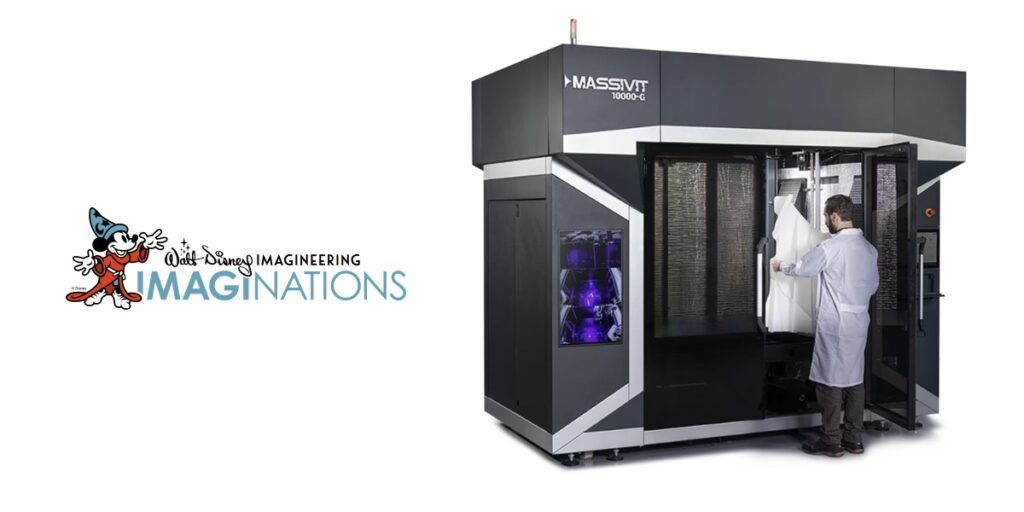

LOD, Israel, Feb 26, 2024 – Massivit 3D Printing Technologies (TASE: MSVT), a leading provider of industrial 3D printing systems, has received an order from Walt Disney Imagineering for the purchase of a Massivit 10000-G, the most advanced of Massivit’s 3D printers.

The Massivit 10000-G is the latest of the company’s printers to be brought to the market from the company’s second-generation product line. The system provides high-speed custom manufacturing of large parts as well as industrial tooling and prototyping.

Walt Disney Imagineering – responsible for the creation, design, and construction of Disney theme parks and attractions worldwide – joins Massivit’s growing installed base of entertainment fabrication companies that use Massivit’s industrial 3D printers for production of large creative experiences in the USA and worldwide.

The Massivit 10000-G employs Cast In Motion technology and unique printing materials developed by Massivit. The first material developed for the Massivit 10000, CIM 500, enables direct printing of molds for production of composite material (carbon and fiberglass) components. The second material, CIM 84, launched in November 2023, has an ASTM E84 Class A flame rating compliant with the most stringent American fire and safety standards required for theme park construction. This material expands the market potential of the company’s offering. The material consumption of this second generation of printers is expected to be significantly higher than that of its first generation.

Erez Zimerman, Massivit’s CEO, remarked: “The signing of this agreement with Disney is an important foothold for Massivit in the theme park sector. This is an industry which still utilizes antiquated fabrication methods that demand extensive manpower . The clear advantages of Massivit’s technology – print size, print speed and advanced printing materials – will enable Disney to rapidly produce high-quality components that comply with the most stringent industry standards.”

About Massivit

Massivit 3D Printing Technologies is a leading provider of industrial 3D printing solutions for the automotive, marine, rail, furniture and themed entertainment markets. The company’s solutions enable cost-effective production of large custom parts, molds, and prototypes at unprecedented speed. Massivit’s vision is to transform manufacturing of large parts from traditional and outdated processes to ultra-fast, digital fabrication using industrial-grade materials. The company was founded in 2013 by a team of experts led by Gershon Miller, founder of Objet Geometry. Massivit’s headquarters are based in Lod, Israel. The company provides comprehensive services to its worldwide community via a network of distributors. For more information, visit https://www.massivit3d.com.