You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

meccanicamg

Guest

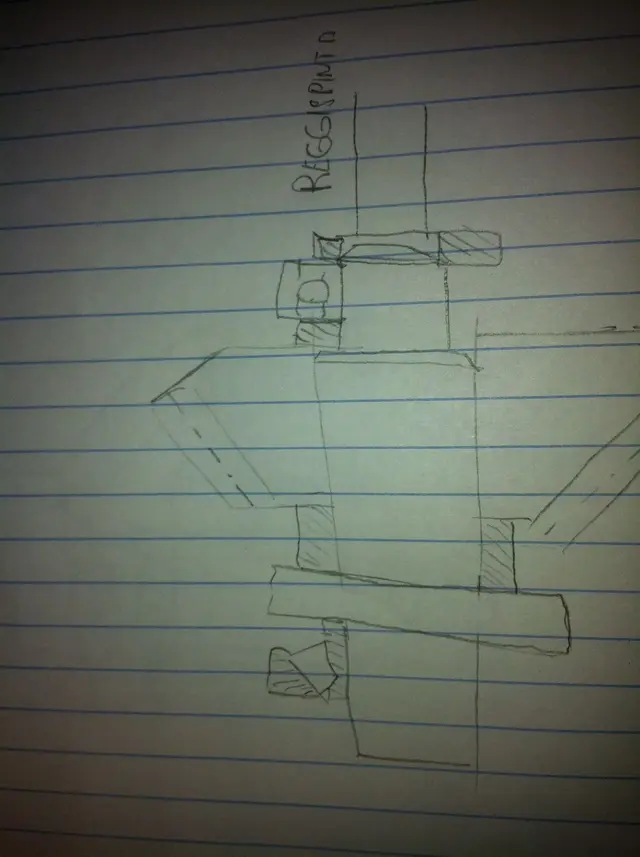

that I remember the exit tree is up and down no right and leftin the exit shaft I put the braces on the right of the wheel and on the left I have to put a radial bearing to compensate for the spins

is it correct?

to prevent that I still do not have the right knowledge to choose the bearings.

meccanicamg

Guest

and on the other side what is there? You can't do a groove with a cylindrical part of the same diameter on one side... The wheel must be threaded.Tell me if the mating with the scene is fine

to the right the channel I made it finish first

xxi

Guest

then high I put a conical roller bearingthat I remember the exit tree is up and down no right and left

down one ball and double effect braces

meccanicamg

Guest

check that the double brace can hold radial load, otherwise both bearings should be revised. look on skf!!then high I put a conical roller bearing

down one ball and double effect braces

xxi

Guest

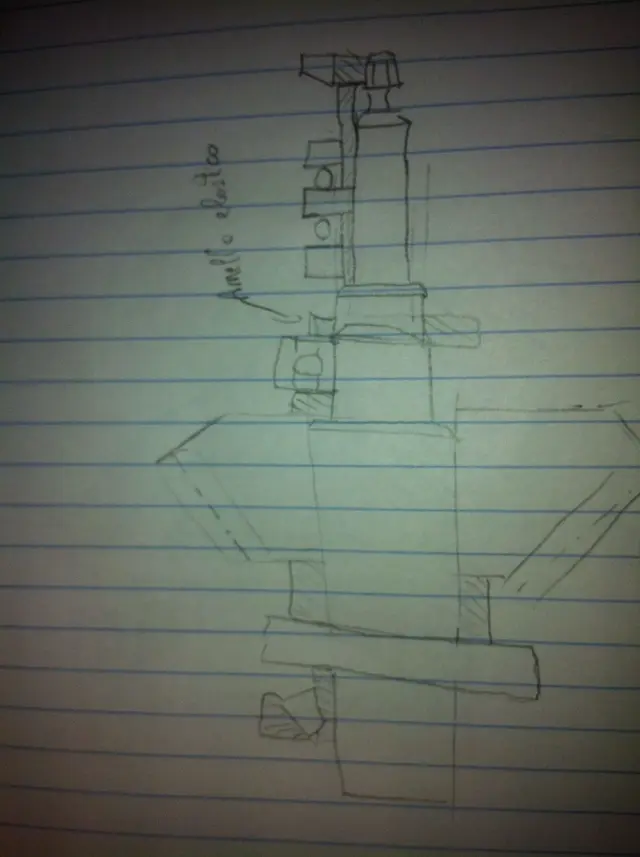

Guy sewing!and on the other side what is there? You can't do a groove with a cylindrical part of the same diameter on one side... The wheel must be threaded.

Attachments

meccanicamg

Guest

ah you put the short spacer sticking to the c...lo :finger: Okay.Guy sewing!

xxi

Guest

I didn't understand that.check that the double brace can hold radial load, otherwise both bearings should be revised. look on skf!!

and however the double-acting braces cannot hold radial load.

meccanicamg

Guest

is Italian. If it's a biaxial brace, I don't know how much it is to keep radial. if the tree you keep driving it only behind with a conical and front only axial you have that the tree runs out on the first half of a treeI didn't understand that.

and however the double-acting braces cannot hold radial load.

xxi

Guest

correct me if I'm wrong!ah you put the short spacer sticking to the c...lo :finger: Okay.

Attachments

meccanicamg

Guest

Okay, but then you don't need the tilted roller bearing anymore. There's that thing that costs a patrimony and it just doesn't help.correct me if I'm wrong!

xxi

Guest

ahahahh and what do I put in his place?Okay, but then you don't need the tilted roller bearing anymore. There's that thing that costs a patrimony and it just doesn't help.

another radial ball?

meccanicamg

Guest

Don't you think it's better?ahahahh and what do I put in his place?

another radial ball?

xxi

Guest

and then the trick lies in balancing the axial and radial forces or according to the function that the shaft will have to perform, are the suitable bearings chosen?(from the point of view of the loads).ahahahh and what do I put in his place?

another radial ball?

xxi

Guest

I say yes!Don't you think it's better?

snaroz

Guest

bearings that are on the exit shaft do not necessarily have to be different. for example I put two simple radial ball bearings, so much the whole axial load is "absorbed" by the braid.then high I put a conical roller bearing

down one ball and double effect braces

xxi

Guest

and you didn't lock the outer ball bearing tracks, with the right case? ?bearings that are on the exit shaft do not necessarily have to be different. for example I put two simple radial ball bearings, so much the whole axial load is "absorbed" by the braid.

snaroz

Guest

No, only the inner ring of the bearings blocked. external ones are naturally in their home, but they are not blocked axially.and you didn't lock the outer ball bearing tracks, with the right case? ?

meccanicamg

Guest

if it were not so during the thermal expansion of the shaft, this stretches and goes to axially preload the radial bearings bringing them early to the end of their life. only the biaxial bearing must bear such load.No, only the inner ring of the bearings blocked. external ones are naturally in their home, but they are not blocked axially.

xxi

Guest

Tell me what brake this reducer is and where am I wrong? ?

Thank you.