Executable Digital Twins (xDTs) will continue to dominate engineering in 2024. While the previous blog post explains the 5 reasons why, this blog post will get practical and dive deeper into how xDTs can be embedded into physical testing. We will look at how Simcenter Testlab Neo 2306 helps you to both correlate the predictions of xDTs and calculate engineering performance metrics with ease. xDTs simulating different types of physics such as mechanics, hydraulics, electrics can be used to cover the needs of different industries. So let’s proceed to experience how xDTs bring together the best of the simulation world and the physical testing world for all your Model-based System Testing needs.

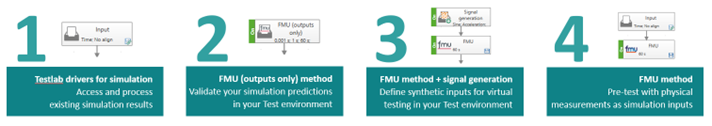

The 4-step process

Simcenter Testlab Neo 2306 brings forward a new 4-step process for efficiently embedding xDTs into physical testing solutions. This process is meant to assist you in gradually moving your Digital Twins from their authoring simulation software to the physical testing software (Simcenter Testlab Neo in this case). Once inside the physical testing software, the Digital Twins can be executed (a.k.a Executable Digital Twin) to correlate their prediction, calculate engineering performance KPIs or augment physical measurements. This process helps you build trust that your Executable Digital Twins are providing you with the valuable system predictions you are looking for.

The 4-step process takes place in Simcenter Testlab Neo Process Designer. This powerful post-processing tool allows the calculation of engineering KPIs for both your simulation and test data. This enables easy correlation or extension of datasets from both xDTs and physical tests in 1 environment and with 1 set of processing parameters. Let’s dive together into how each step is done in practice.

Schematic of the 4-step process showing the methods to be used in Simcenter Testlab Process Designer.

Step 1: Start by accessing the simulation data in the Test environment

The first step in validating your Digital Twin’s accuracy is to transfer the pre-existing simulation results to the Test environment (Testlab Neo). This allows you to calculate any engineering Key Performance Indicators (KPIs) and the correlation KPIs of your choice. Thanks to the Testlab Neo drivers for simulation, the simulation data from Simcenter Amesim, Simcenter 3D, and many other simulation software are directly accessible without any intermediate data conversion.