Davimont

Guest

a good day to all

I don't understand much, so I'm here asking for advice.

premise: I do not want to size the various components because it is not my job but only to understand what solution to propose to the maintainer who is dealing with the assembly.

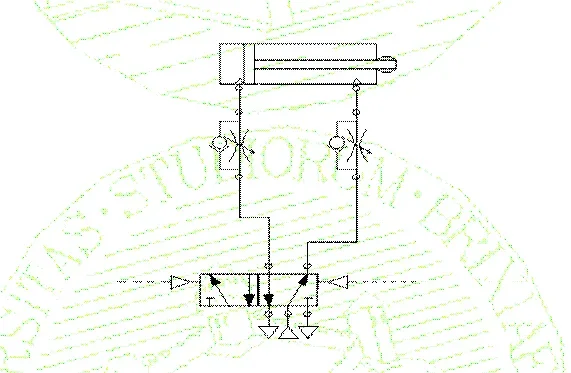

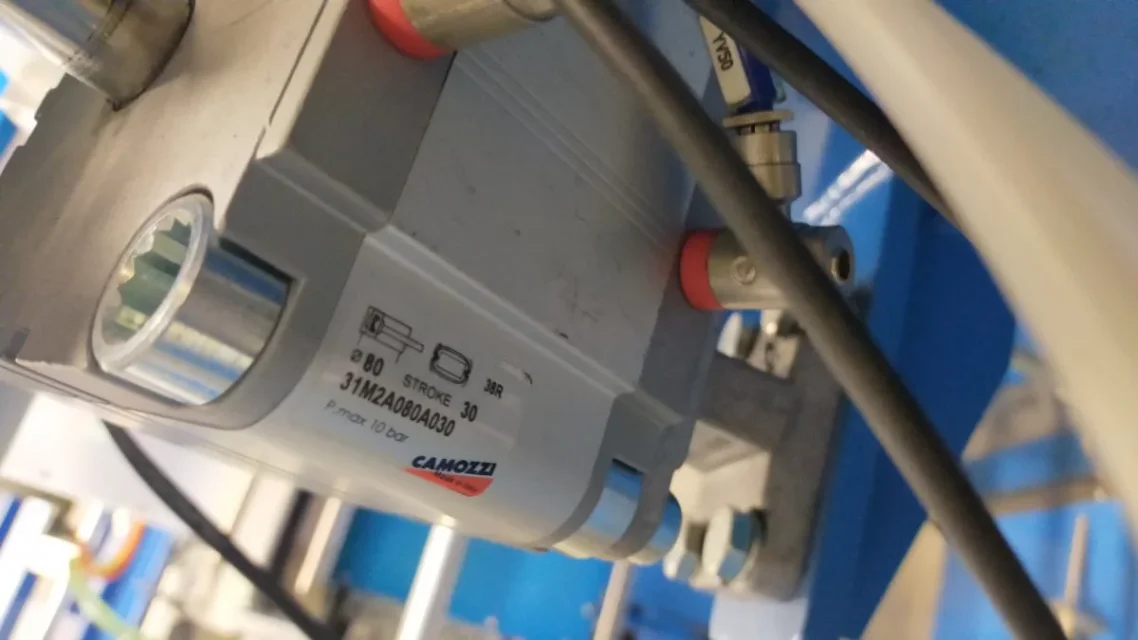

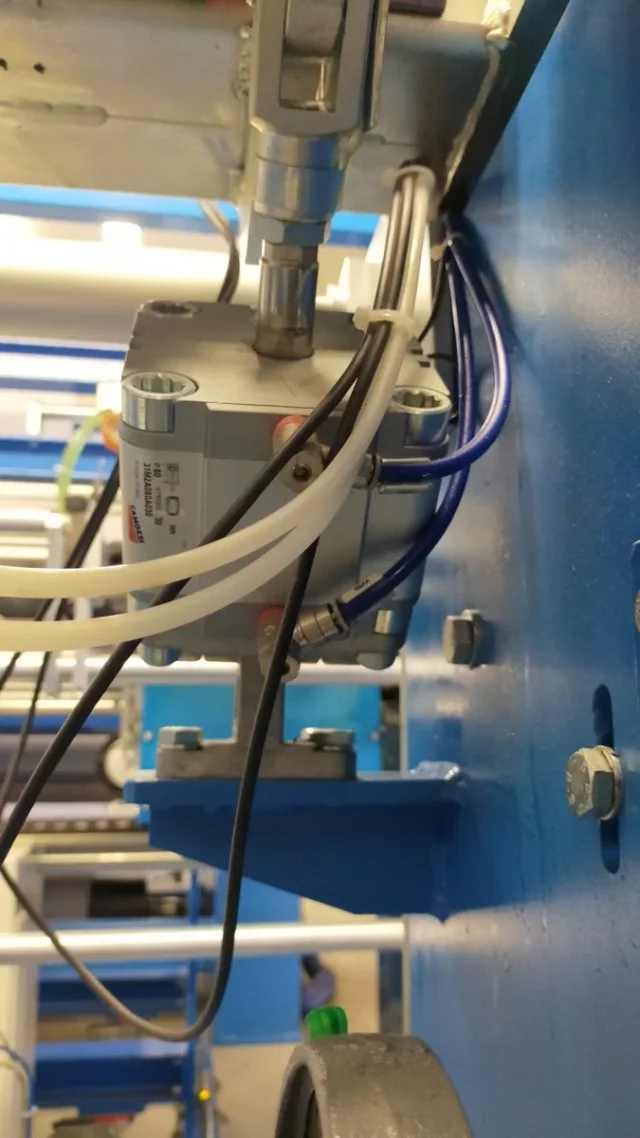

I have a small existing structure (type lever bridge but with movement of about 10 degrees upward) that rises and falls thanks to two pneumatic pistons.

to this structure have added components to optimize a certain processing.

Now the problem.

the new components add weight to the system, from 30kg to lift with the original pistons now we have passed to about 50kg. the pistons lift the structure however but at the time of lowering it they can no longer shock the descent and then they knock everything on the machine below.

they do not want to replace the original pistons for reasons I ignore.

