The word “generative” has certainly risen in popularity over the last couple of years. Most people probably jump to “generative AI”, which is usually understood to mean sitting in front of a computer, making a relatively simple request (often a text prompt), and – with no direct involvement in the generation process – receiving a complete output that matches that request, be it a piece of writing, an image, a song, or even a video. But what about in the design and engineering world? Can we do that? For SOLIDWORKS or CATIA users, it’s actually a two-part question:

-

- Can designers provide a limited, structured input to a program and get a complete geometric output? Yes – this is called “generative design”. It is not new, and it comes in many forms.

-

- Can you do it with AI? The answer here is also yes, but this technology is very new and just now reaching public availability in small increments.

In this article, we’ll introduce you to three forms of generative design – node-based design, parametric optimization, and topology optimization – and give you a sneak peek at the generative AI that’s coming to SOLIDWORKS in the near future.

Node-Based/Scripted Design

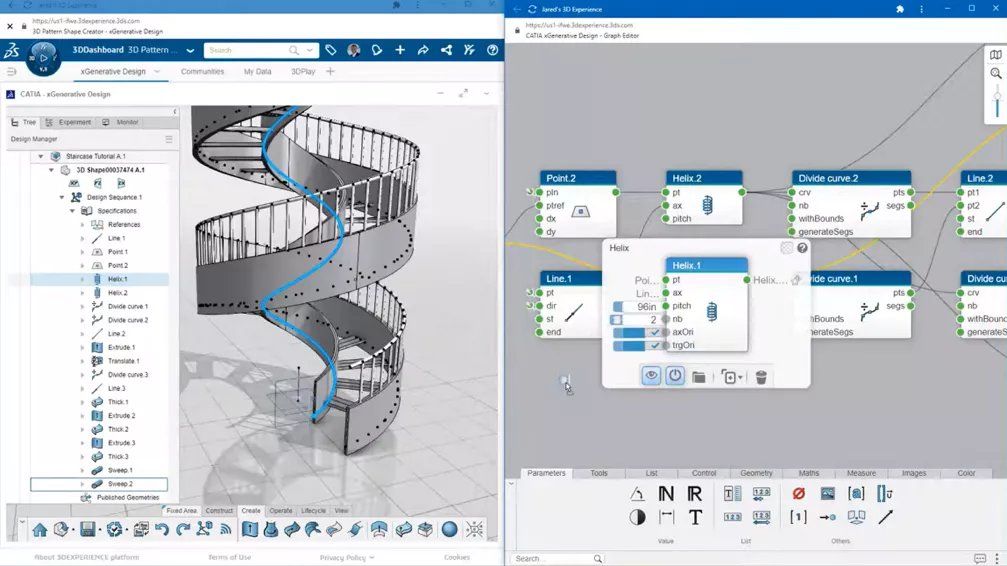

One of the newer generative design technologies takes a diagram- or node-based approach. This is similar to parametric 3D modeling, but instead of having to develop intricate formulas in a 3D environment, the interface is very clean and easy to navigate in 2D.

Chains of operation and data nodes create a full 3D model output. A simple change in a node could easily propagate a huge change across the entire model, the key advantage of this modeling approach. Click to watch our tutorial on how to create a staircase with this method.

If you’ve seen any modern looking designs, then you’ve probably seen the benefits of node-based design, also known as “visual scripting”, and did not even know it. Some examples include the textures on a computer mouse, earpad cushions on headphones, the front grill on almost any automobile, architectural buildings, or any product where the patterns must be controlled and are typically complex.

The primary advantage of a node-based modeling environment is when you really need to turbocharge patterning or batch-like workflows. It produces large amounts of complex output and can make large-scale changes to a model with relatively little clicking around. Script-based modeling is also completely nondestructive and quickly replicable – it doesn’t consume any features and provides access to entity values all over the model to help build robust and fast patterns.

Click to watch this CATIA Design Talk – with demonstration – on node-based design/visual scripting.

GoEngineer offers two Dassault Systèmes products for this kind of generative design – CATIA Visual Script Designer for node-based modeling on your local machine, and 3D Pattern Shape Creator for node-based modeling in a fully 3D, cloud-powered web app. Both products are on the 3DEXPERIENCE Platform and based on the CATIA modeling engine, so you can easily integrate their output with your primary SOLIDWORKS or CATIA solution, and then build on top of those models.

