SOLIDWORKS Plastics comes pre-loaded with a wide variety of materials used for injection molding. The built-in database includes common polymers, metals, and coolants derived from data provided by different manufacturers. But what if a project in development uses a material that isn’t found in this list?

Good news! As with the SOLIDWORKS Material Database and the SOLIDWORKS Flow Simulation Engineering Database, there is the ability to create custom materials.

Accessing the SOLIDWORKS Plastics Material Database

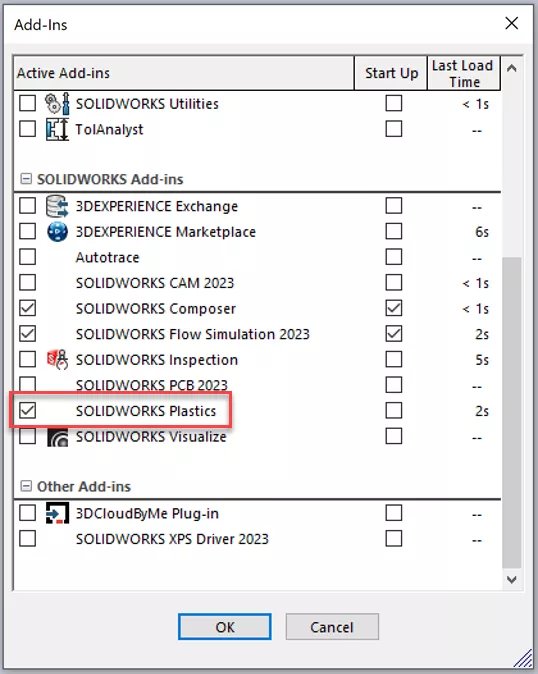

To access the SOLIDWORKS Plastics Material Database, turn on the Plastics add-in via Tools > Add-Ins… and check the box to the left of SOLIDWORKS Plastics.

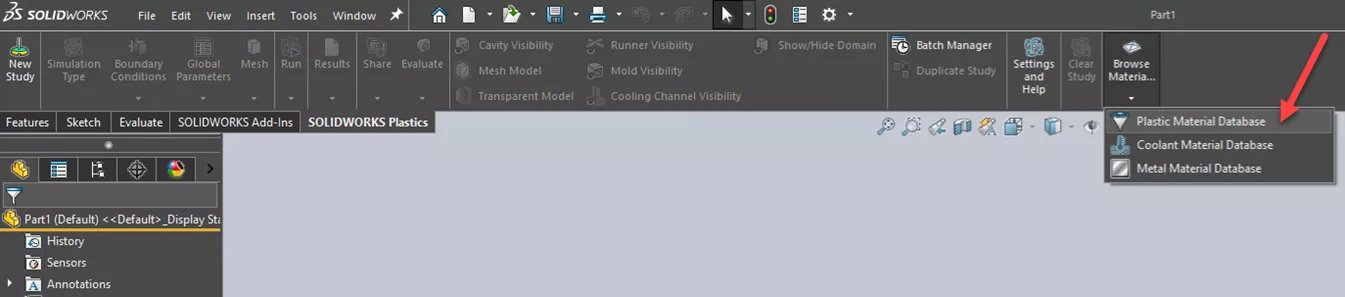

Then, go to the SOLIDWORKS Plastics tab in the CommandManager and click Browse Material Database > Plastic Material Database.

