What is Variational Stackup Analysis (VSA)?

Variational Stackup Analysis (VSA) in NX is a sophisticated variation analysis tool that helps predict and analyze how manufacturing variations affect product assembly and quality. By considering the cumulative effects of dimensional and geometric tolerances, VSA enables you to understand potential fit and function issues before parts go into production. This proactive approach to variation analysis is essential in today’s manufacturing environment, where tight tolerances and high quality standards must be balanced with cost-effective production methods.

At its core, VSA works by simulating thousands of assembly iterations using statistical methods to account for real-world manufacturing variations. The tool considers factors such as part tolerances, assembly sequences, and fixture variations to provide meaningful insights into product quality and manufacturability. This allows you to make informed decisions about tolerance specifications, identify critical dimensions that most significantly impact quality, and optimize assembly processes for better results. Whether you’re working on complex automotive assemblies, precision medical devices, or consumer products, VSA provides the analytical foundation needed to achieve consistent quality while maintaining reasonable manufacturing costs.

Validating an analysis

Before running a complete variation analysis, it’s essential for you to validate your VSA setup to ensure accurate and meaningful results. The validation process in NX acts as a preliminary diagnostic check, scanning your simulation parameters for potential issues or missing elements that could affect the analysis outcome. During validation, NX examines your tolerance specifications, measurement operations, move functions, and statistical parameters to confirm they are properly defined and configured. If any problems are detected, you receive immediate feedback through warning messages, allowing you to address these issues before investing time in a full simulation run.

Reviewing Variational Stackup Analysis results

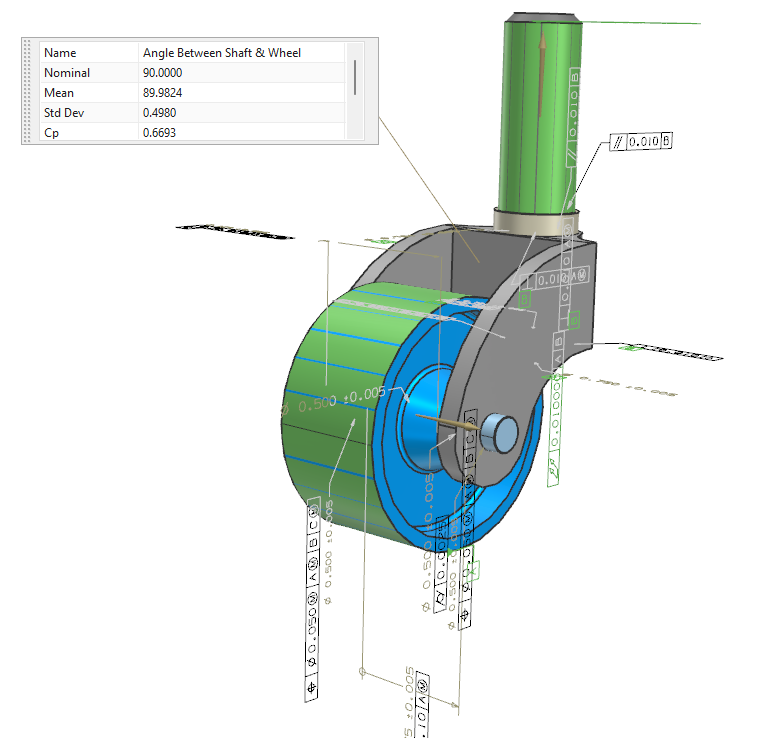

After completing your Variational Stackup Analysis, NX provides you with comprehensive statistical results that help you understand how manufacturing variations impact your final assembly. The results viewer presents clear visualizations and detailed statistical data, allowing you to quickly identify potential issues and areas where tolerance adjustments might be necessary. You can examine component contributor values, statistical distributions, and capability indices (Cp/Cpk) to understand which variations have the most significant impact on your critical measurements.

Through these results, you can make data-driven decisions about your design and manufacturing processes. The VSA output helps determine if your tolerances are too tight or too loose, identify which components contribute most to variation, and validate whether your design will consistently meet quality requirements in production. This insight is invaluable for optimizing your designs, reducing manufacturing costs, and ensuring consistent product quality. Whether you need to generate detailed reports for documentation or make quick assessments of design changes, the results interface provides you with the tools to effectively communicate and act on your Variational Stackup findings.

Updating PMI

The Variational Stackup navigator in NX provides you with a streamlined way to update Product and Manufacturing Information (PMI) based on your analysis results. Through this interface, you can efficiently modify tolerance specifications and dimensional requirements that have been validated through your variation analysis. The navigator allows you to directly update PMI annotations on your 3D models, ensuring that your documentation accurately reflects the optimized tolerances determined during your Variational Stackup studies. This seamless integration between VSA and PMI helps maintain consistency between your analysis results and production documentation, reducing the potential for errors in manufacturing.