Parametric Optimization

In the past, designers would typically design a product and then run a simulation on the model to see if the part or assembly would be able to support the required load(s). If the simulation were to predict failure, the designer would then change the model and rerun the simulation to verify the fix was successful. This process of redesign and retest can be automated and scaled in what is called a “parametric study”. The user input is a desired simulation result and what CAD parameters may be altered, and that redesign-retest loop iterates parametric changes until the simulation is a success.

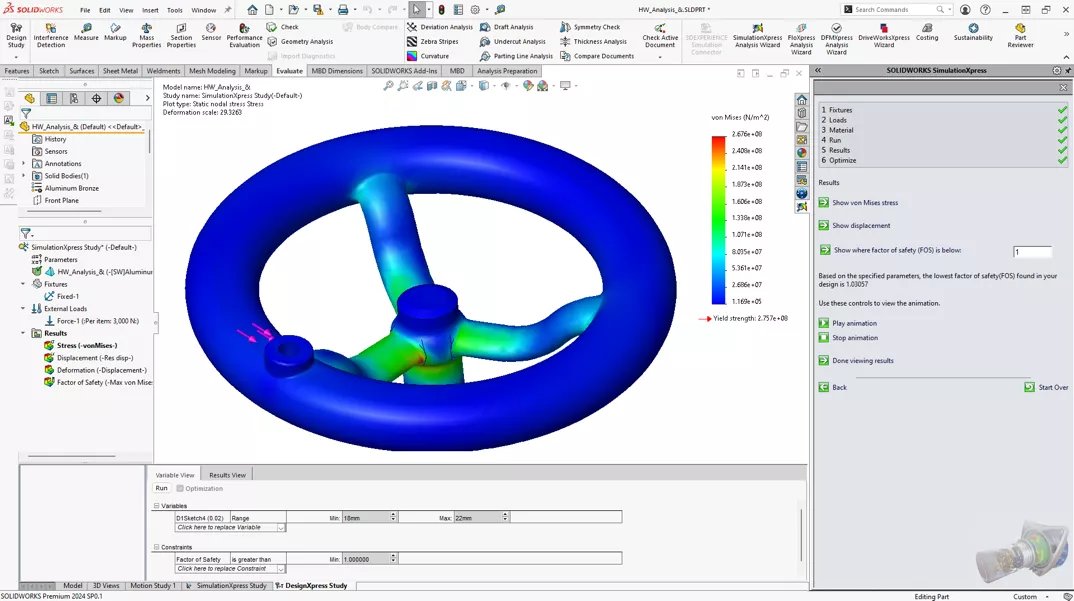

A SOLIDWORKS SimulationXpress example of a design study.

You need tools to run these studies and interpret the results. GoEngineer and Dassault Systèmes offer several tools covering a wide range of sophistication. At the most basic level, if you’ve taken SOLIDWORKS Essentials class, you might recall using SimulationXpress (built into SOLIDWORKS Standard), where you ran a parametric simulation with the handwheel and set a dimension to alter in order to reach a certain factor of safety.