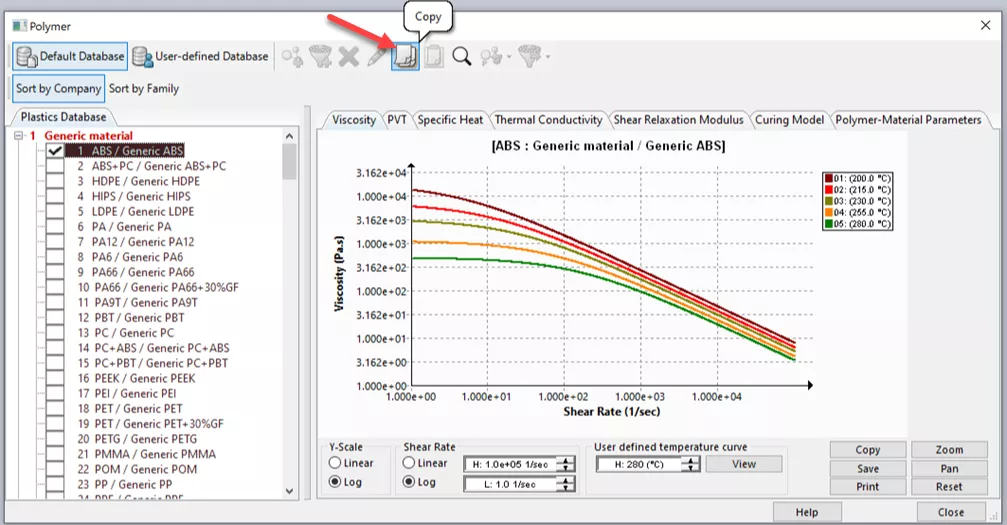

In the Plastic Material Database is the ability to sort by company or by material family. Each listed material in the Default Database has curves and tables that indicate its properties, including its viscosity, thermal conductivity, melt temperature, specific heat, etc.

These properties are not editable in the Default Database, so you must copy one and use it as a starting point for your custom material. Select one of the listed materials and click Copy to do so.

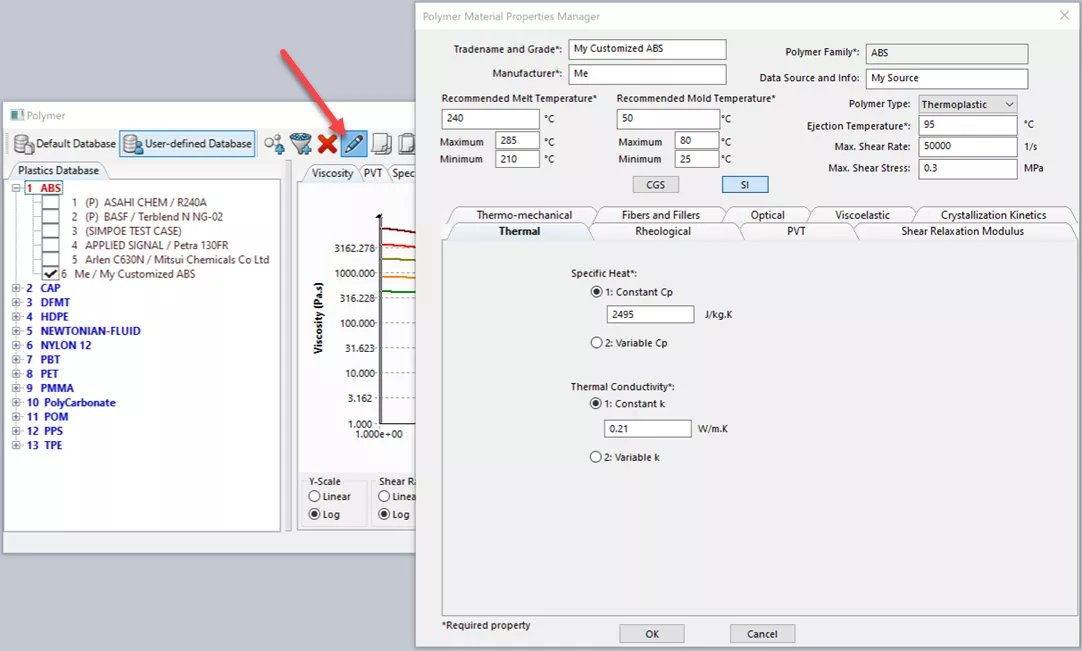

Then, switch over to the User-defined Database and click Paste. The material will automatically get pasted into the appropriate family.

Once the copied material is in place, click the Edit button to make any necessary changes so that the custom material is perfectly dialed in. Material properties can also be edited to match a supplier’s specifications. Make sure to give the material a new name to distinguish it from the material from which it was copied.

And that’s how to create a custom plastic material in SOLIDWORKS Plastics!

The same process can be applied to create custom materials in the Coolant Material Database and the Metal Material Database, which can be accessed via the Browse Material Database button on the SOLIDWORKS Plastics CommandManager tab.