Manufacturing organizations are always looking for new ways to optimize operations and cut costs. Ongoing technological advances and improved process methods are making this easier and easier. Unfortunately, manufacturing organizations can sometimes be slow to take on new approaches—and this inability to leverage new methods leaves companies eating the dust of their competitors.

Model-based product development (MBPD) is one of those methods. It builds on the foundation of model-based definition (MBD) and pushes organizations to achieve a full model-based enterprise (MBE) vision.

Model-based product development is the next iteration of model-based definition and is helping organizations realize their vision for a model-based enterprise.

What Is Model Based-Product Development?

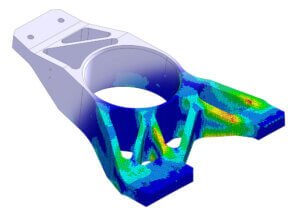

Model-based product development is the process of using native CAD models throughout the entire product development cycle. Using CAD models in this way drives a digital thread through the product lifecycle, making it easier to iterate and perfect designs. The method leverages modern technologies such as simulation and electrical routing to support all types of design, including industrial design, tooling design, manufacturing process development, and more.

Model-based product development uses native 3D CAD files throughout the product lifecycle— from ideation all the way through retirement.

Where Did Model-Based Product Development Come From?

Model-based product development was derived from model-based definition, which replaced 2D drawings with annotated 3D models that contain all the associated data elements needed to define products. Model-based definition has gained major traction in the industry as organizations face global competition, increasing product complexity, and fluctuating customer demand.

What Is the Future of Model-Based Product Development?

The future vision is a fully model-based enterprise that uses model-based definition across all processes from commission, operation, service, and decommission of a project.

There is still a missed opportunity here for many organizations. Engineering teams have made great progress with 3D CAD, but many have failed to take the leap into a model-centric approach to product development.

Taking a model-based product development approach that uses a unified platform and CAD model aligns progress throughout the entire engineering cycle.

It’s Time to Implement an MBPD Strategy

With this goal in mind, model-based product definition should be a top strategic goal for all manufacturing businesses. This approach requires modern 3D CAD tools that successfully integrate design, optimization, and build to evolve the digital thread. Collaborators building upon a single 3D model work more efficiently across the design process.

Get Started Building Your Digital Thread

Organizations require modern tools that support advanced 3D CAD modeling and leverage the benefits of a digital thread. Creo from PTC has all the tools teams need to achieve their model-based enterprise vision.

The latest release of the leading CAD platform includes:

- Real-time simulation

- 3D and parametric modeling

- Collaboration tools

- Composite design tools

- Design for electrification and ergonomics

- Support for additive and subtractive manufacturing

- . . . and more