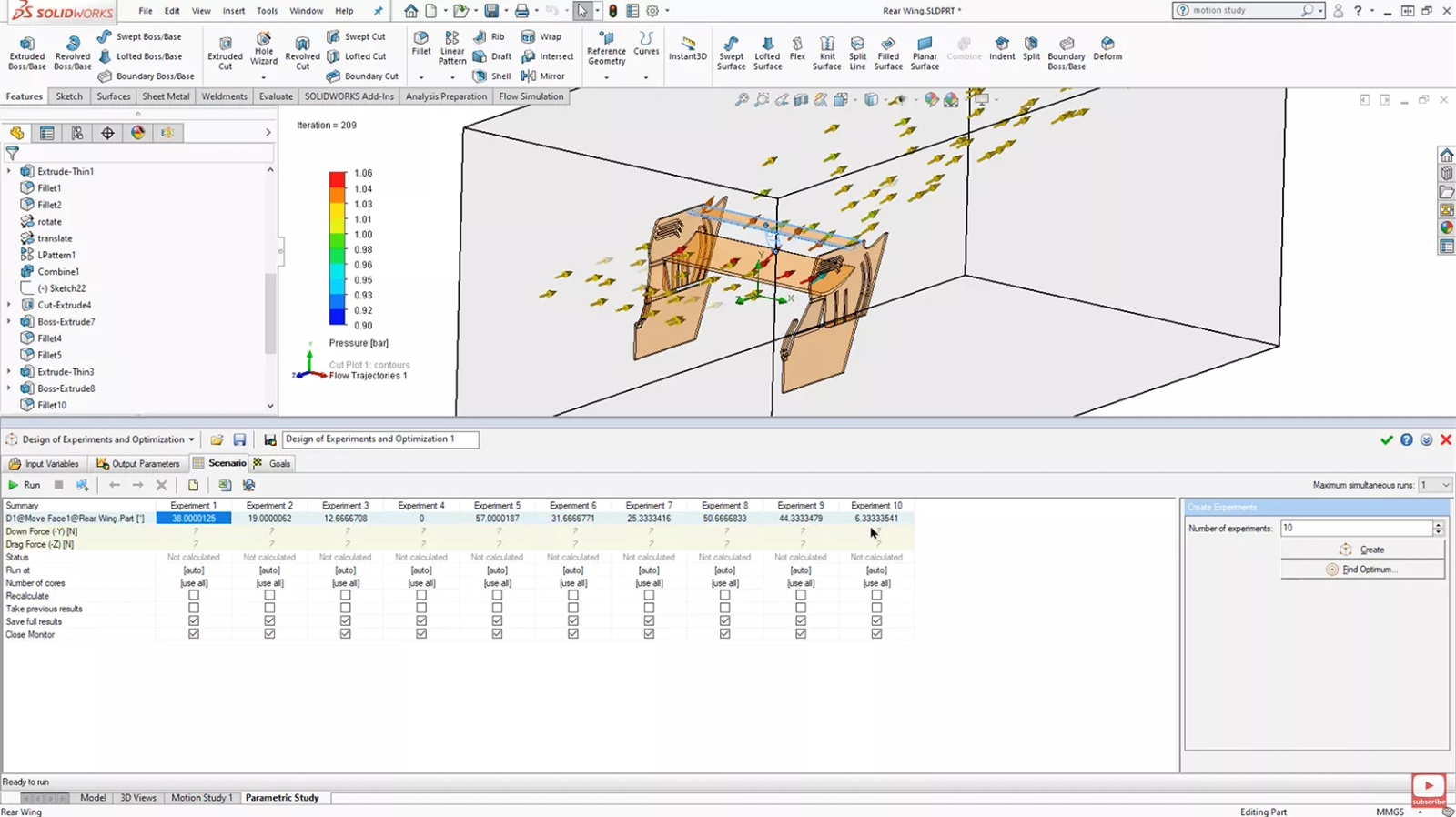

Setting up a CFD design study in SOLIDWORKS Flow Simulation.

For a little more power, you have SOLIDWORKS Simulation Professional, which includes more tools for optimization and the Load Case Manager, which makes it easy to run multiple load cases, add combinations of cases, and track goals. SOLIDWORKS Flow Simulation also includes easy-to-use, basic parametric design study capabilities for CFD. On the electromagnetics side, CST Studio Suite (an electromagnetics simulation offering) provides a parametric optimization process using its SOLIDWORKS CAD link.

