Simulation in the engineering space empowers designers to create, test, and revise ideas with a speed and complexity not possible with traditional means alone. Just as simulation has enabled faster and more calculated development of products across industries, its own evolution is rapid and crucial to understand. The current state of simulation in the engineering space is defined by its expanding role and evaporating limitations. The future of simulation is likely to see a similar explosion of computer-aided engineering (CAE) capabilities, scale, and scope.

CAE simulation and its constraints

In its formative years in the 80s and 90s, simulation was used almost exclusively for design validation. This is not to downplay the importance of these capabilities: simulation provided unparalleled answers to engineering questions of complex systems while reducing costs to test part viability. Initially, this was focused on mechanical interactions but rapidly expanded to fluid dynamics, material forming, electromagnetics, and much more. With this technology, engineers could predict a design’s behavior based on a huge array of imposed constraints and optimize the end product through virtual trial and error rather than engaging in destructive real-life testing.

The major limiting factor of these abilities was the processing power available at the time. With the exponential increase in computing power, along with improved numerical schemes and better physical modeling (through physical theory, engineering talent, and software capability), simulation possibilities have exploded.

Simulation today

This leads us to the current state of simulation. We can process more variations of a given system with automated design optimization and far more complex models. Multiphysics has left the exclusive domain of academia and become working tools used across industries.

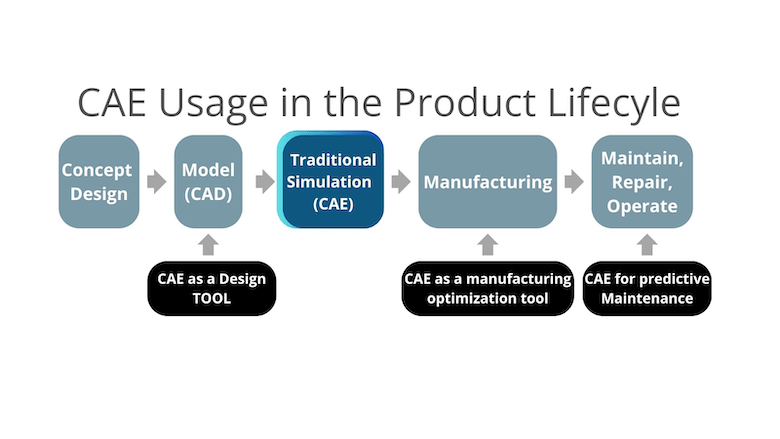

The expansion of speed and capability has seen simulation creeping out of its design validation box. CAE is being used in more areas of the product lifecycle than ever before. At the start, the earlier problems are caught, the cheaper and faster revisions can be made.

Simulation now has an ever present role in optimizing manufacturing processes. Modern tools allow for better predictions of forging, casting, injection molding, and much more. While these capabilities have existed for a while, improvements in technology and engineering practices have allowed simulation to play a more vital role across the entire production process.

Even after the product has begun its life with its client, CAE allows for better estimations as to the maintenance and repairs the design will need. Simulation allows engineers to better predict what is likely to fail first, and create maintenance schedules to mitigate problems. Operational advice can be given to the eventual user, based on the forecast provided by a CAE program.

The future of simulation in engineering

The future of CAE is bright. In the same way faster processes and smarter processes have enabled simulation to expand its role, upcoming tech and trends offer new possibilities for simulation in engineering.

Model-based engineering

Model-based engineering is being more consistently implemented in the manufacturing space across industries. 3D models offer a simplified, unified method of sharing information between concerned parties. The data they provide improves global collaboration and optimization efforts, with the 3D model serving as the source for all sorts of manufacturing and design information.

This data package already includes metadata, the model itself, inspection information, and more. While sometimes present, the next step for model-based engineering is to include CAE data: CAE constraints and simulation results should be a part of the data package that is passed around.

Integration of CAE capabilities into modeling applications can also help to remove some of the speedbumps that come with data transfer to a separate, specialized simulation application.

The required AI discussion

There is hardly a “future of” or predictions piece publishing in the past few years that doesn’t mention AI in some capacity, and this will be no different. Artificial intelligence is here to stay, that is not in doubt, but its role in simulation and engineering as a whole is still far from being clearly defined.

An exciting prospect involved deep learning technologies becoming smart enough to handle large categories of problems in generalized circumstances. Perhaps underlying partial differential equations issues could be solved in a fraction of the time it currently takes.

Another aspect of AI in CAE comes using generative design for model creation, and the utility of AI to consolidate such solutions. Generative design is going to continue to allow engineers to create hundreds or thousands of iterations of a product to be simulated. AI will likely be a vital tool in navigating these variations to get the most desirable results as quickly as possible.

Remote engineering

Remote engineering is not a new concept and a huge portion of engineering is still done on desktop applications. In the past, remote desktops offered an imitation of true web-based CAE applications. The last decade has seen a significant expansion of real CAE web applications, with engineering and CAE moving to the cloud. There has been, and will continue to be, a shift away from private server cluster usage to commercial offerings such as AWS, Azure, Google Cloud, and more.

Whatever technology is used, remote engineers offer a way to centralize data and experience, while reducing IT overhead. Resources become more flexible, and the potential for collaboration is expanded. How this is adopted is dependent on an organization’s culture, user experience, and the associated costs involved.

Quantum computing: The far future?

Perhaps a little too far to discuss in depth now, but the power and potential of quantum computing offer tantalizing prospects for the 3D simulation industry. As we have seen, the removal of technical limitations sees CAE tend to explode in functionality, scope, and impact of the industries it touches. Predicting the exact outcome of this technology is difficult, but if it can deliver on its promise, the possible engineering applications are exciting.