We’re pleased to bring you the third installment of our What’s New in NX™ software series for the December 2023 release. Throughout the year, we’ll be shining the spotlight on new capabilities added to NX. In this blog, we’ll be looking at new functionality within surface treatments, and how you can implement these tools into your workflow.

NX Corrosion Analysis Indicator

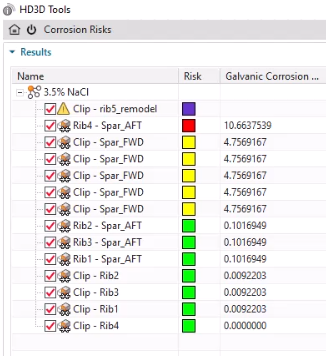

NX Corrosion Analysis is a new NX add-on module introduced in the December release of 2023 which is available through value-based licensing. This module provides corrosion analysis on component parts in an assembly based upon proximity and assigned materials and coatings.

You can use Corrosion Analysis to predict corrosion risk rate based on the galvanic properties of the assigned materials using the latest industry-approved methods. NX reports results both graphically and textually to inform designers in an easy to understand and comprehensive manner.

Key benefits to Corrosion Analysis

NX Corrosion Analysis Indicator provides a few important benefits. One advantage is the ability to evaluate potential corrosion issues early in the design phase. Doing this saves valuable time and resources, which you can allocate to other areas of focus.

Another benefit is that NX can identify any missing material and coating areas on your designs. This eliminates a need to manually check your parts and and assemblies, providing additional confidence during the production phase.

One other important benefit is that Corrosion Analysis helps ensure designs adhere to industry standards for corrosion modeling. This is an integral aspect of creating successful designs and models.

Where this fits with surface treatments

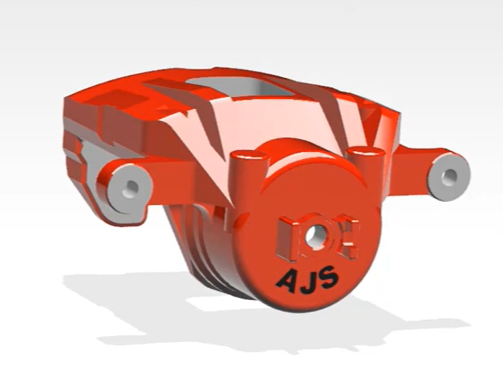

Overall, Corrosion Analysis Indicator provides a lot of value towards understanding how your parts and assemblies will hold up over time. This is a great tool to explore the impact your coating layers down stream. NX Coatings is a fully integrated application that allows specification of coatings for product design. This is also an add-on module that is available through value-based licensing.

In tandem with the new Corrosion Analysis tool, coating layers provide even more value. With NX Coatings, we can define regions with specific coating treatments, assign surface coatings with the NX material libraries, and even organize coatings into stacks. It is also easy to determine overall mass rollup with surface treatments, and add associated PMI .

Recent surface treatment Tips and Tricks

Over the last few weeks, we have released a series of Tips and Tricks videos on surface treatment workflows. These videos are a great place to begin if you’re new to using NX Coatings or Corrosion Analysis. These first three videos, show how to create or apply coating layers, investigate existing surface treatments, and document our coating layers through PMI and part drawings.

In the latest installment of the Tips and Tricks series, we can see exactly how to use the new NX Corrosion Analysis Indicator. From configuration settings, to understanding the graphic window, this is a great place to get started with checking your designs for durability and industry standards.