Fabrizio Magi

Guest

Bye to all,

I have a doubt about the use of geometric tolerances of symmetry. I always use a single plan like datum (or axis in a 2d view) not to stumble into misunderstandings.

But I happen to see in some drawings even more than one datum, for example two perpendicular planes between them or two parallel axes between them.

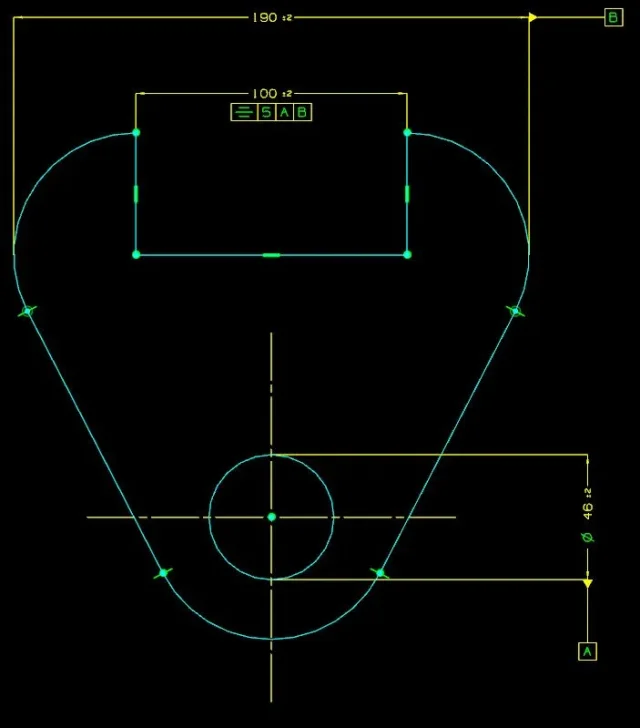

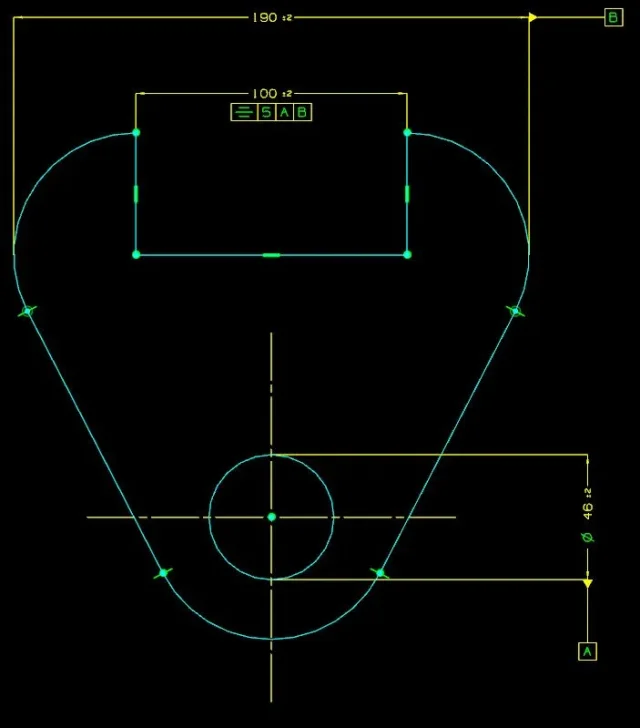

according to you is correct quotation in figure 1? I honestly would have quoted symmetrical compared to only a. But I could understand who says that symmetry is compared to the plane formed by the axis to and from the median point of the b.

I have a doubt about the use of geometric tolerances of symmetry. I always use a single plan like datum (or axis in a 2d view) not to stumble into misunderstandings.

But I happen to see in some drawings even more than one datum, for example two perpendicular planes between them or two parallel axes between them.

according to you is correct quotation in figure 1? I honestly would have quoted symmetrical compared to only a. But I could understand who says that symmetry is compared to the plane formed by the axis to and from the median point of the b.