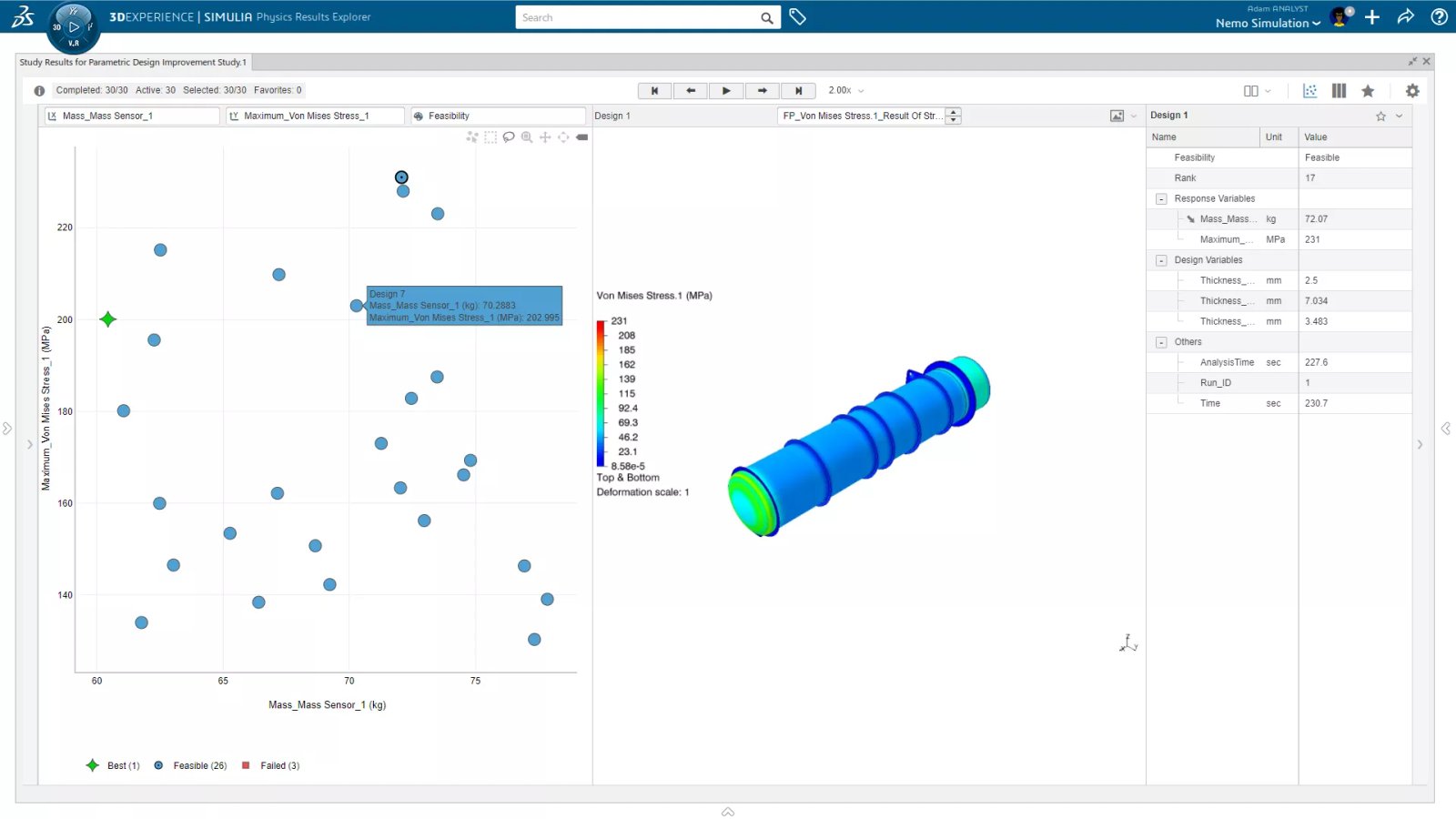

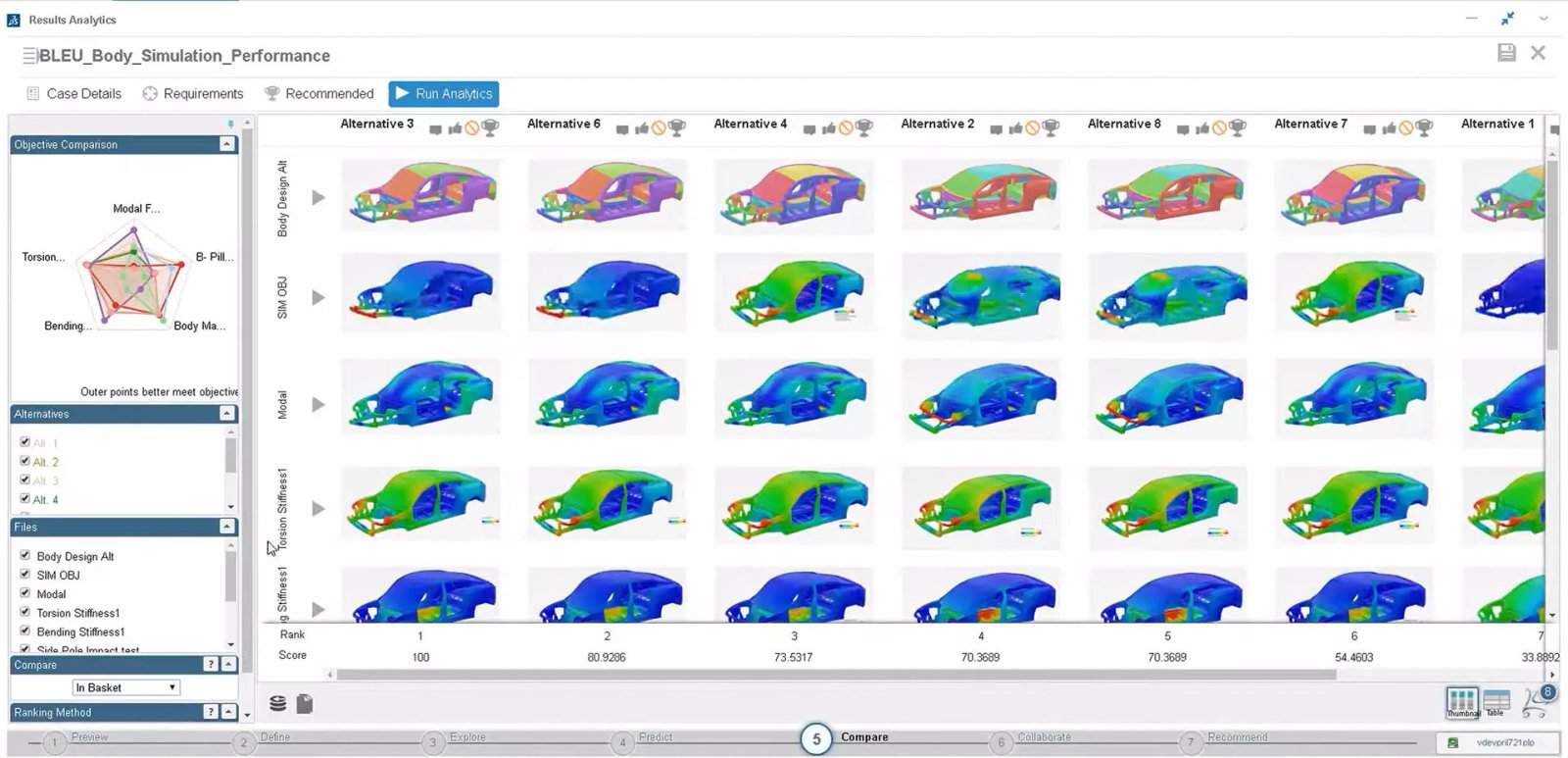

A design study of 30 alternatives using the optimization capabilities that come with the 3DEXPERIENCE STRUCTURAL FEA solution.

When you upgrade from SOLIDWORKS Simulation to 3DEXPERIENCE STRUCTURAL for your mechanical FEA, optimization studies get even better. Not only do you get the more robust Abaqus solver, you get cloud compute capabilities so you can very quickly run large amounts of design variations. You also get new study review tools that are powerful enough to handle the increased scale of design variables and simulation results.

Evaluating several design alternatives tested against several performance criteria using 3DEXPERIENCE postprocessing tools.

At the highest end is SIMULIA Isight and 3DEXPERIENCE Multidisciplinary Optimization (whose core functionality is based on Isight). Isight is a highly open-ended process creation framework for exhaustively optimizing product designs using the wide array of included numerical optimization methods and design-of-experiment (DOE) techniques. Isight can incorporate many other tools in these optimization processes, including commercial CAD/CAE software, internally developed programs, and Excel spreadsheets.

