Thanks to the convergence of Artificial Intelligence and Physics

The challenges of structural adhesives

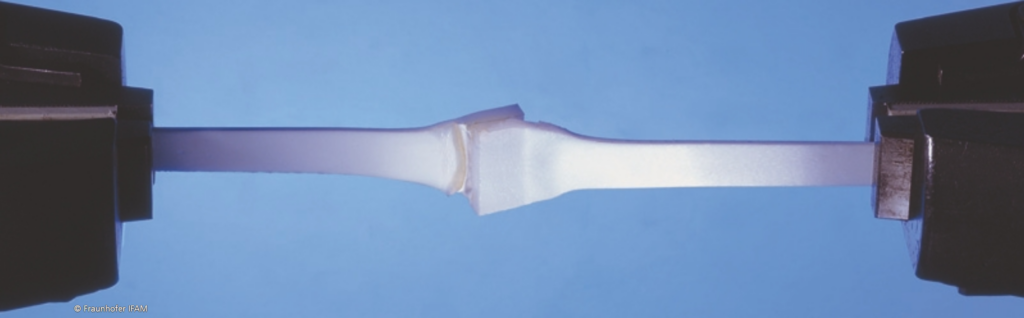

In the realm of structural engineering, the behavior of structural adhesives stands as a pivotal yet complex enigma. These polymeric materials provide the cohesion and longevity of a wide array of engineered structures, from aircraft to automotive components. Their primary challenge lies in predicting their fatigue life, especially under the influence of cyclic loads. Such calculations are challenging and demanding in terms of precision and efficiency.

Structural adhesive joints are rather complex; they consist of an adhesive (typically a polymer) and two substrates, which can consist of metal, polymer or composite materials. As one can imagine, this inherent complexity makes it challenging to assess their fatigue performance, let alone to optimize it in a next step.

While physics-based models offer the highest accuracy for analyzing these joints, they require meticulous parameter calibration for every new adhesive. For example, consider a fatigue test on a structural adhesive joint with 10 million cycles at a frequency of 10 Hz. These tests are demanding and time-consuming, taking over 10 days to complete. Adding to the challenge is the need for numerous data points to construct a comprehensive fatigue design curve, a fundamental aspect of structural analysis. Given the need to optimize both efficiency and accuracy, engineers and researchers need and pursue innovative solutions.

One path to solution is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into materials science. Recognized for its ability to address complex problems through learning from existing knowledge, AI provides a promising avenue for structural modeling by generating mathematical expressions that capture the interplay of various parameters. We expect that this rationale also applies to the structural modeling of the fatigue behavior of structural adhesive joints, which is the subject of our ongoing research.

However, the application of AI/ML in materials science often faces a practical challenge – the fact that in reality there is restricted availability of / access to data that is suitable to train the AI/ML algorithms. This challenge is partly being addressed by commendable initiatives to establish repositories and marketplaces for materials data, but in practice, the availability of comprehensive data remains constrained.

The promise of hybrid models

Towards achieving a solution for such complex challenges, researchers are already exploring the previously uncharted territory of hybrid models [1], which represent the synthesis of data-driven AI and physics-based methodologies. These models strategically leverage data from heterogeneous sources, including peer-reviewed articles, technical reports and material databases. By exploiting similarities in material behavior within specific categories, these hybrid models have the potential to provide an adequate understanding of the fatigue response of structural adhesive joints.

Hybrid models stand out for their capacity to integrate domain knowledge, guiding the selection of pertinent features and minimizing the risk of overfitting—a common pitfall where a model becomes too closely tailored to the training data, impeding its adaptability to new datasets. For example, Physics-informed neural networks (PINNs) harmonize established physics-based relationships with AI, achieving a delicate balance between “big data, small physics” and “small data, big physics.” [3].

