gtsolid

Guest

Bye to all,

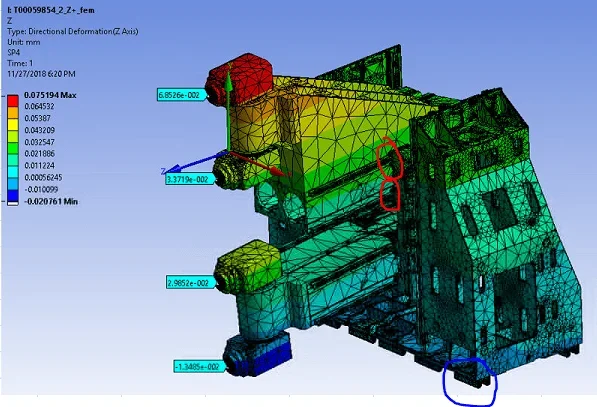

I'm modeling a complex structure, where the most yielding component, in my view, is the recirculation skates.

I can simulate their yield through a elastic support And I know the results are approaching reality.

All this works until I have a support on the edge of the model.

If instead you want to recreate something like that between skates within the same, how can I simulate them?

Could I impose a material with a lower elastic module on skates, or do you have better suggestions?

I'm modeling a complex structure, where the most yielding component, in my view, is the recirculation skates.

I can simulate their yield through a elastic support And I know the results are approaching reality.

All this works until I have a support on the edge of the model.

If instead you want to recreate something like that between skates within the same, how can I simulate them?

Could I impose a material with a lower elastic module on skates, or do you have better suggestions?