Why is tolerance standard tables important?

There are two commonly used manufacturing processes, either drawing-based manufacturing or model-based manufacturing. In both cases, placing manufacturing information is critical to producing precise parts. This manufacturing information may contain PMIs, drawing dimensions, tolerance information, notes, etc. Not all dimensions are placed with tolerance values, and these need to be considered based on tolerance standards, which may vary on part type.

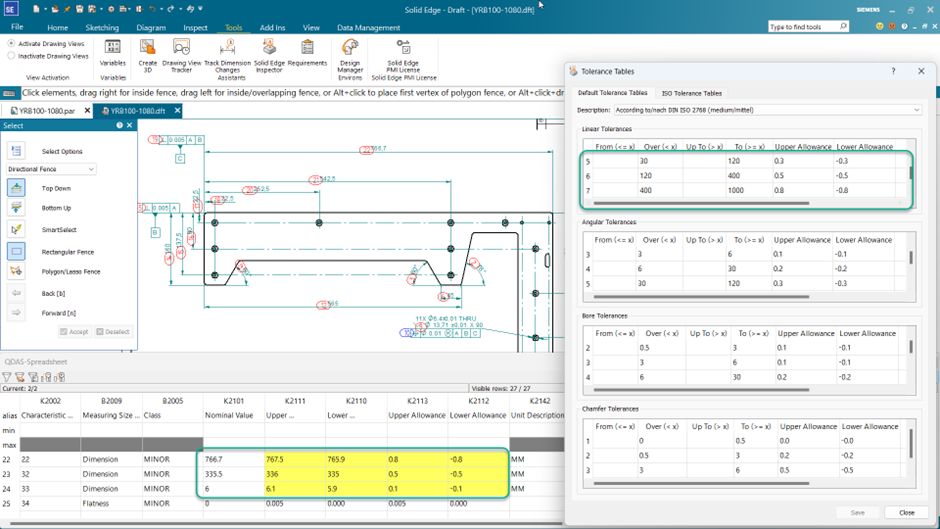

However, these tolerances have to be considered during the inspection planning process and are critical while inspecting the part for acceptance or rejection. Solid Edge Inspector provides a few tolerances standard tables out of the box as shown below. Solid Edge Inspector is an open application where you can define your tolerance standards so that the application will consider the tolerance values from the configured tables. Your organization can define multiple tolerance standard tables based on the requirement.

Below image shows default tolerance values (highlighted in yellow) which are considered from a tolerance standard table.

The video below explains the procedure for adding new tolerance standard tables that can be used for a specific part before the ballooning and characteristic identification process.

About Siemens Solid Edge

Solid Edge is a part of the Siemens Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, and provides an innovative and comprehensive approach to product development for the mainstream market.