You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

teseo

Guest

MassiVonWeizen

Guest

What doesn't suit you or you don't like?

Does it matter with solid?

Does it matter with solid?

teseo

Guest

Sorry I think I've got the wrong forum section... the habit

I ask administrators to move discussion I ask vein.. .

However returning to us is the design in general seems me disorderly,I do not convince myself of the quotation that I put,I doubt that the miller understands what to do.... .

in fact with solid does not really hit a pippa.... .

Hi.

I ask administrators to move discussion I ask vein.. .

However returning to us is the design in general seems me disorderly,I do not convince myself of the quotation that I put,I doubt that the miller understands what to do.... .

in fact with solid does not really hit a pippa.... .

Hi.

MassiVonWeizen

Guest

depends on what you have to quote.

the construction of the placement/saving of the pipe fitting?

a design for the definition of various elements and welding?

of mechanical processing?

Control quotas?

the construction of the placement/saving of the pipe fitting?

a design for the definition of various elements and welding?

of mechanical processing?

Control quotas?

teseo

Guest

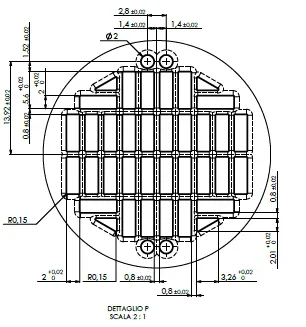

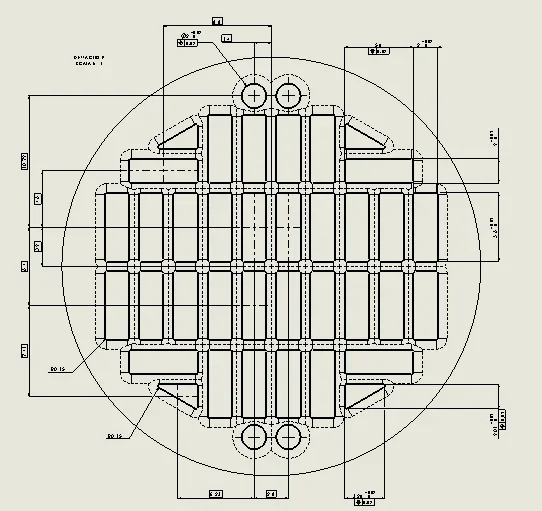

It's a mechanical piece that on a face involves that milling and/or wire...unfortunately I can't post more.....of the design... imagine having a plate and on that plate you have to make those holes with those shapes like the odds??? ? how I quoted them can go or not....

Hi.

Hi.

MassiVonWeizen

Guest

I'd hide what's under there that has nothing to do with it.

I would quota everything from the edges of the holes and not from hypothetical centers, but for me you have to quota every single cut otherwise as the miller does to know what measures they have

I would quota everything from the edges of the holes and not from hypothetical centers, but for me you have to quota every single cut otherwise as the miller does to know what measures they have

teseo

Guest

Okay.

I did not quote all the cuts because they are all fair I have quoted one by group..... .

Anyway I'm quoting everything....

Hi.

I did not quote all the cuts because they are all fair I have quoted one by group..... .

Anyway I'm quoting everything....

Hi.

MassiVonWeizen

Guest

If you don't specify the miller how you know?are all fair

this is however valid for a mechanical processing design and with the milling machine that makes the tool positioning or if you do not know how it will be produced

If you make it to laser cutting, water or similar you don't need quotas if not some control

teseo

Guest

how to produce it we decide it together cutting thread... .

Hi.

Hi.

meccanicamg

Guest

I would put two quotas with the tolerances of the things they serve and for all the rest I would write the note: request to the technical office the dxf or equivalent to realize.

end of history.

so much.... we are no longer able to put on the table... and also to read the drawings there are certain inventions. ..thinks that one calls me for a 120mm radius design indicated and asks me: But how much is the diameter? from the third grade is double....

end of history.

so much.... we are no longer able to put on the table... and also to read the drawings there are certain inventions. ..thinks that one calls me for a 120mm radius design indicated and asks me: But how much is the diameter? from the third grade is double....

MassiVonWeizen

Guest

then give it to an automatic machine that reads a cutting dxf or parasolid, not pdf.wire cut

if it is so all those odds serve only to make the eye of the customer happy; as mechanicalmg says put those control, those tolerated and just

teseo

Guest

So it could be okay how it was?

teseo

Guest

I would like to try to stay among those that a not too complicated table can do..... .I would put two quotas with the tolerances of the things they serve and for all the rest I would write the note: request to the technical office the dxf or equivalent to realize.

end of history.

so much.... we are no longer able to put on the table... and also to read the drawings there are certain inventions. ..thinks that one calls me for a 120mm radius design indicated and asks me: But how much is the diameter? from the third grade is double....

Hi.

czar

Guest

in general for symmetric pieces both on x axis and y, quoto the entirety between the elements being under understood that the distance between an element and the x axis is symmetric.