I will concentrate on advancing turbomachinery, but first, allow me to begin with a personal reflection. There is a debate surrounding the origin of the quote “Give a man a fish, and you feed him for a day. Teach a man to fish, and you feed him for a lifetime,” but its timeless wisdom remains relevant. As a father of two children, it is my responsibility to impart all the knowledge I possess to them. It is the duty of a child to aspire to surpass their father. While I may not be an expert angler, I have a good grasp of the basics and enjoy taking my kids fishing a few times a year, whether it’s at a nearby lake or along the coast of western Sweden. This spring, my son received his first fishing rod, and his excitement to go fishing again this year indicates that he may soon excel beyond his father in this skill.

Shifting focus to a significant upcoming event that I am eagerly anticipating, though I may not consider myself an expert fisherman, I am recognized as a turbomachinery expert within the company I work for. While my expertise may be debated by the accomplished individuals part of the ASME (The American Society of Mechanical Engineers) ecosystem, I am enthusiastic to attend the premier ASME Turbo Expo once more to gain knowledge around advancing turbomachinery. The 2025 edition (June 16–20, 2025) will take place in Memphis, Tennessee, known for iconic landmarks like Graceland and a unique pyramid dedicated to fishing, beside the Mississippi River. In addition to reuniting with old friends and colleagues, I look forward to immersing myself in the latest research to further my expertise in the field with the ultimate goal of advancing turbomachinery.

Advancing turbomachinery at ASME Turbo Expo

Attending Turbo Expo provides a valuable opportunity to engage with engineering leaders from prominent companies, universities, and government labs. With a wide range of technical presentations available, participants can explore innovative methods for developing, testing, and ultimately advancing turbomachinery technologies in the context of power generation and propulsion. Engaging with industry decision-makers provides an opportunity to gain a competitive advantage becasue ASME Turbo Expo serves as a platform for exchanging knowledge and fostering professional and business growth in the field of power generation and propulsion technologies.

Simulation plays a pivotal role in comprehending the performance of complex machinery like gas turbines, particularly when the objective is advancing turbomachinery. Several research papers presented at ASME Turbo Expo 2025 focus on simulation, with a few examples highlighted below.

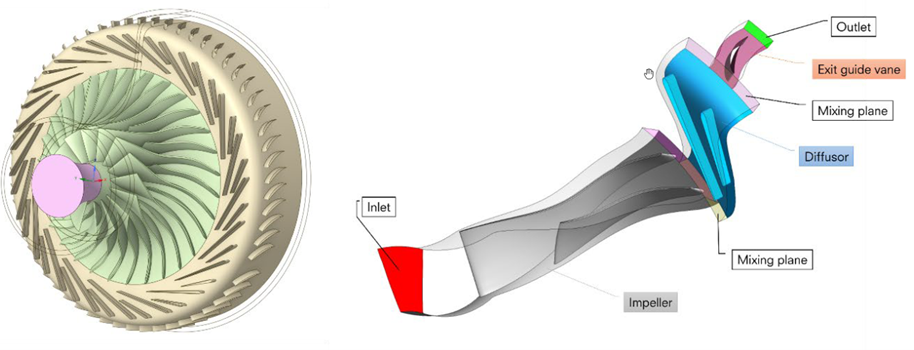

Numerical simulation and validation of as-manufactured NASA high efficiency centrifugal compressor using fully coupled FSI approach

GT2025-153737

Authors: Qingyuan Zhuang et al.

This study combines CFD aerodynamics with centrifugal forces and thermal expansion to accurately predict cold to hot transformation. This has been a joint research between Siemens DISW and IsimQ. With a lot of great input and good interactions with NASA. The model and measurements are delivered by NASA and open to the public.

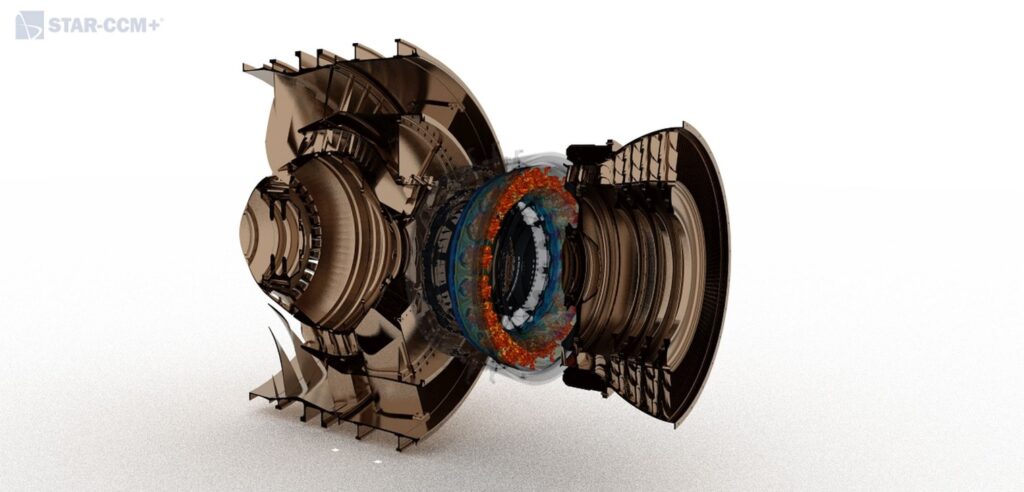

Co-firing hydrogen with natural gas for 9MW Siemens Energy dry low emissions combustor: part II – Large Eddy Simulations

GT2025-152877

Authors: Kexin Liu et al.