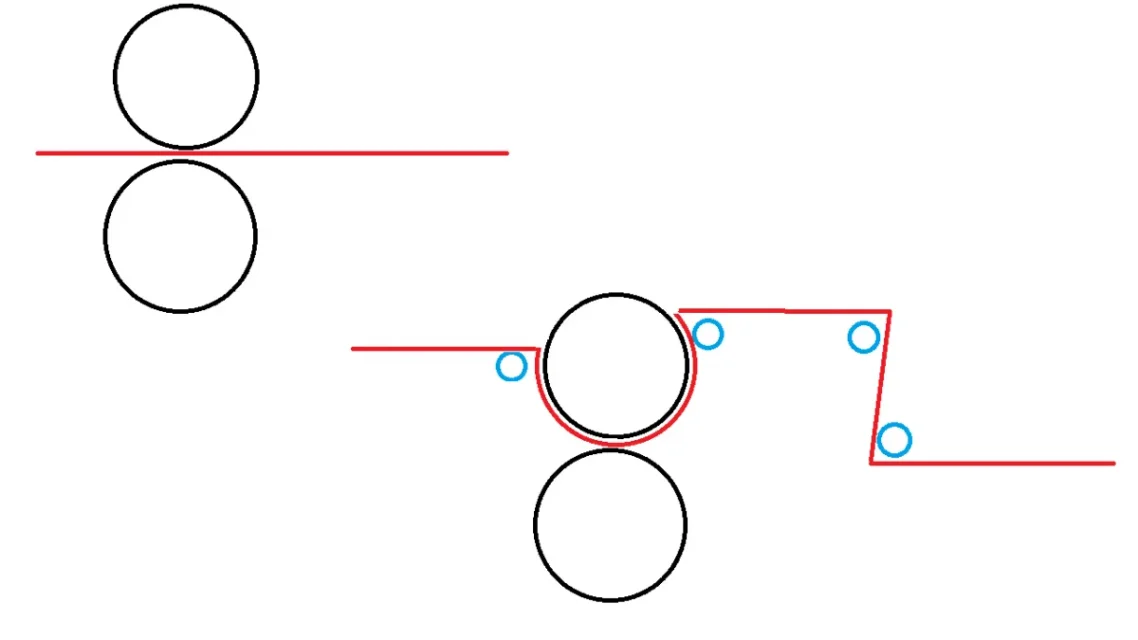

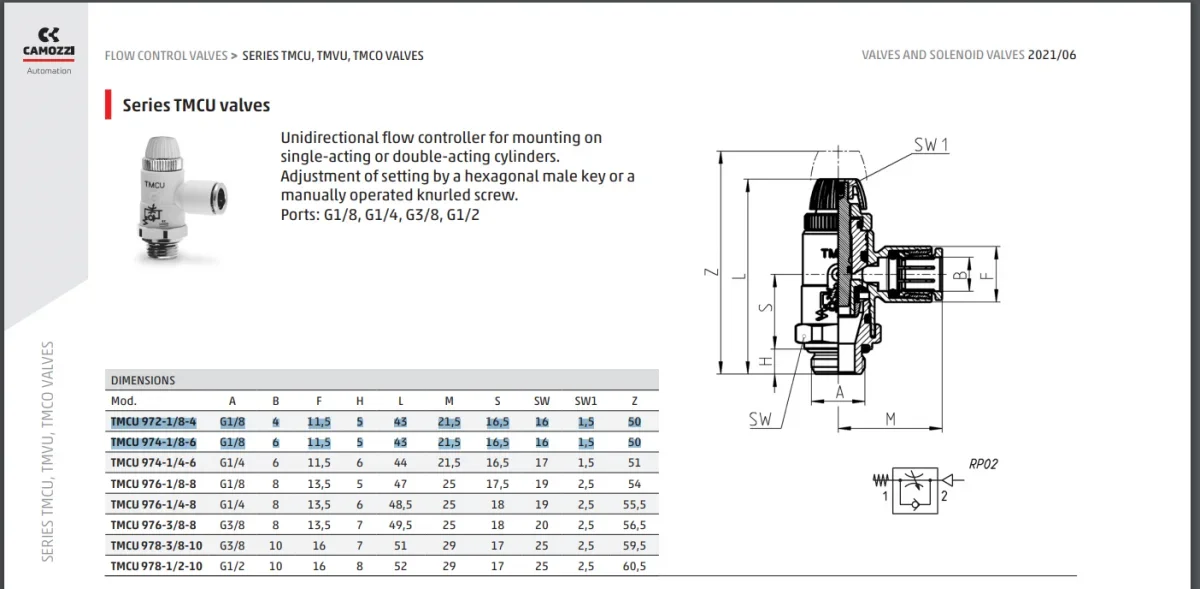

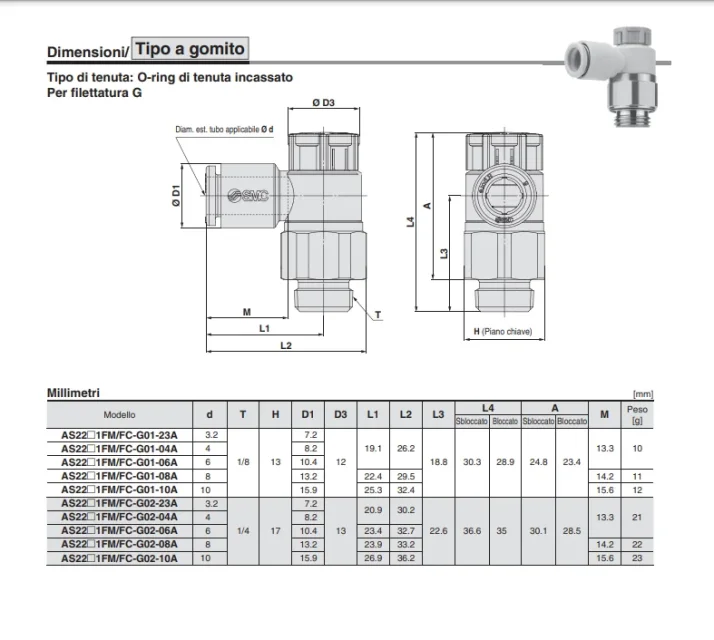

I've proposed dampers at the end of the race or flow regulators but it's not that I know exactly what I'm talking about, it's things I've never treated.

without more precise data perhaps it is impossible to propose a solution but to raise some advice on which components to evaluate I would be comfortable.

What could I propose to solve the problem?

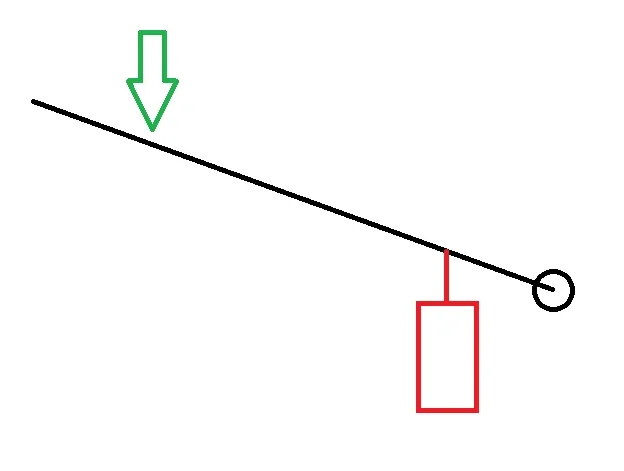

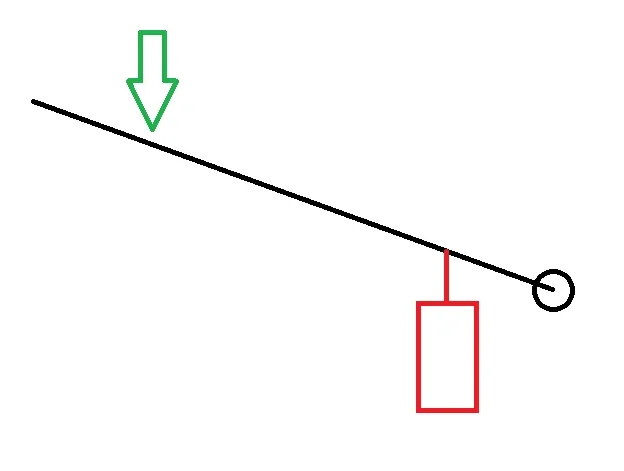

place a very basic scheme made quickly with paint just to make the idea. in red the piston that raises and lowers the structure and in green the force that I have to fight to prevent the all anticipated without control.

I don't understand much, so I'm here asking for advice.

premise: I do not want to size the various components because it is not my job but only to understand what solution to propose to the maintainer who is dealing with the assembly.

I have a small existing structure (type lever bridge but with movement of about 10 degrees upward) that rises and falls thanks to two pneumatic pistons.

to this structure have added components to optimize a certain processing.

Now the problem.

the new components add weight to the system, from 30kg to lift with the original pistons now we have passed to about 50kg. the pistons lift the structure however but at the time of lowering it they can no longer shock the descent and then they knock everything on the machine below.

they do not want to replace the original pistons for reasons I ignore.

I've proposed dampers at the end of the race or flow regulators but it's not that I know exactly what I'm talking about, it's things I've never treated.

without more precise data perhaps it is impossible to propose a solution but to raise some advice on which components to evaluate I would be comfortable.

What could I propose to solve the problem?

place a very basic scheme made quickly with paint just to make the idea. in red the piston that raises and lowers the structure and in green the force that I have to fight to prevent the all anticipated without control.