SOLIDWORKS Costing (available in SOLIDWORKS Premium) is a powerful tool that can estimate production costs for manufactured components using parameters such as raw material costs, setup time, operation times, scrap reclamation, and more.

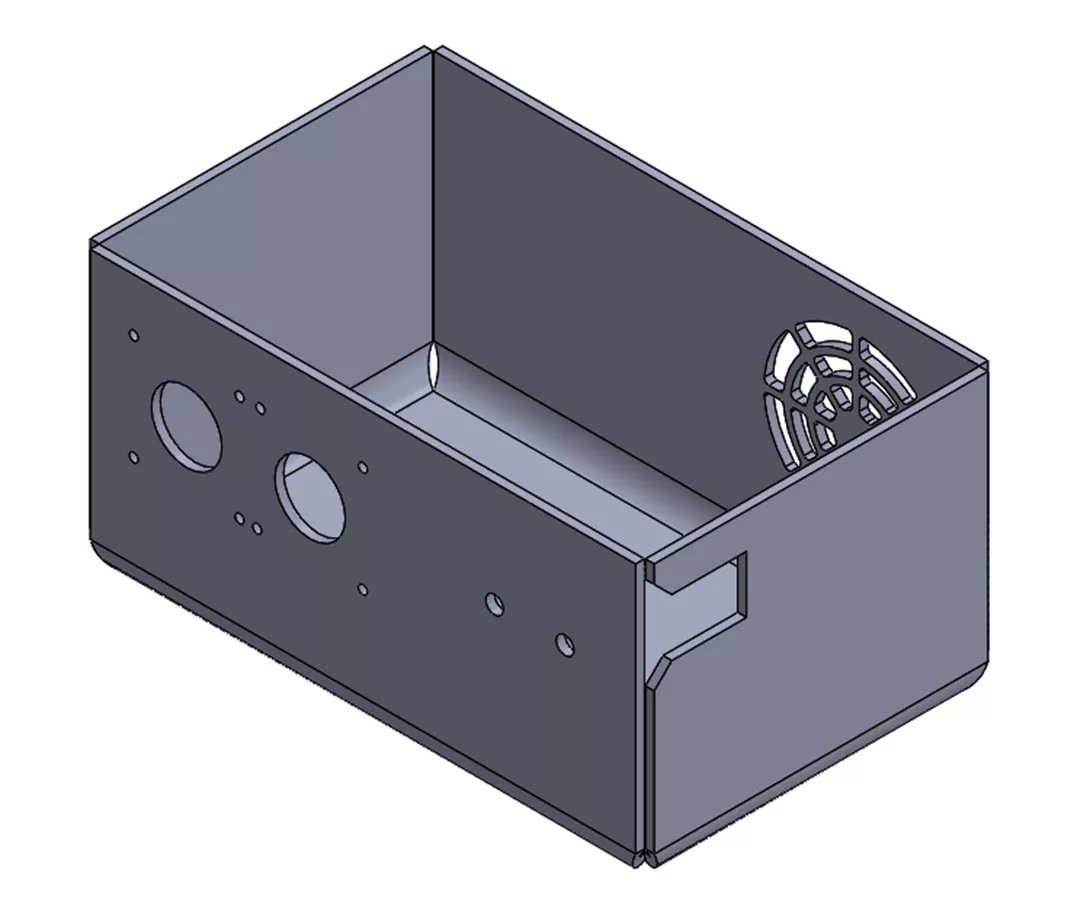

But what if your company has long lead times for material orders, and you need a quick material estimate early in your design cycle before finalizing a design? Let’s look at an example where we estimate material needs for a run of 100 sheet metal enclosures.