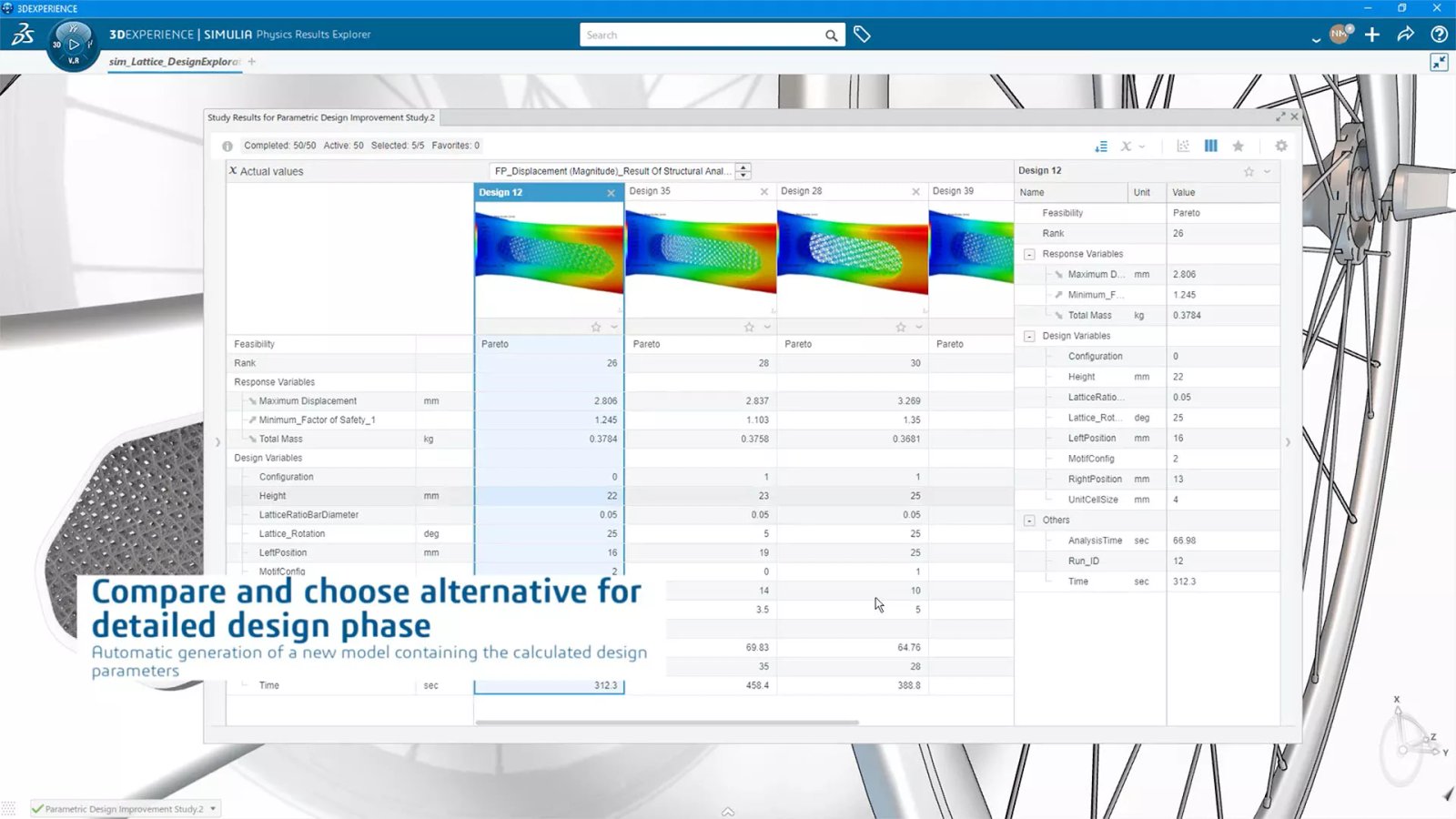

By combining 3DEXPERIENCE Lattice Designer with 3DEXPERIENCE STRUCTURAL’s optimization tools, not only can tremendous amounts of design and simulation labor can be automated, a better design can be achieved.

3DEXPERIENCE Multidisciplinary Optimization offers Isight’s capabilities (including third-party integration) on the 3DEXPERIENCE Platform and in a more modern 3D interface. The 3DEXPERIENCE version also makes the vast amount of optimization data more accessible to others and provides process templating tools. When testing design alternatives in the thousands with these tools, the sky is the limit.

Topology Optimization

When design constraints and load requirements pile up, “overdesign” can quickly become the only practical solution for a human designer. These overweight parts increase costs and introduce their own structural issues. From such a starting point, the typical modeling and simulation process for improving that design is very tedious and incremental. This is why we have tools for topology optimization.

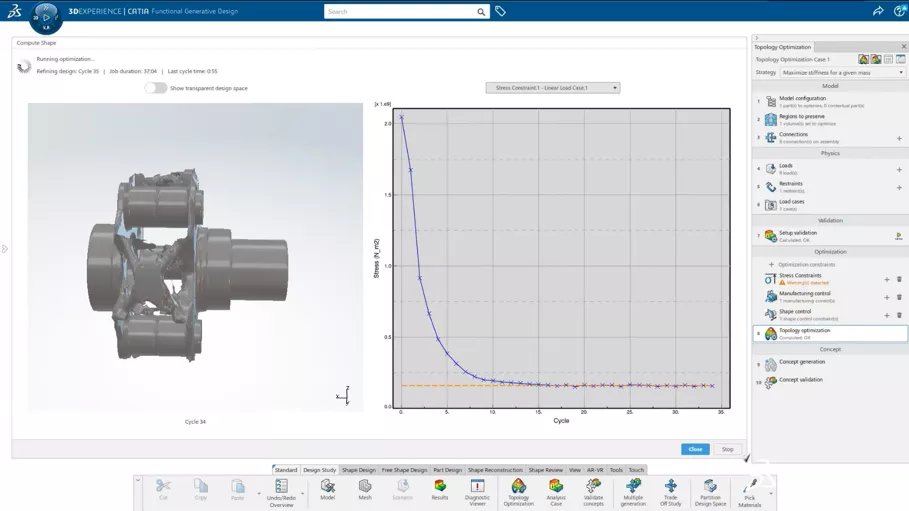

Topology optimization is a technique that uses simulation of loading scenarios against design, manufacturing, and performance requirements in order to create a design from nothing that accounts for everything all at once with minimal additional mass. You provide your design requirements (including a solid block of design volume to work within), set up the necessary simulations, and the topology optimization tool will conduct simulation and redesign iterations until it achieves the target. It is a highly automated pathway to a lighter, stronger, and more efficient design. Like parametric optimization, there are levels of topology optimization tools available from within SOLIDWORKS, proceeding through desktop SIMULIA, and up to the 3DEXPERIENCE Platform.