This is a combustion CFD research on simulating temperature and emissions for various hydrogen blends and pilot fuel ratio, with the built-in reactor network of Simcenter STAR-CCM+. This is compared to high pressure tests. This paper is a joint research between Siemens Energy and Siemens DISW as a contribution to advancing turbomachinery.

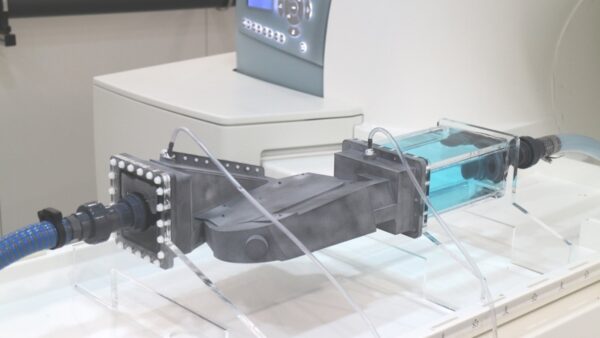

Impinging jet flows – CFD model validation using 3-D magnetic resonance velocimetry.

GT2025-153089

Authors: Scheuerer et al.

In this study an MRI machine (from Siemens) is used for flow measurements of impinging jets. In this study a great example of the importance of turbulence models are found. The LAG-EB model does a really good job in predicting advanced flow patterns and recirculation.

Aerodynamic design and CFD assessments of a hydrogen multistage axial compressor

GT2025-153406

Author: Arvind Prabhakar

This research presents a detailed aerodynamic design methodology based on mean-line design principles for a multistage hydrogen axial flow compressor. The multistage axial flow compressor is designed for a high flow application and a compressor pressure ratio typical of hydrogen pipeline transportation applications. However with a much lower number of stages, allowing for a reduction in the overall length, and weight of the turbomachine.

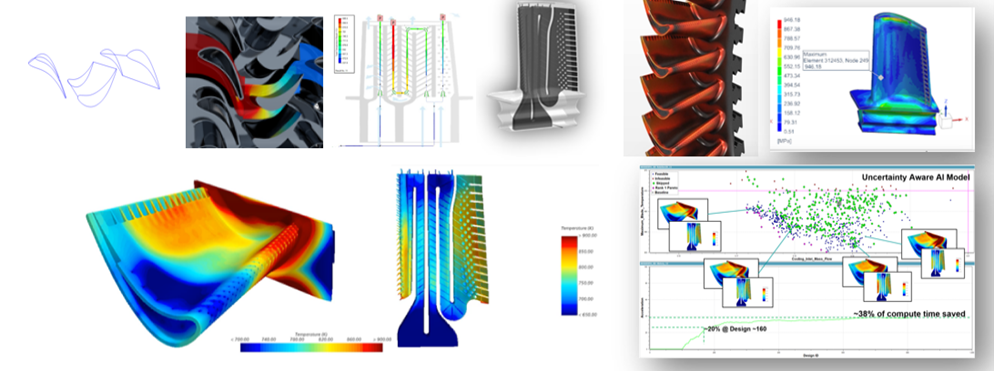

The reasons to use Simcenter STAR-CCM+ CFD software for advancing turbomachinery

Among Simcenter simulation technologies, in the field of turbomachinery, STAR-CCM+ CFD software plays a crucial role and there are more than a few reasons why it is one of the world-class solutions. Here are three of my favorites.

Number 1: The multi-physics capabilities enable accurate predictions of aerodynamics, heat transfer combustion, multiphase, stresses and strains across the entire gas turbine.

Number 2: It has ultrafast and robust automation and parallel meshing technology which are used for multidisciplinary design space exploration for real geometry.

Number 3: The fastest solvers, which are now also available for GPUs.

Which are yours?

I won’t pressure my children to pursue a mechanical degree. Instead, I share my passion for simulation technologies and the incredible aerospace and turbomachinery innovations developed by top engineers and researchers worldwide. By participating in events such as ASME Turbo Expo and either contributing to or learning from papers and presentations that utilize technologies like advanced simulation, engineers can have a profound impact on shaping the future of the aerospace industry and advancing turbomachinery applications

In fact, we would not be flying towards new adventures if people were fishing all day.