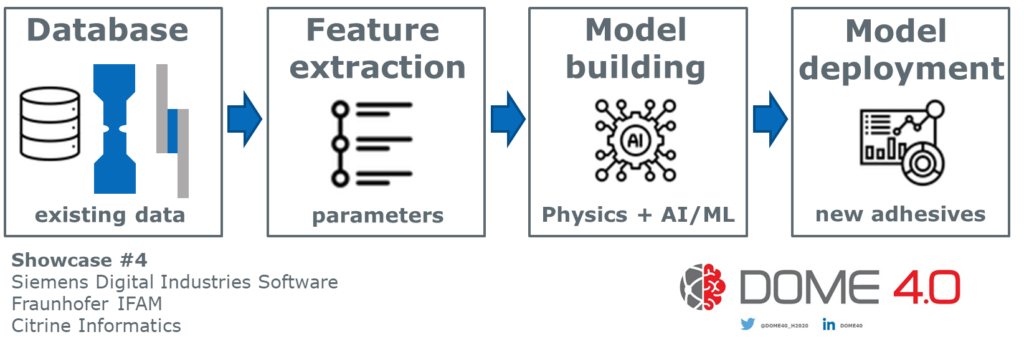

Showcasing hybrid modeling on the DOME 4.0 platform

In line with this innovative vision, Siemens Digital Industries Software and Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM are actively involved in the research project DOME 4.0 (Digital Open Marketplace Ecosystem 4.0). This project aims to establish a semantically enriched digital platform that seamlessly connects various materials data sources with numerous stakeholders, ensuring rigorous data transaction management to protect participant privacy. DOME 4.0 targets to revolutionize materials data exchange through efficient utilization of data for virtual materials engineering and product design, while fostering innovative business models rooted in cloud-based workflows. The technological innovations featured in this blog post are part of Showcase 4 within the DOME 4.0 project, which comprises a research collaboration between Fraunhofer IFAM, Siemens Digital Industries Software and Citrine Informatics.

This showcase exemplifies our commitment to revolutionizing materials selection and fatigue life prediction for adhesive joints. Leveraging the Citrine Platform [2], we seamlessly apply machine learning methods to integrate experimental datasets with physics-based modeling (based on stress concentration factors). This innovative approach not only significantly elevates the precision of fatigue predictions but also enables the precise selection of optimal adhesives for bonded structures, factoring in various material and geometrical properties, as well as usage conditions.

As ongoing research endeavors in this domain continue to evolve, it is evident that hybrid models have a promising future. Their potential is to blend empirical data-driven insights with the sound principles of physics, offering a path to better understand and fortify the behavior of complex structures, including structural adhesive joints. Engineers, scientists and industry professionals are all at the forefront of this new era, contributing to make such hybrid models fit-for-purpose for engineering design challenges now and in the future.

We hence invite all active on the tangent plane between materials science and engineering (and all those interested and curious about the potential) to be informed on the current status and to stay tuned for future advancements of hybrid modeling. And we hope that when you see a structural adhesive joint the next time, you’ll see it with a revitalized appreciation for the science supporting its strength and reliability.

For additional insights, be sure to also explore the Simcenter blogpost “Materials informatics accelerates customer tailored composite material design” (covering Showcase 9 in the DOME 4.0 project, which is also enabled by the Citrine Platform).

Acknowledgement

Siemens Digital Industries Software (DI SW) and Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) acknowledge the support of the European Commission for the Horizon 2020 Research and Innovation project “DOME 4.0” (see https://dome40.eu/), with Grant Agreement No. 953163, coordinated by CMCL.

This blog post reports the technology innovation status of Fraunhofer IFAM, Siemens DI SW and Citrine Informatics for Showcase 4 “Structural adhesives: Fatigue behaviour” in DOME 4.0.

References

[1] Fernandes, Pedro Henrique Evangelista, Giovanni Corsetti Silva, Diogo Berta Pitz, Matteo Schnelle, Katharina Koschek, Christof Nagel, and Vinicius Carrillo Beber. “Data-Driven, Physics-Based, or Both: Fatigue Prediction of Structural Adhesive Joints by Artificial Intelligence.” Applied Mechanics 4, no. 1 (March 8, 2023): 334–55. https://doi.org/10.3390/applmech4010019.

[2] Citrine Informatics, “What is Materials and Chemicals Informatics?”, Citrine Website, 2023.

[3] Karniadakis, G.E., Kevrekidis, I.G., Lu, L. et al. Physics-informed machine learning. Nat Rev Phys 3, 422–440 (2021). https://doi.org/10.1038/s42254-021-00314-5