joe

Guest

Hello

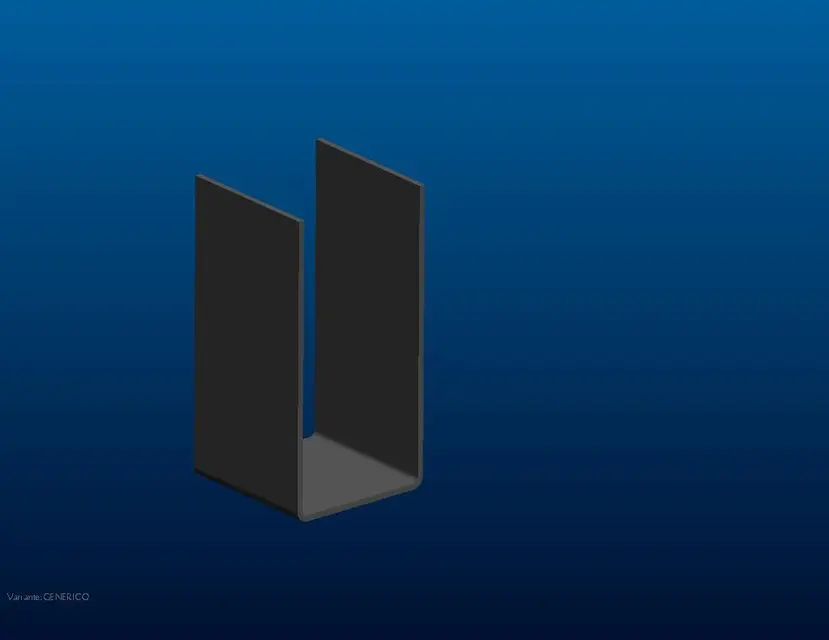

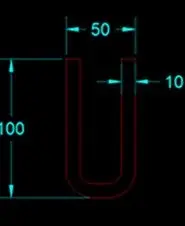

I have to draw with autocad 2011 a plate of mm 10 thick folded with u shape of size mm 100 x 50 x 100, please tell me how do I calculate the exact bending radius to have the precise development according to which to use the material with the right length?

I have to draw with autocad 2011 a plate of mm 10 thick folded with u shape of size mm 100 x 50 x 100, please tell me how do I calculate the exact bending radius to have the precise development according to which to use the material with the right length?