking, “I don’t create parts, I just work in the shop.” For those who need to find information but don’t need to make changes to parts, Windchill PLM offers plenty of features.

Windchill replaces loose, disjointed (and often out of date) documentation with an easy-access, up-to-date repository of data.

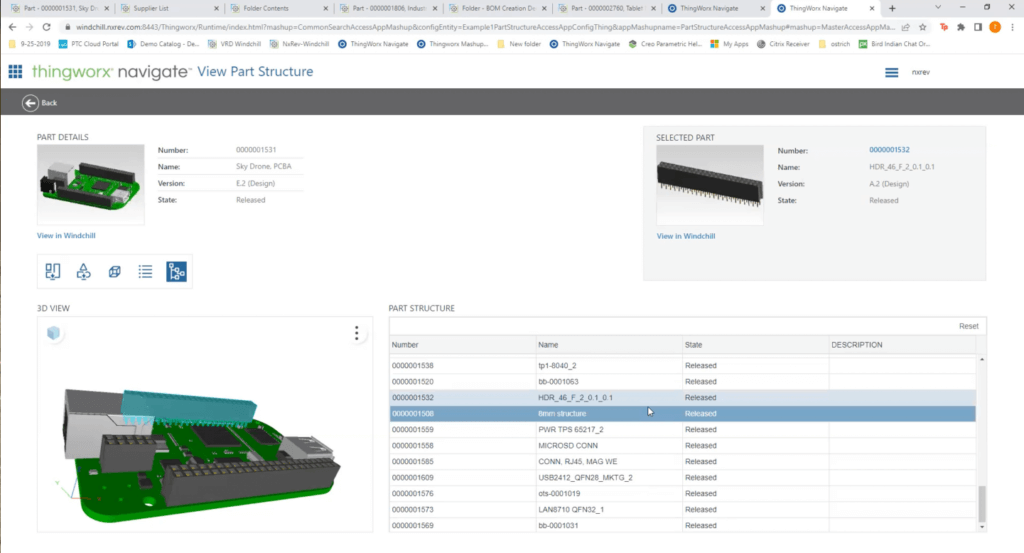

Thingworx Navigate

Thingworx Navigate is a web-based portal that makes it easy for your team to browse, find, and extract the information they need from Windchill. Users can:

- View design files and drawings, including any step files, 3D CAD files, and supporting documents

- View and measure in 3D, including automated build envelope measurement, using Creo View (more on that below)

- View parts list or part structure, to easily search for whatever you need within the assembly and highlight selected parts

- View documents and document structure

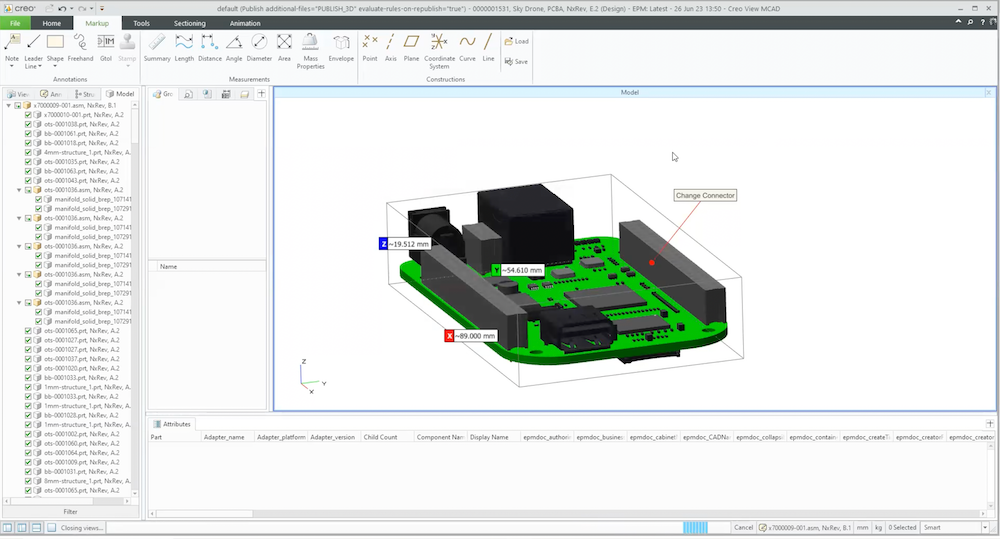

Creo View

Creo View is a lightweight viewing app for non-engineers and non-designers to view and analyze files. It includes easy-to-use measuring tools for inspecting the entire assembly or individual parts within it. Notes can be added and shared among team members for improved collaboration.

Windchill—Essential for BOM Management

Getting products to market on time and within budget starts by aligning teams to the same product information. Windchill PLM allows you to capture, configure, and manage product information across the lifecycle, including BOM management. This significantly increases efficiency without sacrificing quality.

If you’re ready to get started with Windchill, we recommend finding a partner, like NxRev, who can help you throughout the initial installation, or walk you through the transition process from your previous solution. We even offer training for Windchill and other PTC products, to ensure you get the most out of the solutions you’re paying for.