Simo91

Guest

Bye to all,

sincerely I am a little acerbo in the pneumatic systems (small systems with Boolean logic, but beyond that zero), and therefore I look for advice:

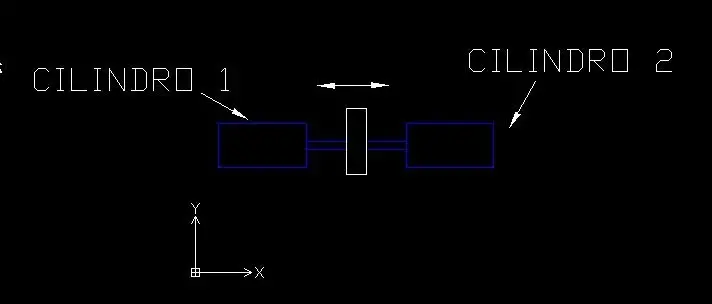

My problem is to make the system "dynamic" in the photo (Annex), in fact placing 2 identical opposing cylinders you create the balance in the middle.

an idea (if feasible) is to control in place the 2 stems of the cylinders, so as to make it dynamic, but it is not propius that fishes plow:frown:

Thank you in advance

sincerely I am a little acerbo in the pneumatic systems (small systems with Boolean logic, but beyond that zero), and therefore I look for advice:

My problem is to make the system "dynamic" in the photo (Annex), in fact placing 2 identical opposing cylinders you create the balance in the middle.

an idea (if feasible) is to control in place the 2 stems of the cylinders, so as to make it dynamic, but it is not propius that fishes plow:frown:

Thank you in advance