meccanicamg

Guest

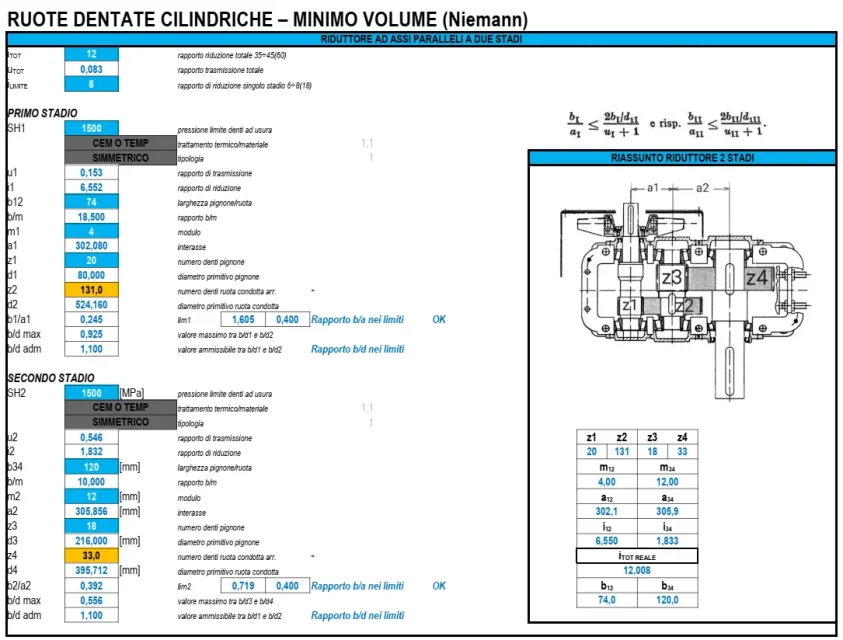

by reasoning we can say that:

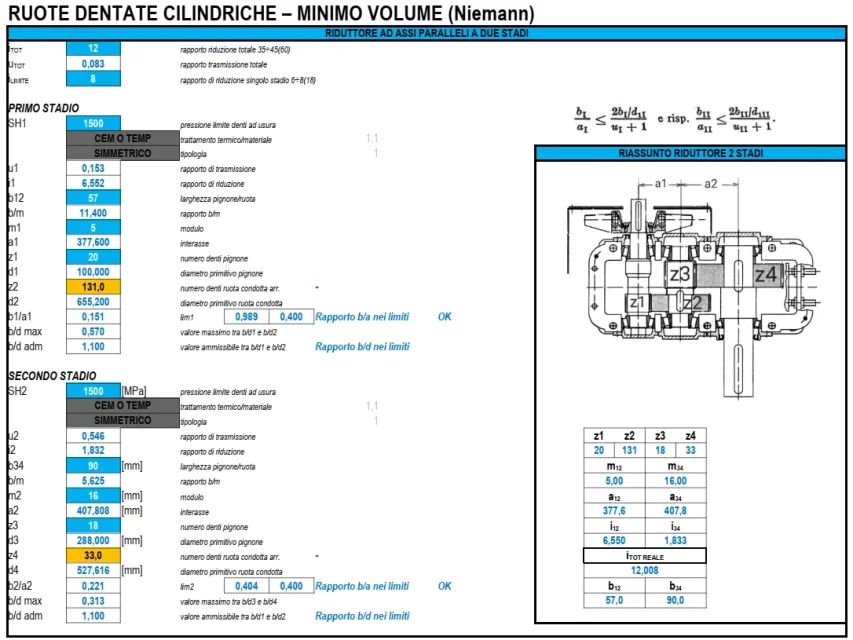

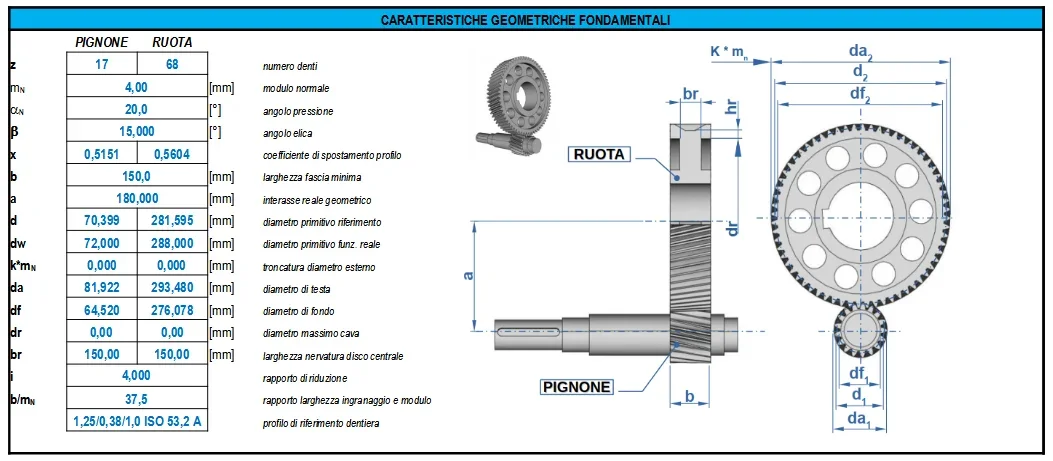

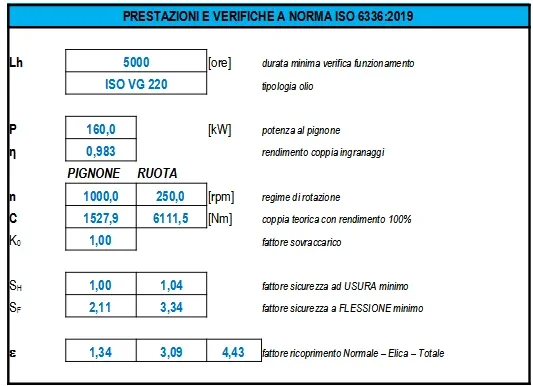

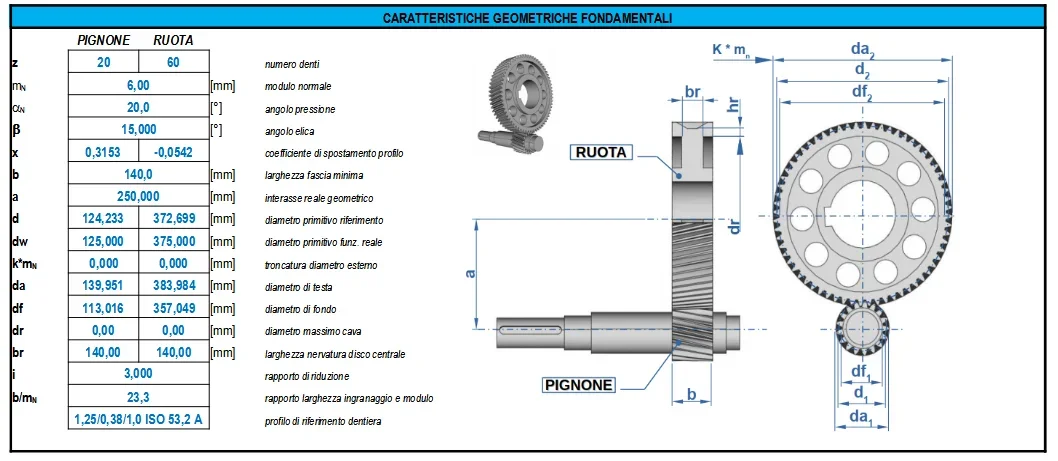

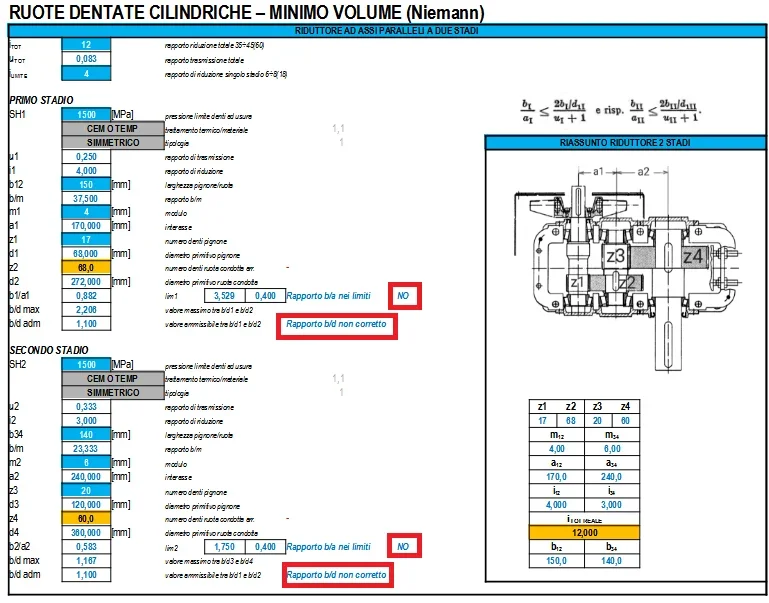

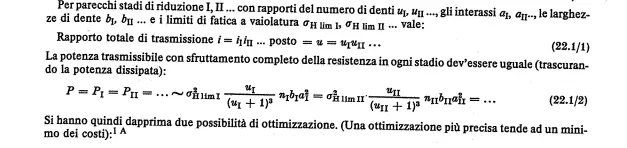

- if all gears are cemented and hardened, they have the maximum mechanical characteristics and by force of things we will have smaller wheels and pinions than only hardened materials or only reclaimed. So having 2 stages with the same sigmah is fine.

- other thing is definitely that the number of pinion teeth must be as little as possible to and have the module just verified to have a minimum volume

- clearly if increasing the module for hertz needs will decrease the band width but equal teeth increases the volume of the outer diameter

- if increase the band to improve hertz does not increase the diameter but increase the cylinder height and then increase the volume

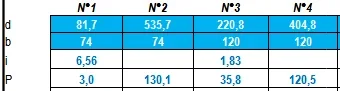

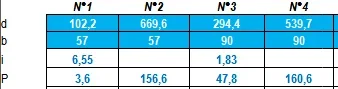

In fact, complete verification should be made in accordance with and tabulate all the options....only so is the minimum volume, that is one absolute couple that meets the criterion. I believe how you are doing now you are looking among the minimum possible volumes but not in the absolute minimum.

well all in all better than to shoot at case m1=10 and m2=20.... that then comes out a huge reducer like a house.

- if all gears are cemented and hardened, they have the maximum mechanical characteristics and by force of things we will have smaller wheels and pinions than only hardened materials or only reclaimed. So having 2 stages with the same sigmah is fine.

- other thing is definitely that the number of pinion teeth must be as little as possible to and have the module just verified to have a minimum volume

- clearly if increasing the module for hertz needs will decrease the band width but equal teeth increases the volume of the outer diameter

- if increase the band to improve hertz does not increase the diameter but increase the cylinder height and then increase the volume

In fact, complete verification should be made in accordance with and tabulate all the options....only so is the minimum volume, that is one absolute couple that meets the criterion. I believe how you are doing now you are looking among the minimum possible volumes but not in the absolute minimum.

well all in all better than to shoot at case m1=10 and m2=20.... that then comes out a huge reducer like a house.