Estimation Process

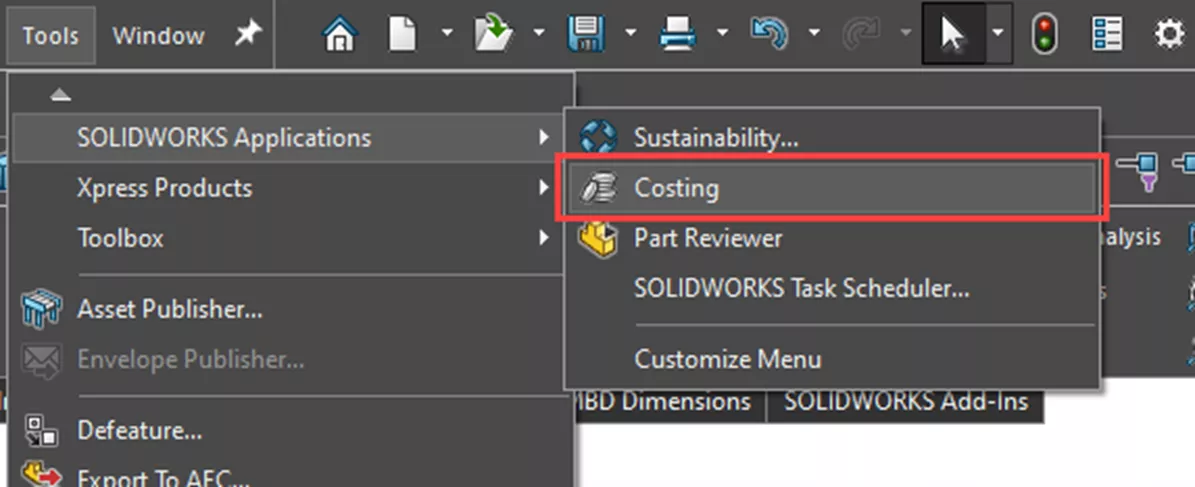

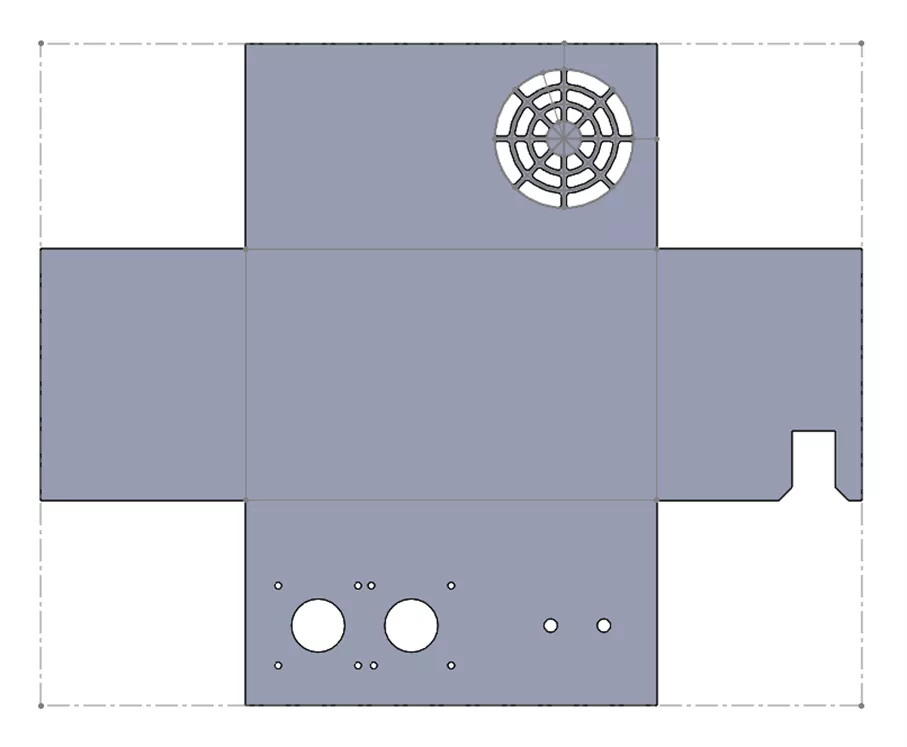

Starting with the sheet metal component pictured above, we can access the SOLIDWORKS Costing tool through the Evaluate tab or by navigating to Tools > SOLIDWORKS Applications > Costing.

Once opened, Costing will appear on the right side of the interface as a tab on the task pane.