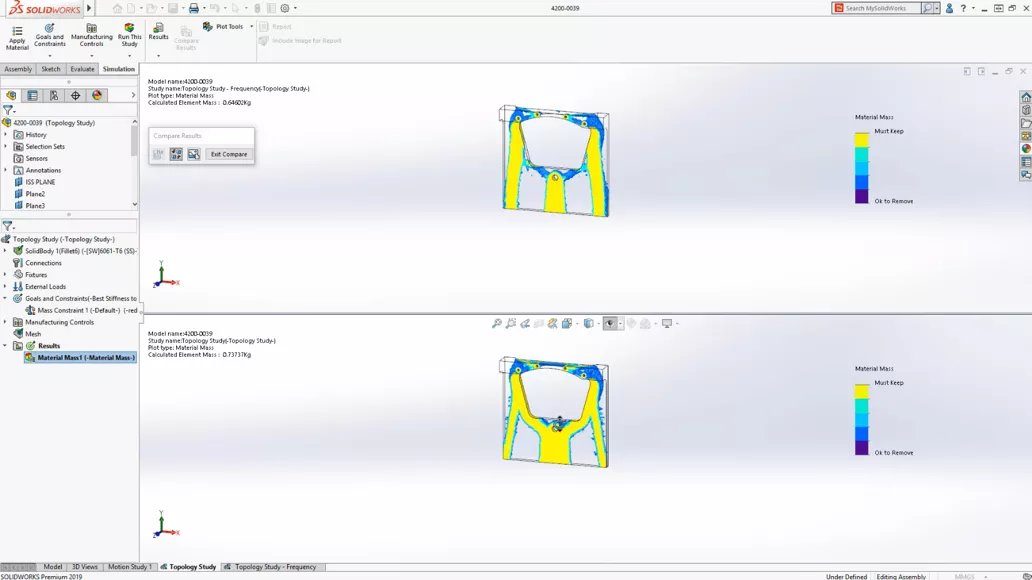

SOLIDWORKS topology optimization restricts material to where stiffness is needed.

SOLIDWORKS Simulation Professional is the start of the topology optimization offerings, working on single parts and with linear static and frequency analyses. You indicate a design space, set manufacturing constraints and FEA load cases, and then a goal – minimize the mass, maximize the stiffness-to-weight ratio, or minimize the maximum displacement. The design space is whittled away until it meets the goal as efficiently as possible. You can bring the final shape back to 3D CAD for proper modeling.

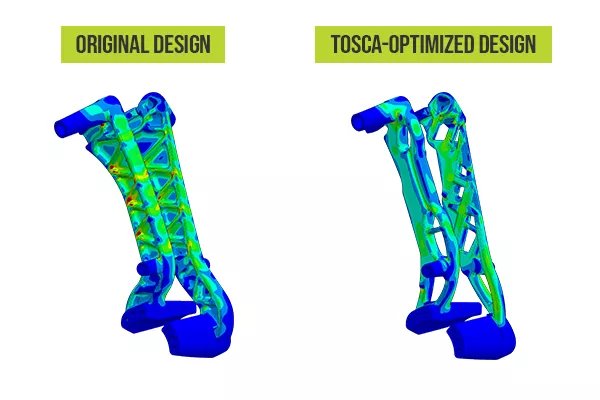

The GoEngineer simulation team used Tosca to simultaneously optimize two part designs in an assembly, improving performance and reducing weight.

The next level up is SIMULIA Tosca Optimization Suite, which, like Isight, is included in desktop Abaqus licensing. Tosca is very open-ended and easy to use, but better integrated with the simulation side than the design side. It can leverage multiple FEA codes (including third-party ones), even in the same optimization task. That means designs can be optimized against a combination of all kinds of analyses, including sophisticated multipart nonlinear analyses, explicit dynamic, fatigue, etc.

Topology optimization is not just for 3D printing. All it takes is the appropriate manufacturing constraints.

Tosca also allows you to optimize assemblies (as opposed to just single parts) and provides additional optimization goals beyond mass and stiffness. Specialized forms of topology optimization like shape and bead optimization are also available in Tosca.

