Mastercam proudly teamed up with our partners at Hermle to create a gingerbread house to celebrate the winter holiday season.

When we approached Hermle with the idea of creating this festive piece, Kyle Brunner, Senior Applications Engineer at Hermle, was excited to get started and said the gingerbread house “belongs on a Hermle.”

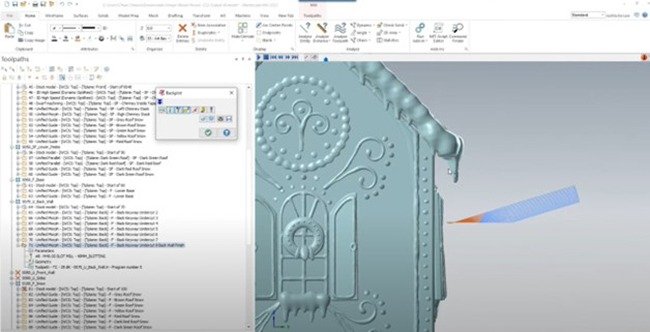

Working with Chad Chmura, Sales Engineer II at Mastercam, Kyle decided it would be best to run the gingerbread house on Hermle’s C-42 Dynamic Machine. The C-42 is a full five-axis machine, and the house would be created with the 25K spindle and torque table to be able to move around the A and C axis. The blanks were prepared at the Mastercam headquarters and were shipped to Hermle.

Five axis slotting was used for the intricate hanging icicles, which Kyle said “really sets off the demo piece. Without the overhang and delicate features, it would basically just be a box”. Using the full radius on the slotting saw allowed Hermle to work their way around and stay off the windows and icicles inside the undercut, highlighting Mastercam’s programming.

The design of the roof was programmed on a three-axis operation using an Equal Scallop toolpath, which makes the beautiful cut pattern. Hermle converted the three-axis toolpath to five-axis in order to add the chimney on a tilt, which Chad described as a “unique way of programming a part like this.” He added that “it’s an obscure toolpath to use, but if you keep it simple, make your three-axis motion first and then make it safe, it’s an effective way of programming a multiaxis machine.”

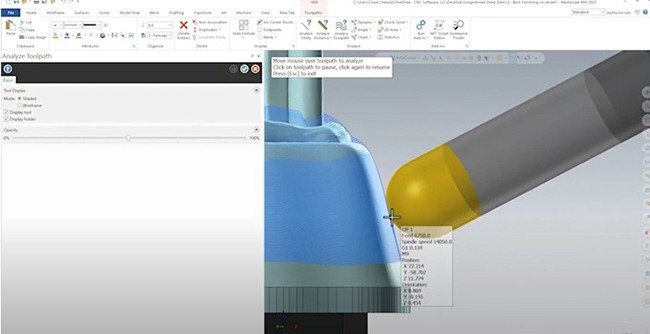

Another unique feature of the gingerbread house that put Mastercam and Hermle to the test was the snow around the bottom of the house. The challenge of the snow stemmed from its organic surface, but it was also a mesh composed of a lot of triangles that have normals which face all over the place. When running a toolpath normal to those faces, the tool axis control jitters a lot.

To help with this, Mastercam created a powerful utility called smoothing. While the smoothing function helps to eliminate reversals and smooth tool access control, Mastercam’s ability to tune the default smoothing allowed us to optimize the surface finish on the Gingerbread house.

The goal of the gingerbread house was to really show what Mastercam and Hermle can do when paired together on a complicated part. With the gingerbread house, Mastercam and Hermle optimized every toolpath to get the best surface finish.