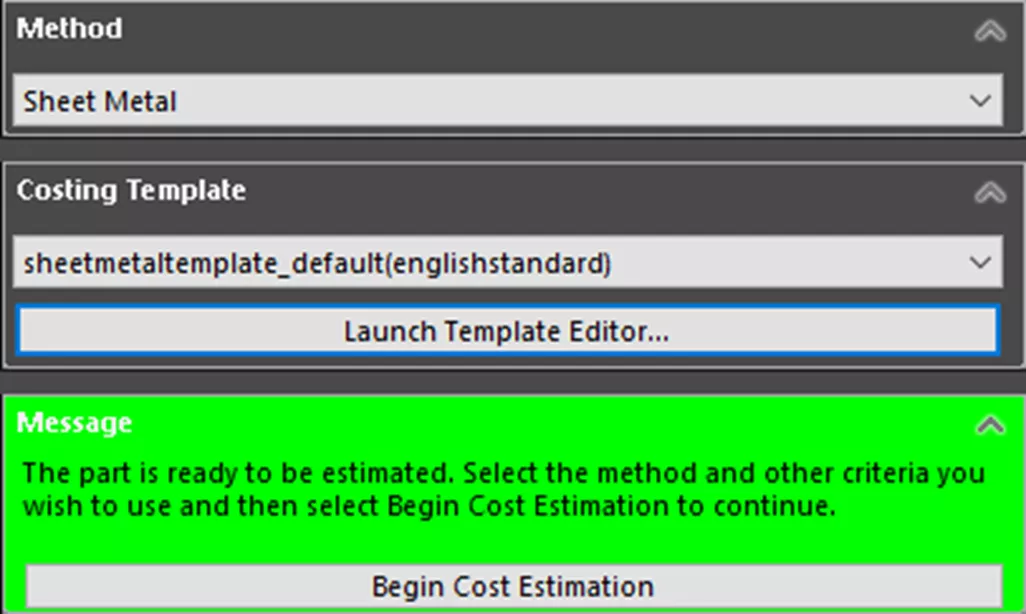

As mentioned previously, Costing can calculate the cost associated with a variety of manufacturing processes, including sheet metal parts, machined parts, multibody parts, assemblies, molded plastic parts, casting, multibody weldments, and 3D printed parts.

