dandao

Guest

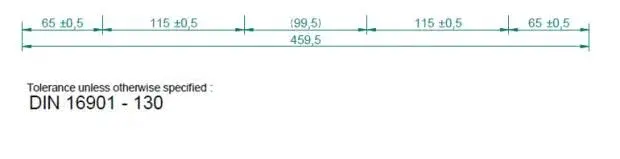

hi to all,I have the following dilemma:I have a particular printed in polypropylene and the customer tells me that they are out of tolerance with the quota 459.5 mm that turns out 461.3 mm and indicates me as field of tolerance + or - 0.7 mm

the design at that quota does not bring tolerance, but a reference standard that is the din 16901 - 130

consulting the norm according to me tolerance and + 0 - 1.5 mm x lengths ranging from 400 to 500 someone can confirm it?

this blessed incriminated quota (459.5 mm) and formed by 5 subquotes (see attached image) of which 4 with tolerance + or - 0.5 mm therefore the field should be + or - 2 mm

conclusion:

according to the customer the quota can go from 458.8 mm to 460.2 mm

according to me (checking the norm) the quota can go from 458 mm to 461 mm

with the sum of subquote tolerances the quota can go from 457.5 mm to 461.5 mm

Can someone tell me the right solution?

Thank you all and I apologize x this very long post

the design at that quota does not bring tolerance, but a reference standard that is the din 16901 - 130

consulting the norm according to me tolerance and + 0 - 1.5 mm x lengths ranging from 400 to 500 someone can confirm it?

this blessed incriminated quota (459.5 mm) and formed by 5 subquotes (see attached image) of which 4 with tolerance + or - 0.5 mm therefore the field should be + or - 2 mm

conclusion:

according to the customer the quota can go from 458.8 mm to 460.2 mm

according to me (checking the norm) the quota can go from 458 mm to 461 mm

with the sum of subquote tolerances the quota can go from 457.5 mm to 461.5 mm

Can someone tell me the right solution?

Thank you all and I apologize x this very long post