Alex_M

Guest

Good evening to all,

I hope I have taken the right section!

I would like to point out that I am completely acerbic in using these software but I have in mind to make two projects and I need to understand which program to start studying to achieve what I have mind!

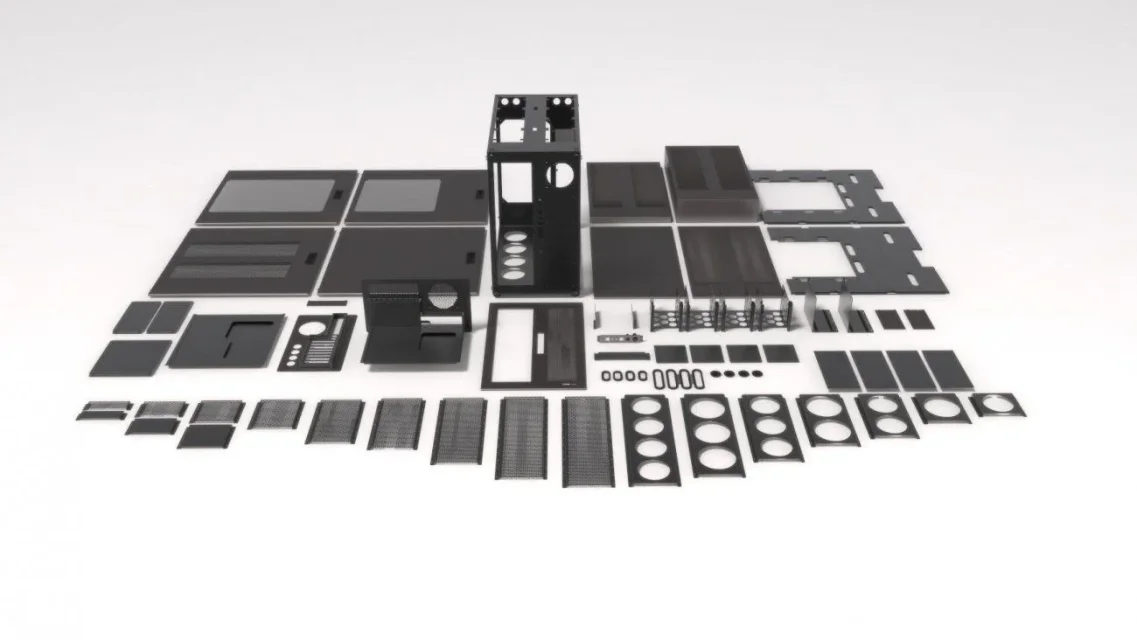

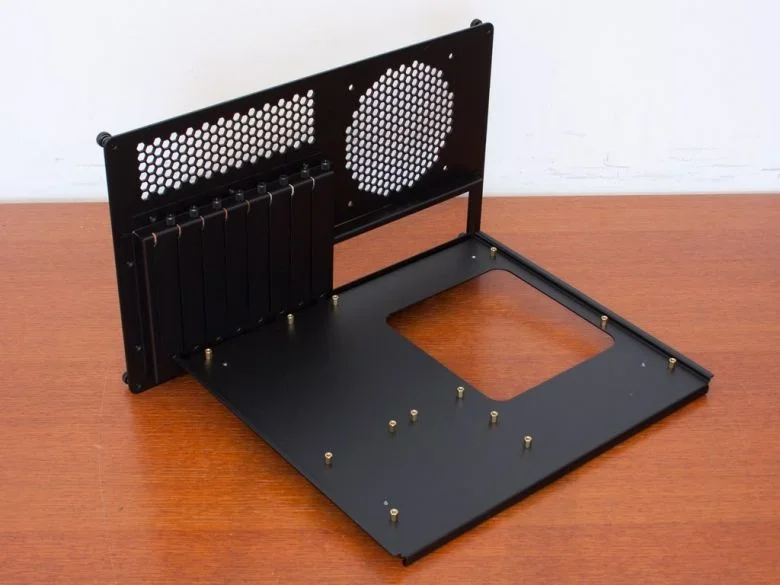

I am a computer enthusiast and I need to design and draw a case per pc a little particular, consisting of various pieces and then let me cut it to the cnc.

I need to draw the various sheet metal parts with related hooks, folds, holes with thread and inks.

I was wondering which program is most suitable for my purpose and I was evaluating inventor, but honestly I don't know if it then allows me to pull out the ready files for the cnc or I have to pass for other software. the thing that attracts me particularly of inventor is the possibility (correct me if I am mistaken) to draw the pieces and then “assemble them” and see if they match the various holes, the pits and the various screws, as well as to see visually how the finished project would come. I was seeing autocad and autocad mechanical... I mean, I'm in the high sea and I hope you can direct me!

thanks in advance,

alessandro

I hope I have taken the right section!

I would like to point out that I am completely acerbic in using these software but I have in mind to make two projects and I need to understand which program to start studying to achieve what I have mind!

I am a computer enthusiast and I need to design and draw a case per pc a little particular, consisting of various pieces and then let me cut it to the cnc.

I need to draw the various sheet metal parts with related hooks, folds, holes with thread and inks.

I was wondering which program is most suitable for my purpose and I was evaluating inventor, but honestly I don't know if it then allows me to pull out the ready files for the cnc or I have to pass for other software. the thing that attracts me particularly of inventor is the possibility (correct me if I am mistaken) to draw the pieces and then “assemble them” and see if they match the various holes, the pits and the various screws, as well as to see visually how the finished project would come. I was seeing autocad and autocad mechanical... I mean, I'm in the high sea and I hope you can direct me!

thanks in advance,

alessandro