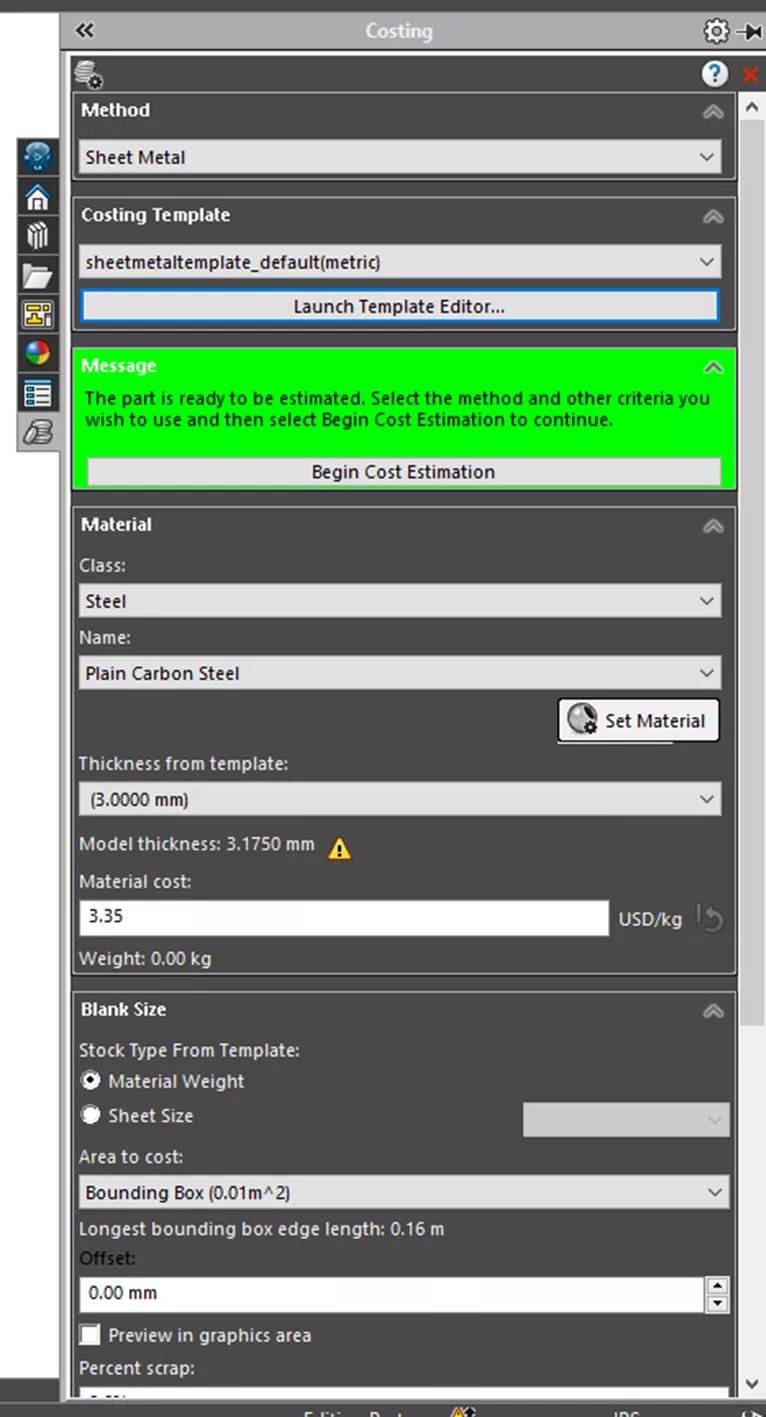

For this example, we will use the “Method” for sheet metal parts (as shown at the top of the image to the right).

Also visible in this dialog are options for class of material (Steel), name of material (Plain Carbon), thickness (3.35 mm), and material cost (3.35 USD/kg).

All these values can be edited to match an organization’s specifications and parametrically updated in the future as market rates or required quantities change.

Costing Templates can also be edited to match internal process times and costs, but for this example, we will just be looking for a quick material estimation.

