CONTACT Software expands its open Elements platform for manufacturing operations management (MOM) with a new module for resource planning on the shop floor.

CONTACT Software expands its open Elements platform for manufacturing operations management (MOM) with a new module for resource planning on the shop floor.

CONTACT Elements for IoT provides no-code applications for asset management and the comprehensive digitalization of manufacturing that go far beyond the functionality of an MES and can be flexibly combined. Now, CONTACT Software has expanded its offer for the smart factory with a new app for staff scheduling.

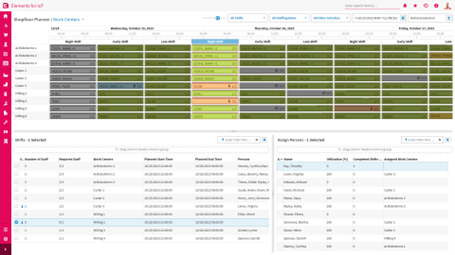

The asset-centric view shows which persons are scheduled for a specific workplace.

The Shopfloor Planner was developed in close collaboration with thyssenkrupp Dynamic Components. It significantly simplifies machine allocation in production and creates transparency. This enables companies to quickly respond to deviations from the plan, such as personnel shortages, to meet delivery deadlines and avoid costly penalties.

Transparent shift planning for the shopfloor

The Shopfloor Planner provides production managers with an overview of which team members are available, ill, or on vacation. Once planning is complete, it shows which persons are scheduled for each machine and shift and indicates whether setup processes or services are due. Filtering and color coding make it easy to see whether a shift is over- or understaffed.

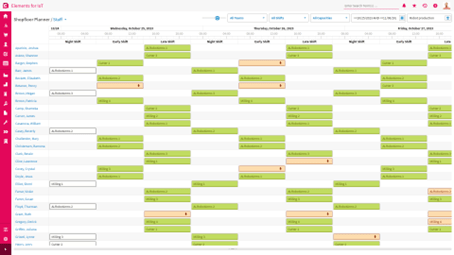

The people-centric view lists for each employee at which workplace he or she is scheduled. (Images: CONTACT Software)

Closing planning gaps quickly

Production managers can immediately see where action is needed if someone is absent at short notice. Elements for IoT lists the individuals with the right qualifications to close each planning gap. One look at their previous workload is enough for managers to identify a suitable replacement and prevent plant downtime.

Thyssenkrupp Dynamic Components is a leading automotive supplier of drivetrain components for combustion, hybrid, and electric motors. The company has been using CONTACT Elements for IoT for global production control at its ten manufacturing sites for a year now.

About CONTACT Software

CONTACT is the leading vendor of open standard software and an open-source pioneer for the product engineering process and the digital transformation.