3D printer manufacturer Stratasys has announced that its J5 MediJet 3D printer is being used by the University Hospital Birmingham (UHB) to 3D print tailored cutting guides used in craniomaxillofacial tumor surgery.

The 3D printed guides can be personalized to meet patient specific requirements. This is said to improve outcomes for head and neck cancer patients, and reduces surgery times by up to three hours. 3D printed surgical guides have become an ever more widely used application.

Previously, these surgical components had to be made by cutting and bending pieces of metal by hand during operating procedures, a time-consuming process with a significant margin for error. The hospital’s surgical team can now use patient scans to quickly 3D print the devices, achieving resolutions of 150 microns.

“In addition to saving up to three hours of surgery time, 3D printing also enables much better surgical planning. Using patient scans, the team is able to create 3D visualizations based on the distinct anatomy of each patient – and then leverage 3D printing technology to produce both anatomical models and personalized surgical cutting guides ahead of the actual operation,” stated Stefan Edmondson, Consultant Clinical Scientist (Reconstructive Science) at the University Hospital Birmingham.

“This capability means we can not only accurately predict the surgery before it’s done, but that we have the tools to ensure that the meticulous pre-surgical planning can be executed with the utmost precision.”

Stratasys’ J5 MediJet 3D printer

Launched back in 2021, the full-color J5 MediJet 3D printer is specifically designed to meet medical applications. In addition to tailored surgical guides, the J5 MediJet is optimized for the production of patient-specific anatomical models and medical tooling.

With a 140 x 200 x 190 mm build volume, this 3D printer boasts multi-material capabilities, and is compatible with a range of biocompatible 3D printing resins. In particular, the J5 MediJet supports rigid, rubberlike, transparent, and opaque resins for over 500,000 color combinations.

The J5 MediJet is also notable for its high productivity. The 3D printer’s simplified additive manufacturing workflow incorporates automatic build tray arrangement, model corrections, and 3MF file format support. Moreover, its compact footprint of 651 x 661 x 1511 mm makes it well-suited to hospital environments.

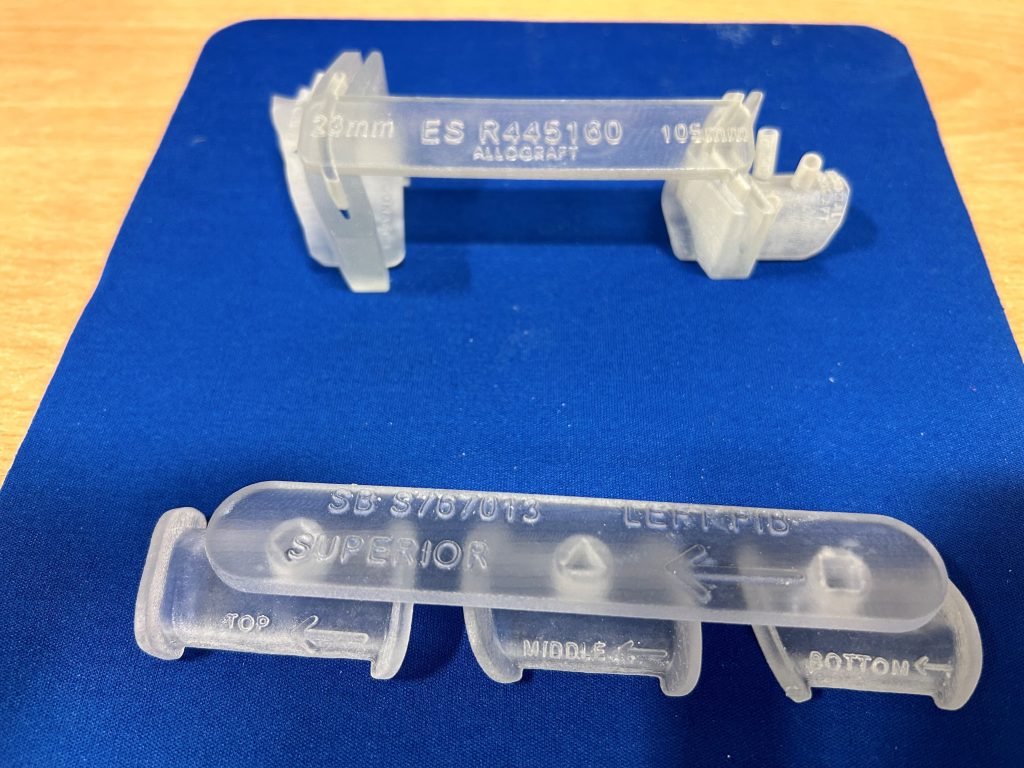

3D printing personalized surgical cutting guides

The personalized surgical guides are 3D printed using Biocompatible Clear MED610. This rigid and transparent resin is ideal for applications requiring long-term contact with skin (over 30 days) and less than 24 hours contact with tissue, bone or mucosal membranes.

Stratasy’ GrabCAD Print software is used alongside its MediJet 3D printer to produce the guides. The software’s automatic support building capabilities are said to contribute to the overall end-to-end time savings offered by 3D printing.

Taking accurate molds of a patient’s fibula and transplanting them into an specific area of the head or neck, while ensuring bone tissue is kept alive, is an incredibly complex process. According to Stratasys, 3D printing offers superior capabilities over conventional methods in conducting such procedures.

“In this scenario, if the angles you’re cutting at aren’t absolutely perfect, the bone won’t fit and there will be a higher tendency for the body to reject it, leading to significant discomfort for the patient,” explained Edmondson. “Thankfully, the 3D printed cutting guides are accurate to micron level, ensuring the fibula is cut to the best possible fit for our patients.”

This is not the first time University Hospital Birmingham has leveraged Stratasys 3D printing technology. For instance, UHB has previously acquired a Stratasys Connex multi-material 3D printer through the company’s UK-based reseller Tri-Tech 3D.

“Stratasys is the gold standard of 3D printers – something that is exemplified in the J5 MediJet,” added Edmondson. “Beyond its ability to produce highly accurate cutting guides and brilliantly vivid anatomic models that are biocompatible and sterilizable, it is really easy to use, which makes it a winner with our team.”

Optimizing surgical procedures with AM

The use of 3D printing to improve surgical outcomes is nothing new. It was recently announced that metal 3D printing technology from Bright Laser Technologies (BLT) has been used to produce key components for the world’s first flexible robotic system for minimally invasive brain surgery.

Called MicroNeuro, this robotic system was developed by a team from the Centre of Artificial Intelligence and Robotics (CAIR) of the Hong Kong Institute of Science & Innovation, Chinese Academy of Sciences. MicroNeuro reportedly addresses challenges associated with fragile brain tissue and limited space, overcoming the limits of hand-eye-brain operation in the process.

The CAIR team leveraged BLT’s BLT-A160D metal 3D printer to fabricate the MicroNeuro’s multifunctional distal head caps. The components feature an intricate design, and wall thicknesses as low as 0.15 mm. According to BLT, these features would be difficult to achieve using conventional manufacturing methods.

Elsewhere, 3D printer manufacturer 3D Systems offers hybrid maxillofacial surgical guides as part of its Virtual Surgical Planning (VSP) medical planning portfolio. These 3D printed surgical guides are designed to provide surgeons with greater site visibility and procedural confidence during maxillofacial operations. 3D printed using the company’s LaserForm Ti and DuraForm ProX PA materials, the guides are easy to assemble and can be customized to embed multiple cutting/drilling locations onto a single device.