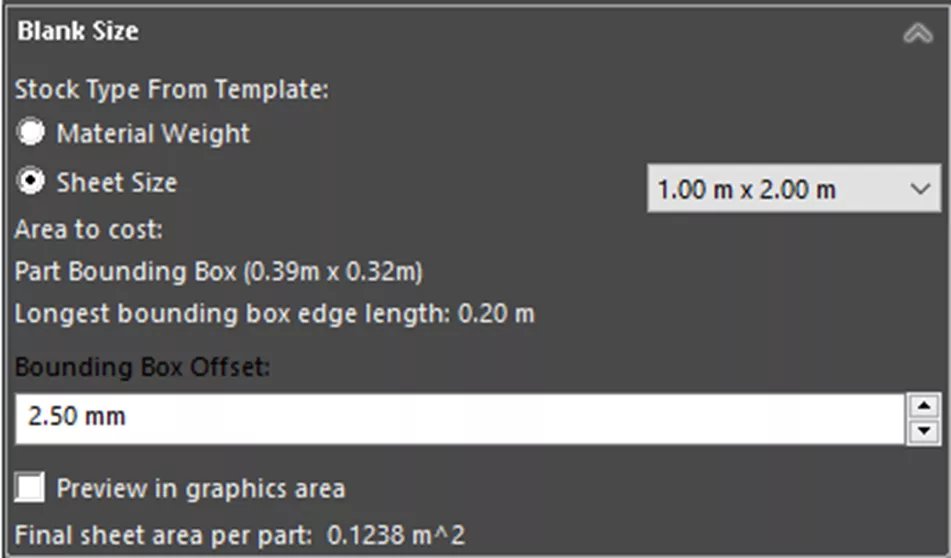

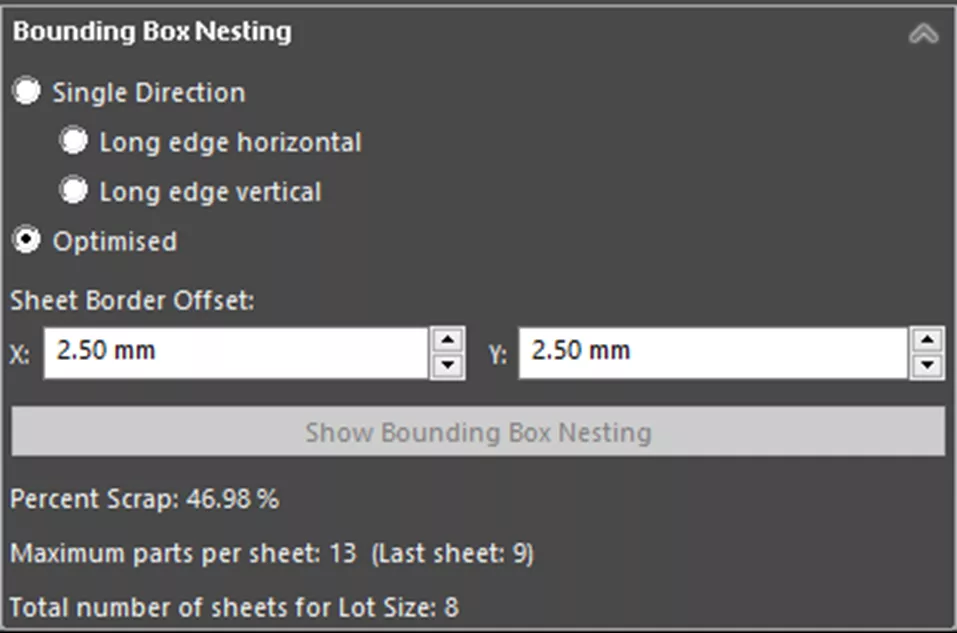

The next step is to specify our stock sheet size (in this case, 1.00 m x 2.00 m). We also need to establish any needed offset to the bounding box for the part based on the manufacturing methods. Here, we have input an offset of 2.50 mm.

This value is an offset from the flattened sheet metal component (as in the image above).

Next, we have options for how the part will be nested in the sheet, including forcing long edges to be either vertical or horizontal or letting SOLIDWORKS Costing optimize orientation for maximizing material utilization.

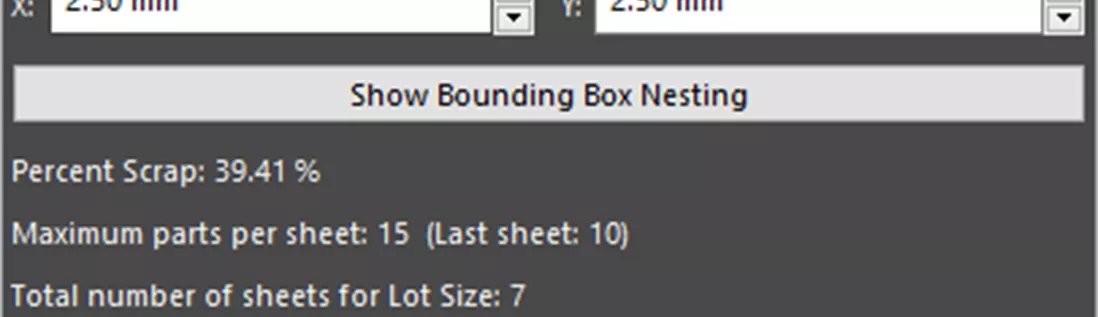

We will then establish the border offset for the sheet using 2.50 mm for the x and y directions.

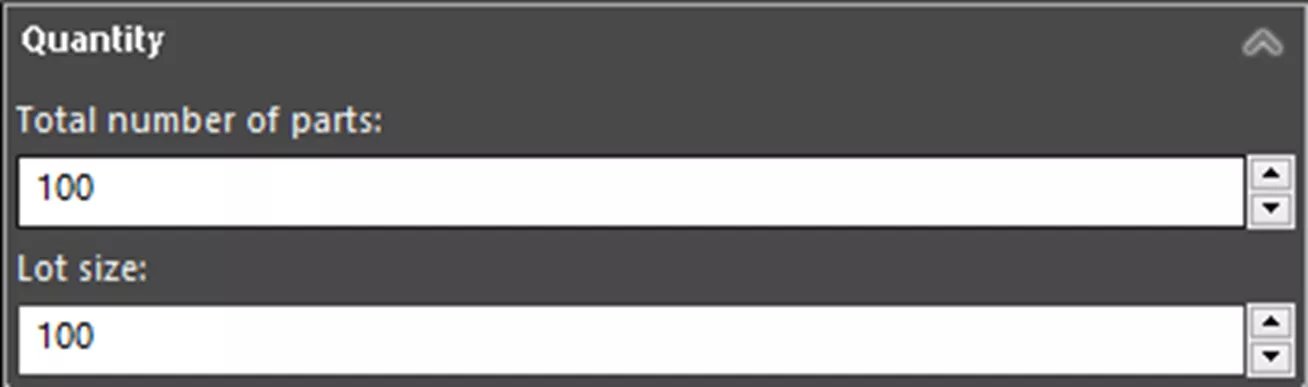

Lastly, we will set the total part count and lot size as 100 for this production run.