Topology optimization using the setup wizard on the 3DEXPERIENCE Platform.

The 3DEXPERIENCE GENERATIVE DESIGN line of solutions offers Tosca-based optimization on the 3DEXPERIENCE Platform in a modern user interface and with direct CAD integration. The other unique and major advantage to this solution is the cloud compute capability, which can compress computation time severalfold. This solution comes in good-better-best packages for different user profiles and with varying levels of functionality regarding the analysis and optimization capabilities.

If your designs include fluidics, then Tosca Fluid Optimization and 3DEXPERIENCE GENERATIVE DESIGN can create flow-optimized designs for you as well. These solutions work in much the same way as the structural versions, just with a CFD code like 3DEXPERIENCE FLUIDS. They will generate channel shapes that minimize pressure drops and preserve the mass flow rate.

Hint of the AI Future of Design

AI is being integrated into every facet of our lives, including iPhone face ID, social media and news feeds, grammar checking email, Google searches, voice-to-text, banking fraud protection, and saving lives with analyzing medical images for detecting cancer.

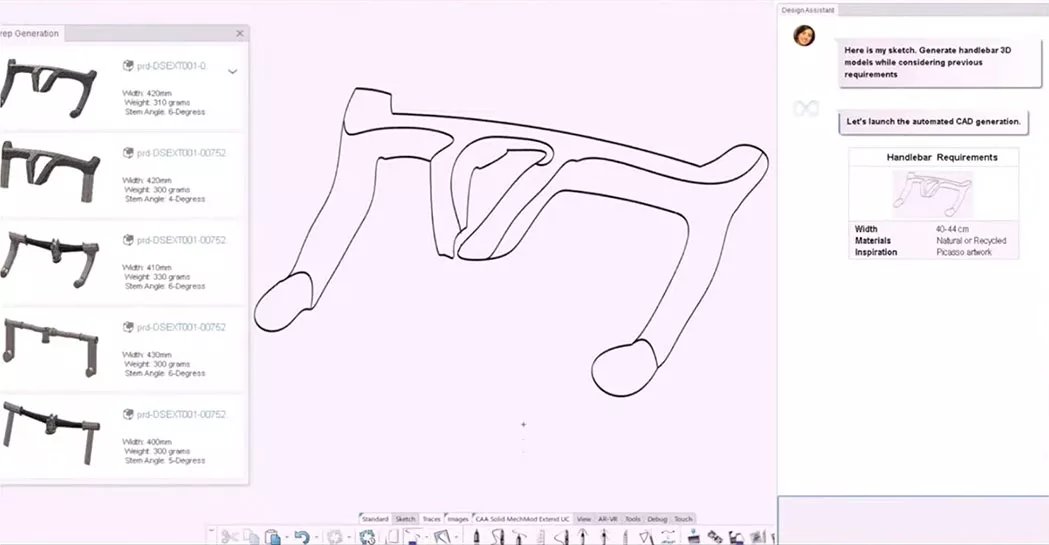

A sneak peek at the Magic SOLIDWORKS generative AI interface for CAD.

Dassault Systèmes has been working on AI-automated model generation (and simulation) for over ten years, and at 3DEXPERIENCE World 2024, we got to see an amazing text-and-sketch interface of Magic SOLIDWORKS as it automatically generated 3D models based off of a simple bicycle handlebar sketch and some design criteria. The AI created multiple b-rep models, allowed the user to pick something closely resembling their intent, and then placed it in the correct location on the full bicycle assembly. Next, the AI design assistant used simulation to refine the design to make sure it was the lightest and strongest design.

The SOLIDWORKS team is also working on getting AI to perform daunting or tedious tasks like adding hundreds of nuts, bolts, and washers automatically to models, automatic image-to-sketch, and automatic drawing creation. At 3DEXPERIENCE World 2024, SOLIDWORKS also showed off the ability to train AI-powered CAD generation based on a data set of a single class of products, in this case, furniture, which they deemed their “first generative modeling tool that is in production”.

Conclusion

The term “generative design” encompasses many products and processes that the SOLIDWORKS customer can access, from node-based design to parametric and topology optimization to generative AI. Some of these tools have been around for years and are quite robust, while some are new or still in development. What they have in common is that they all have the potential to do tremendous amounts of design work with relatively little input from the user.

These tools will not replace core 3D CAD, but in the right hands, they can have a multiplicative impact on efficiency and quality, especially as you move up their product stacks. They are generally at their strongest with the cloud compute power of the 3DEXPERIENCE Platform, which will only become more true with the continuing advancement of AI.