Once everything has been entered, click the button towards the top of the Costing dialogue to Begin Cost Estimation.

Once complete, we can review the results in the Bounding Box Nesting section.

We will need 7 sheets of material and produce 15 parts per sheet, except the last sheet with only 10 parts. Scrap estimation is 39.41%.

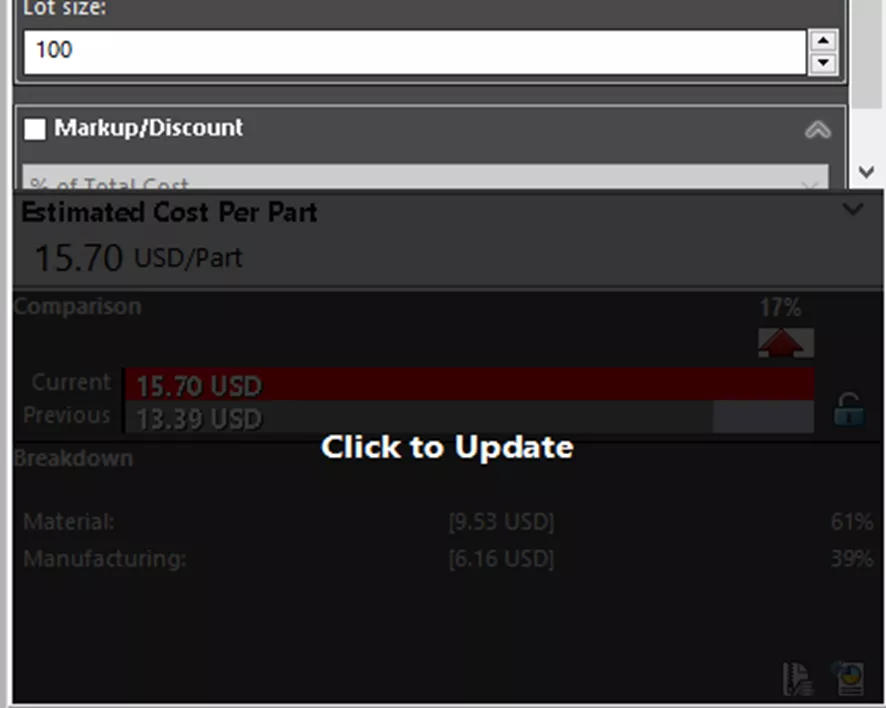

If we make any changes to our component, sheet size, quantity, or offsets, we can quickly update our estimate. In this case, I’ve increased the width of the part and increased both the part and sheet offsets by 2mm. When the changes are complete, select Click to Update at the bottom of the Costing pane to rerun the estimate.

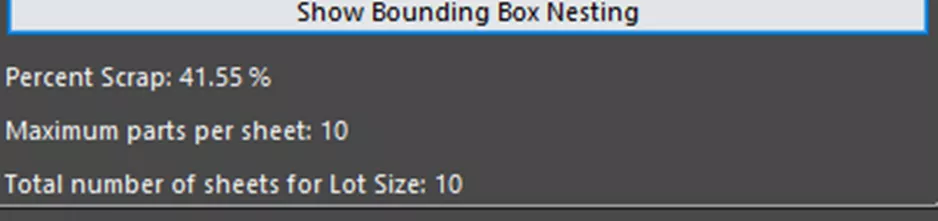

We can see these changes by returning to the Bounding Box Nesting section.

The changes increased the total sheet count from 7 to 10, parts per sheet from 12 to 10, and the overall scrap to 41.55%.

Conclusion

Generating estimates using SOLIDWORKS Costing early in the design process can be vital in increasing efficiency and reducing costs. With this information, you can better manage material lead times, refine designs to minimize scrap costs, and more effectively match or generate cost targets for production parts.